Banks Power Cummins Motorhomes: (Diesel ’93 - 98 B5.9L & C8.3L) PowerPack & Stinger systems w_Twin Ram Manifold 5.9L, 190-210-230-hp rated User Manual

Page 8

GAUGE LIGHTING

connect the 4-pin connector of each gauge

into the back of its corresponding gauge.

A. crimp the remaining black and red wires

from each 4-pin connector gauge harness to the

butt connectors as shown in Figure 4.

B. strip one end of the reD wire and crimp it to

the butt connector containing the reD wires from

step ‘a’.

C. strip one end of the black wire and crimp it

to the butt connector containing the black wires

from step ‘a’.

D. route the red wire to the fuse box. locate

the appropriate fuse for instrument lighting in the

owner’s manual. cut the red wire as required

and strip the end. crimp the push on connector

to the reD wire and connect to the fuse as shown

in Figure 4. alternatively, locate power wire to

dimmer switch and install T-tap. cut the red wire

as required and strip the end. crimp the push on

T-tap connector to the reD wire and connect to

T-tap on dimmer power wire.

E. locate a metal surface that will serve as an

acceptable chassis ground. cut the black wire to

a sufficient length that will allow it to reach the

chassis ground and strip the end crimp the ring

terminal to the black wire ash shown in Figure 4.

F. Drill a 1/8” hole, if required, to attach the ring

terminal to the chassis ground.

Caution: If drilling, check the backside to

make sure there are no components that may

be damaged by drilling.

G. use the supplied self-tapping screw to secure

the ring terminal to the chassis ground.

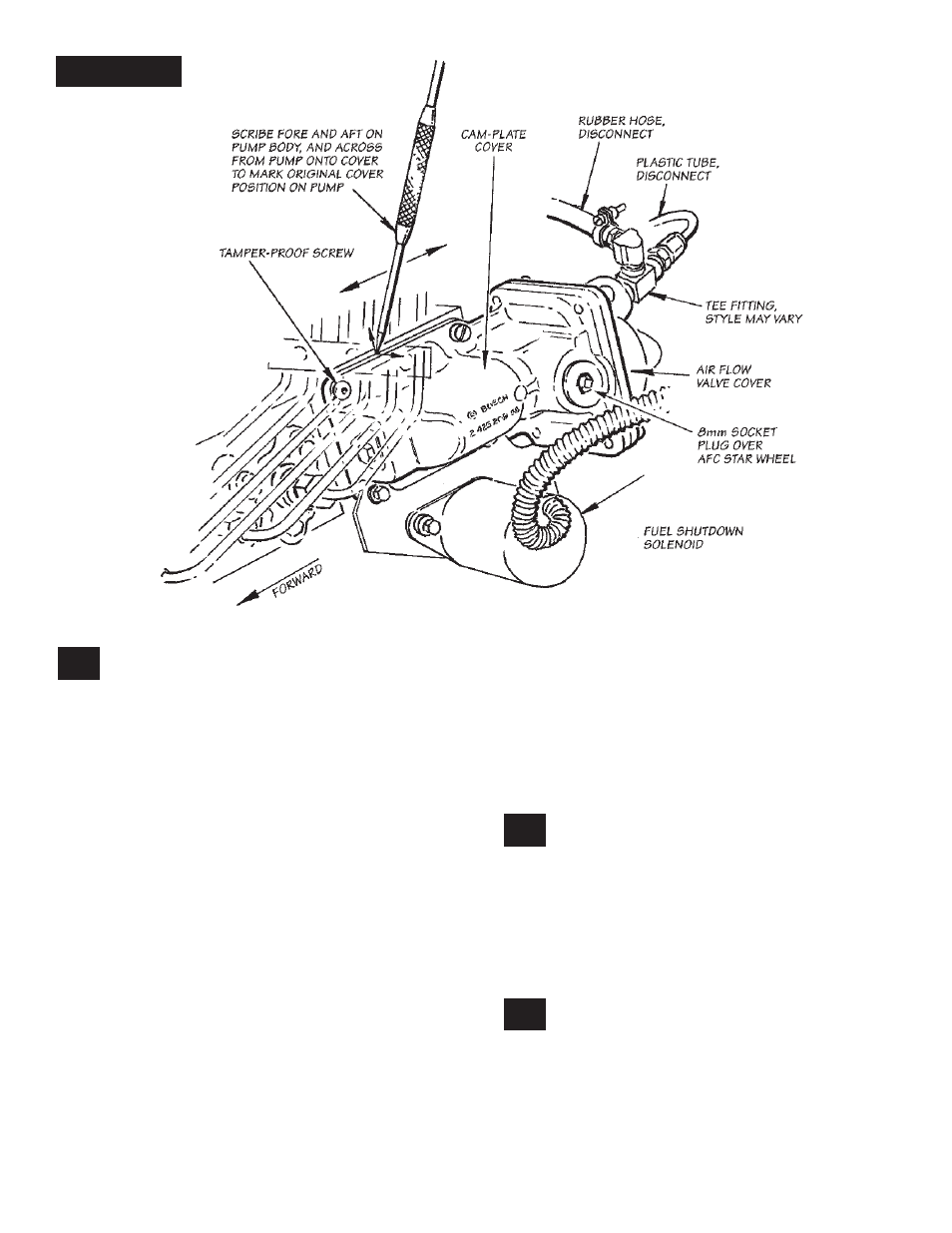

OTTOMIND INSTALLATION

To realize power gains made available by

the increased airflow through the banks

components, the fuel delivery of the injection

pump must also be increased. This procedure

will provide the additional fuel flow required.The

injection pump is located on the upper left side of

the engine, and can be identified by the row of six

injector pressure tube connections on top of the

pump body.

loosen the upper hose clamp on the boost

tube hose joint at the intake manifold

inlet casting. remove the hose from the inlet

casting and push out of the way. cover the intake

manifold opening and the open end of the boost

tube with clean rags to prevent foreign object

entry.

34.

35.

33.

p.n. 96385

8

Figure 5