Banks Power Cummins Motorhomes: (Diesel ’93 - 98 B5.9L & C8.3L) PowerPack & Stinger systems w_Twin Ram Manifold 5.9L, 190-210-230-hp rated User Manual

Page 12

engaged on the manifold adapter and the clamp is

positioned properly on the hose, then tighten the

clamp nut.

For Stinger installation, proceed to CHECkING

ENGINE PERFORMANCE.

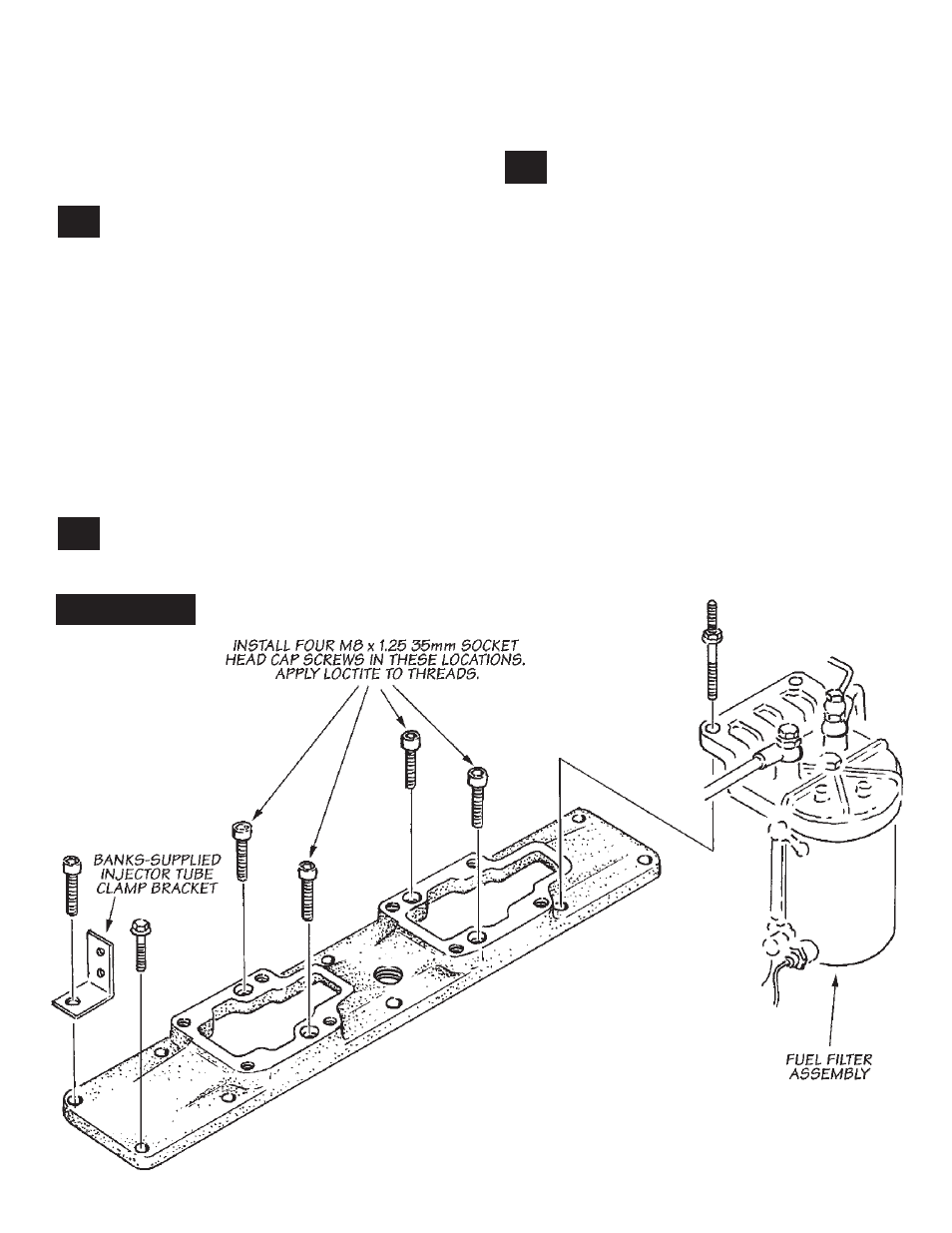

TWINRAM MANIFOLD INSTALLATION

loosen the tube nuts at both ends of all

six fuel injection lines. remove the two

bolts from the intake manifold cover that retain

the fuel injection line clamp brackets. remove

the injection lines as an assembly. it is very

important that no dirt or debris be introduced

to the fuel system while the injector lines are

removed. place the plastic caps provided over

each injector nozzle and each fitting on the

injection pump. set the injector lines aside in

a clean place. remove the remaining manifold

cover bolts and remove the remaining manifold

cover bolts and remove the manifold cover. Make

note of various bolt lengths and their locations.

cover the cavity in the cylinder head with clean

rags to keep foreign material out while working.

clean any remaining gasket residue from the

cast iron surface of the cylinder head. Take

care to keep the gasket material from entering the

cylinder head cavity. remove any rags placed in the

head cavity at this time to allow for the installation

of the Twinram manifold components.

if your motorhome is equipped with an air

compressor, the inlet air for the compressor

may be drawn from the intake manifold. a fitting

and a length of hose are provided for adaptation

to accomodate the compressor feed. install the

air compressor feed fitting in the large threaded

hole in the Twinram base plate. if your engine

does not take air from the intake manifold, install

the pipe plug provided in the threaded hole. place

the new gasket provided over the bolt pattern

in the cylinder head and place the base plate in

position. apply a drop of loctite to the threads

of four metric socket-head capscrews provided

and install into the recessed holes in the base

plate. see Figure 9

.

install ten factory fasteners

finger tight in the remaining positions. note the

location of two slightly longer factory fasteners

for mounting the fuel filter bracket. also note the

location of the new injection line bracket provided.

51.

52.

53.

Figure 9

12

p.n. 96385