Banks Power Cummins Motorhomes: (Diesel ’93 - 98 B5.9L & C8.3L) PowerPack & Stinger systems w_Twin Ram Manifold 5.9L, 190-210-230-hp rated User Manual

Page 15

15

p.n. 96385

it may be necessary to slightly bend one injector

tube to clear the front corner of the forward heater

housing. The injector tube must not contact the

housing after assembly. bend the tube as little as

possible to obtain about

1

⁄

16

-inch clearance to the

housing. use a smooth, rounded-edge pry tool to

avoid nicking or gouging the tube.

slip a

3

⁄

8

washer on one of the

3

⁄

8

x 5-inch hex

bolts, then apply a drop of loctite to the first

few threads and slide the bolt into the rearmost

long bolt hole on the banks Twinram manifold.

set an air inlet manifold gasket on top of each

heater housing, then set the Twinram manifold

in place while guiding the bolt through the heater

housing and gaskets. use extreme care not to tear

or damage the gaskets while installing the bolts

as boost leaks can occur. Thread the bolt into the

baseplate finger–tight, then install washers and

apply loctite to the ramaining three 5- inch and four

3-inch

3

⁄

8

hex bolts before threading them through

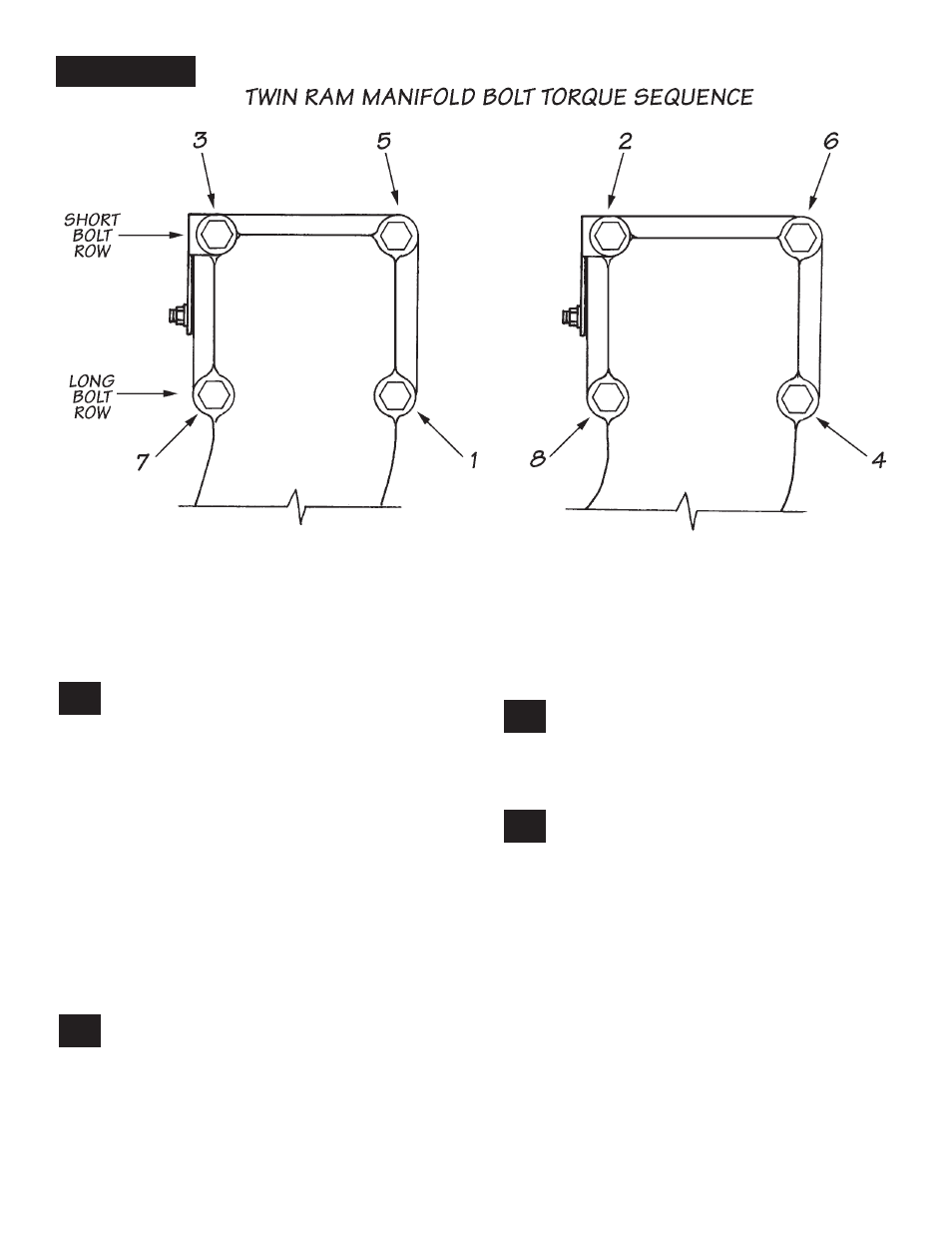

the manifold, heater housings and gaskets. Torque

bolts in the pattern shown in Figure 12. Tighten all

eight bolts to 20 lb-ft. , then in 5 lb-ft. increments to

35 lb-ft., each time using the pattern shown.

Once the bolts are torqued, slide one of

the factory injector tube spacers between

the rear heater housing and the three injector

tubes, so that the spacer is positioned over the

two threaded holes in the housing. install the other

factory spacer half, and the factory clamp plate

to the heater housing using two 10 - 24 x 1–inch

bolts. When tightening the bolts, adjust the position

of the clamp assembly to center the heater coil

ground nut between the tubes. The tubes must not

be allowed to vibrate against this nut. Once this

position has been established, remove each bolt

one at a time, apply loctite and tighten.

Tighten all 12 injector tube nuts to 22 lb-ft.

using a 19mm or

3

⁄

4

-inch crow’s–foot wrench

on a torque wrench. install factory injector tube

clamp hardware onto the new bracket at the front

of the baseplate and tighten.

loosen the hose clamp at the intercooler

end of the factory boost tube and remove

the boost tube. install the new boost tube

provided. rotate the tube such that the bend is

aligned properly with the inlet to the Twinram

manifold and install with the hump hose provided.

retighten all the hose clamps. bolt the dipstick

tube and bracket to the top of the Twinram

manifold using the factory bolt.

56.

57.

58.

59.

Figure 12