Typical application circuit, Supply bypassing, layout, and grounding, Wlp applications information – Rainbow Electronics MAX98500 User Manual

Page 13

______________________________________________________________________________________ 13

MAX98500

Boosted 2.2W Class D Amplifier

with Automatic Level Control

Supply Bypassing, Layout, and Grounding

Proper layout and grounding are essential for optimum

performance. Use a large continuous ground plane on

a dedicated layer of the PCB to minimize loop areas.

Connect AGND and BSTPGND/SPKPGND directly to the

ground plane using the shortest traces length possible.

Proper grounding improves audio performance, and

prevents any digital noise from coupling into the analog

audio signals.

Bypass V

BAT

with a 10FF capacitor and a system

bulk capacitance of 22FF or larger. Bypass PVDD to

SPKPGND with a 0.1FF capacitor and with as minimal a

loop area as possible. Connect SPKP and SPKN to the

speaker using the shortest and widest traces possible.

Reducing trace length minimizes radiated EMI. Route

SPKP/SPKN as a differential pair on the PCB to minimize

loop area, thereby, the inductance of the circuit. If filter

components are used on the speaker outputs, be sure

to locate them as close as possible to the MAX98500 to

ensure maximum effectiveness. Minimize the trace length

from any ground-tied passive components to SPKPGND

to further minimize radiated EMI.

An evaluation kit (MAX98500 Evaluation Kit) is available

to provide an example layout for the MAX98500.

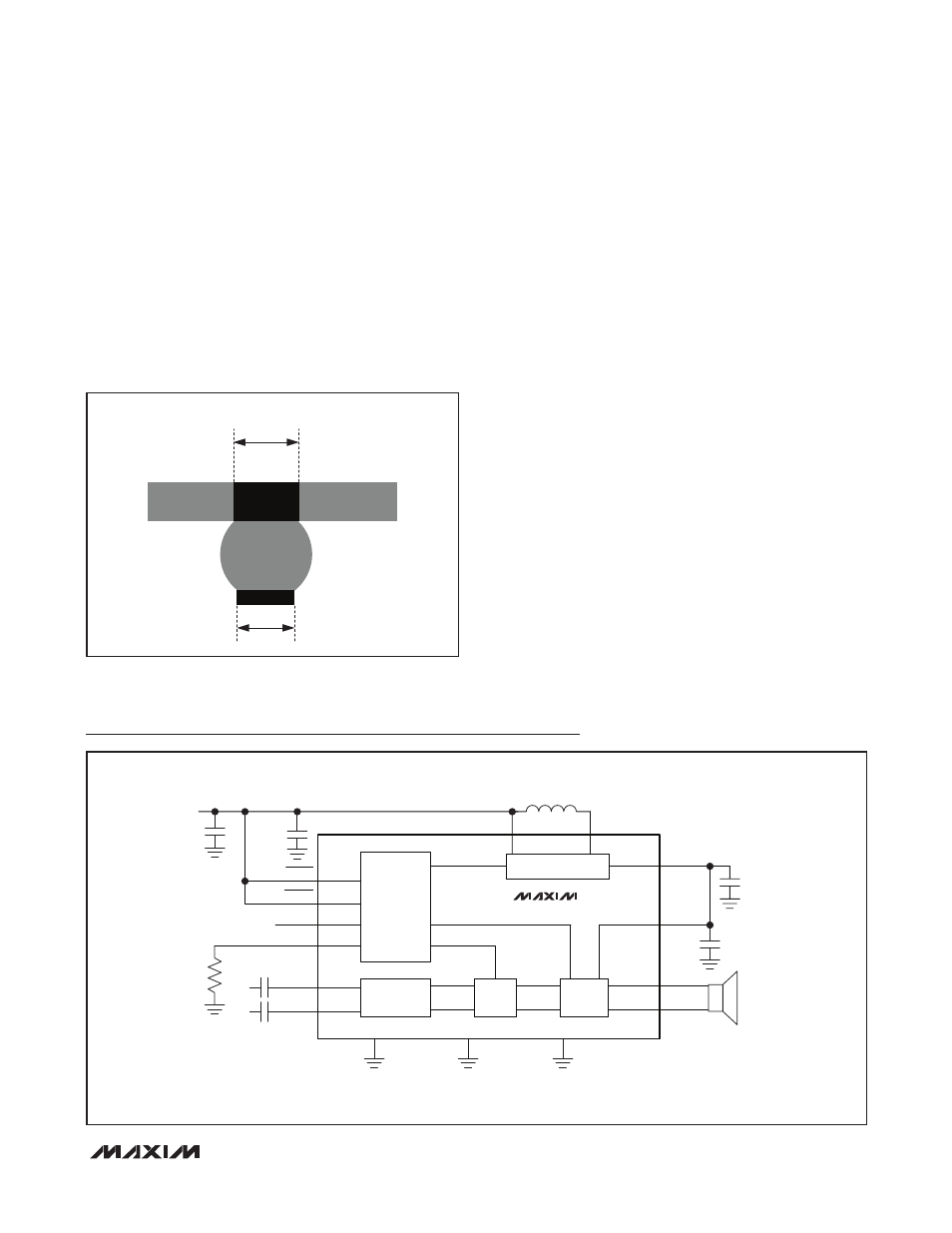

WLP Applications Information

For the latest application details on WLP construction,

dimensions, tape carrier information, PCB techniques,

bump-pad layout, and recommended reflow tempera-

ture profile, as well as the latest information on reliability

testing results, refer to the Application Note 1891: Wafer-

Level Packaging (WLP) and Its Applications on Maxim’s

website at www.maxim-ic.com/ucsp. See Figure 4 for the

recommended PCB footprint for the MAX98500.

Figure 4. Recommended PCB Footprint

Typical Application Circuit

0.25mm

0.22mm

CONTROL

DIFFERENTIAL

INPUT

BOOST CONVERTER

GAIN

OUTPUT

STAGE

BATTERY

SPKP

SPKN

PVDD

8I

V

CCOUT

LX

V

BAT

22µF*

27.4kI

1%

C

IN

1µF

C

IN

1µF

*SYSTEM LEVEL REQUIREMENT

AGND

SPKPGND

BSTPGND

C4

A4

D1, C2

D3

RKNEE B3

GAIN B2

SDSPK C3

SDBST D4

B4

A3

A2

A1

B1

C1

C

VBAT

10µF

0805

10%

2.2µH

20%

INP D2

INN

MAX98500

C

VCCOUT

22µF

0805

10%

0.1µF

10%