Bolting and hardware requirements, Identifying bolt grades, Bolting requirements – Grain Systems Tanks PNEG-2135 User Manual

Page 19

5. Bolting Requirements

PNEG-2135 Construction Manual for 2.66" Corrugation 135' Diameter Tank

19

Bolting and Hardware Requirements

Identifying Bolt Grades

NOTE: Bolts should not be tightened in excess of the torque specifications in below

.

Hardware usage is detailed in the bolting requirement charts

, stiffener and splice hardware

charts

and the bolting and the hardware requirements section.

Torque (ft. lbs.)

Bolt Size

Minimum

Maximum

5/16"-18

15

20

3/8"-16

35

42

7/16"-14

65

72

1/2"-13

95

105

Under no condition shall any other bolts be substituted for those supplied by GSI.

CAUTION

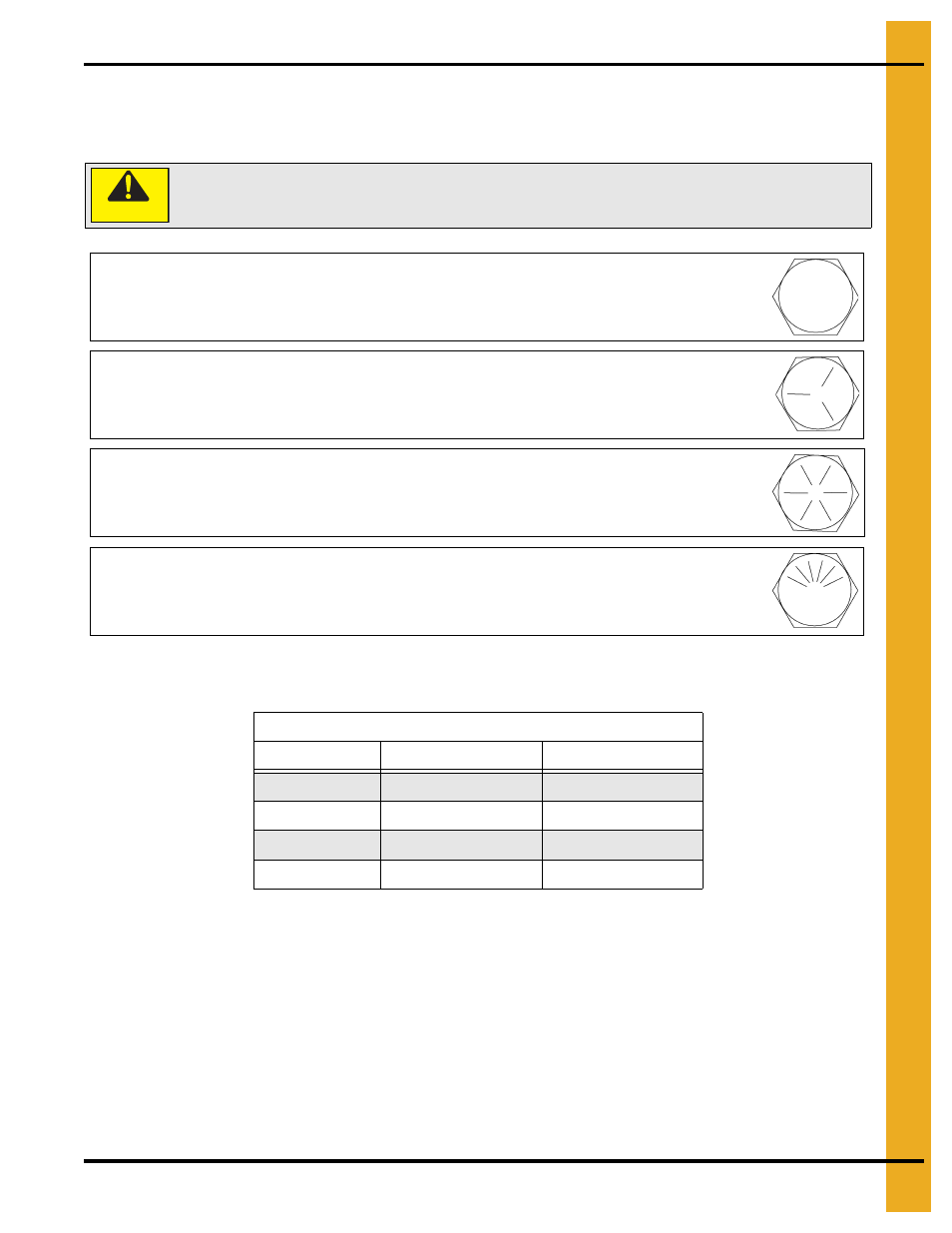

Grade 2 Bolts

Grade 2 bolts are designated with a plain head and are not used in GSI grain bins/silos.

Grade 5 Bolts

Grade 5 bolts are designated by three (3) slash marks on the head. All 5/16" diameter

bolts are to be grade 5 or higher.

Grade 8 Bolts

Grade 8 bolts are designated by six (6) slash marks evenly spaced out around the head

of the bolt.

Grade 8.2 Bolts

Grade 8.2 bolts are designated by six (6) slash marks on the head in a sunrise pattern.

All 3/8" and 7/16" diameter bolts are to be grade 8 or grade 8.2.