Banks Power Cummins Motorhomes: (Diesel ’93 - 98 B5.9L & C8.3L) PowerPack & Stinger systems w_Twin Ram Manifold 5.9L, 190-210-230-hp rated User Manual

Page 6

install the air inlet tube (from the air cleaner

housing) and the turbo exhaust pipe onto

the turbocharger. reattach the wastegate actuator

boost line using a crimp lock clamp provided.

GAUGE INSTALLATION

choose a suitable location under the

lower edge of the dash panel for mounting

the instrument panel provided where it can be

conveniently viewed by the driver.

Note: Molded instrument consoles for top-

of-dash mounting and additional gauges are

available through Gale Banks engineering.

using the panel as a template, drill two

3

⁄

16

”

diameter holes in the dash and mount the

panel with two no. 10 x

1

⁄

2

” machine screws, nuts

and star washers provided.

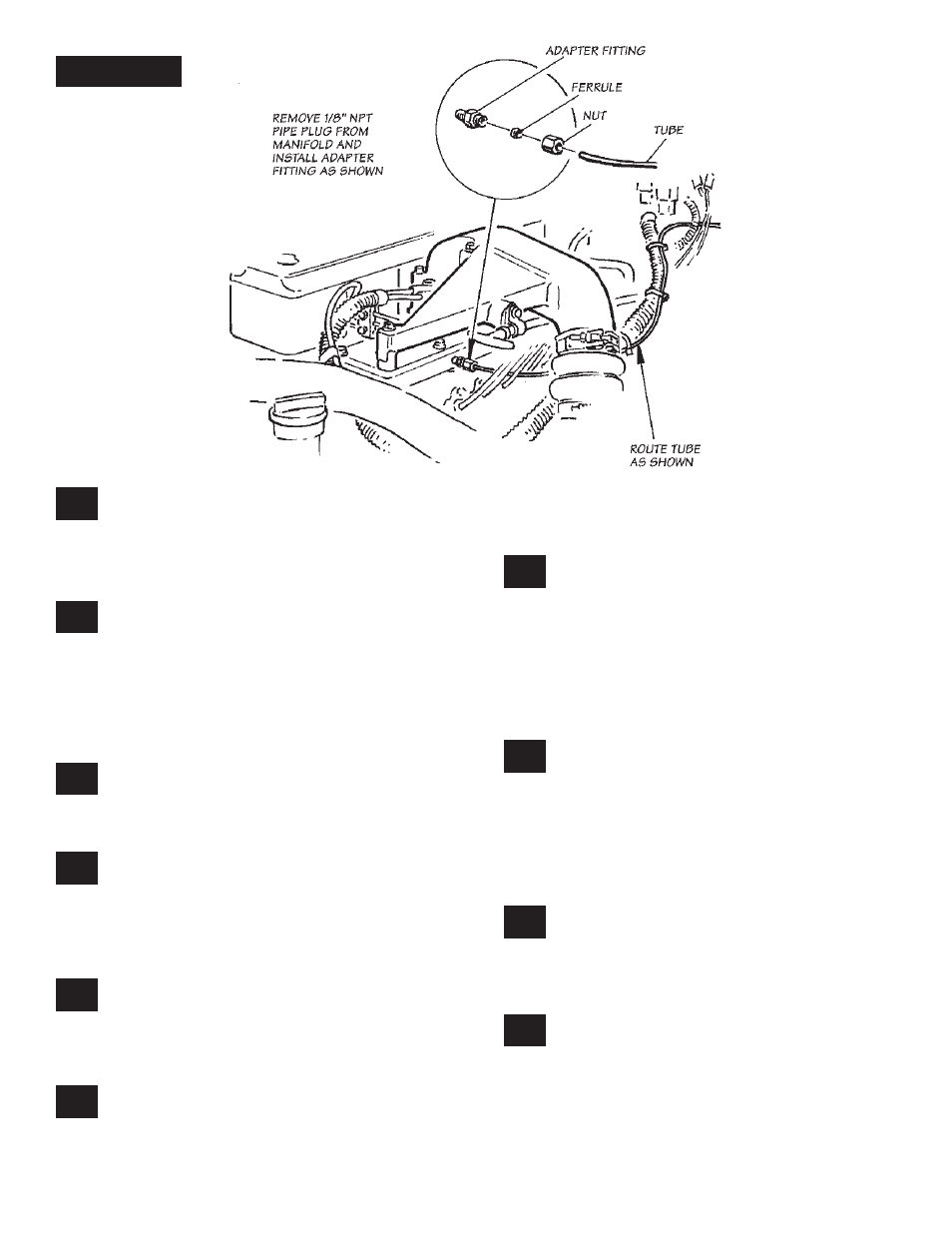

locate and remove the

1

⁄

8

” npT pipe plug

on the driver’s side of the intake manifold

as shown in Figure 3. install the

1

⁄

8

” npT male x

1

⁄

8

” compression tube adapter at this location. use

Teflon tape or sealant on the pipe thread end of

the adapter fitting.

install one end of the

1

⁄

8

” diameter plastic

tube provided in the nut and ferrule adapter

fitting and tighten the nut. check that the plastic

tube cannot be pulled out of the ferrule, but do not

over-tighten the nut.

install the boost gauge in the gauge panel

using the clamps and thumb nuts provided.

install the

1

⁄

8

” npT female x

1

⁄

8

” compression tube

adapter fitting onto the connection at the back of

the gauge. use Teflon tape or sealant on the male

threads of the gauge nipple. use sealant sparingly,

and do not allow any sealant to cover the small

pin-sized hole in the end of the gauge nipple.

route the plastic tube along one framerail

of the coach. Find an opening in the forward

bulkhead to route the tube into the driver’s

compartment. it may be necessary to drill a

3

⁄

8

”

hole. route the tube to the gauge then cut the

tube to length. insert the tube into the nut and

ferrule on the adapter fitting at the gauge, then

tighten the nut against the tube and ferrule. Do

not overtighten.

uncoil the pyrometer 4-pin connector gauge

harness. as a precaution to improper gauge

function, re-crimp the ring terminals on the ends of

the wires. connect the ring terminals to the probe

with the supplied screws. attach the YellOW & red

ring terminals from the pyrometer 4-pin connector

gauge harness to the Yellow & red probe ring

terminals, respectively.

The wires are different lengths and color

coded to prevent cross connecting. Make

sure that the screws are tight. slide the heat shrink

tubing over the connections and apply heat to the

tubing with a heat gun or other heat source.

route the gauge harness along the same

path as the boost hose. coil any excess

length and secure it with tie wraps. DO NOT

cut the harness to shorten it. The pyrometer

is calibrated to operate with the predetermined

length provided.

29.

30.

31.

32.

23.

24.

25.

26.

27.

28.

Figure 3

6

p.n. 96385