Milton CAT D6T User Manual

Page 9

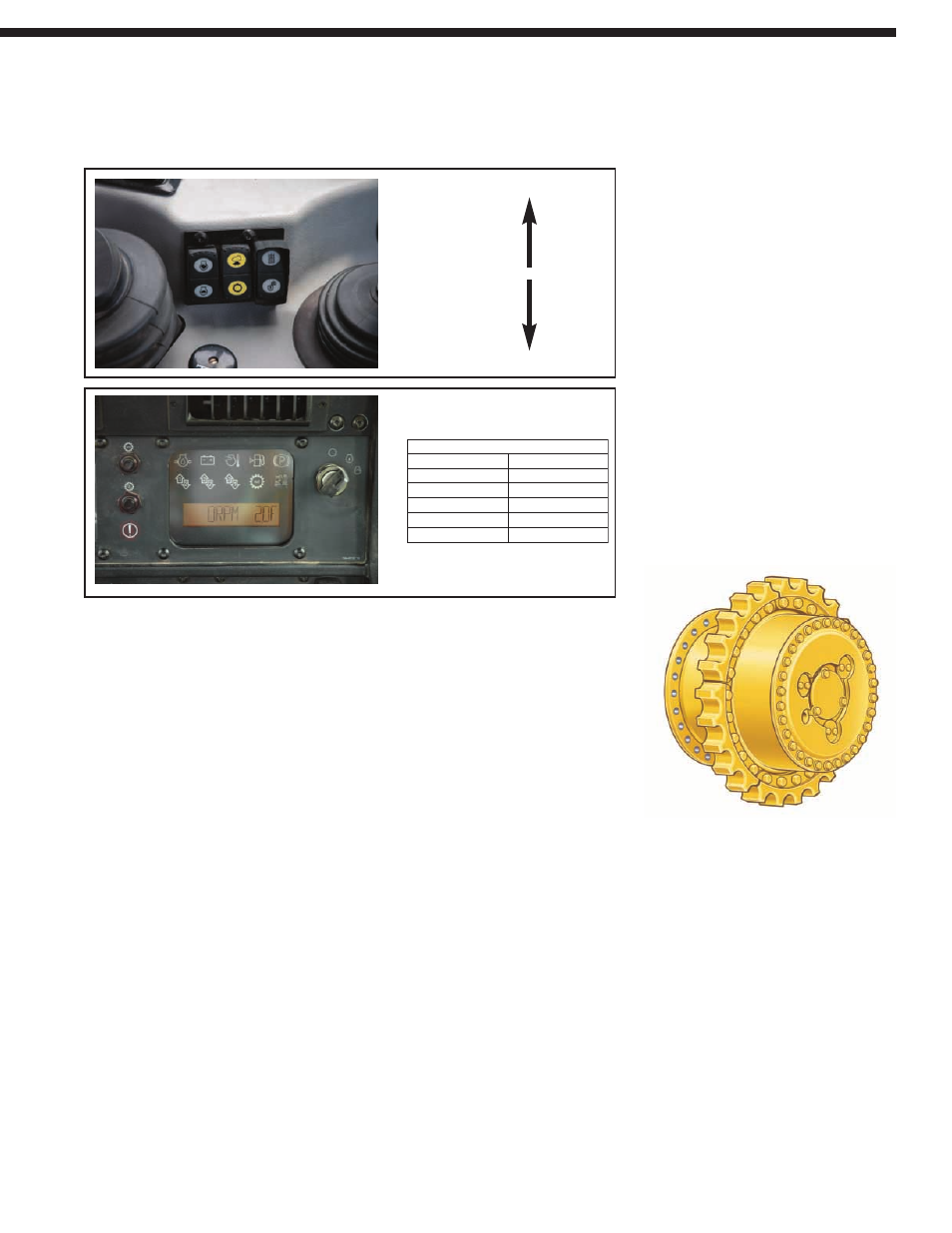

Multi Velocity Program (MVP).

The Multi Velocity Program (MVP) is an

innovative machine control system that

allows the operator to choose from five

different speed ranges in Forward and

Reverse, providing the operator with

the flexibility to match machine speed

to a variety of applications and ground

conditions. This exclusive solution allows

the operator to maximize production,

minimize fuel consumption,and lower

overall machine operating costs.

MVP provides the operator with

five speed ranges in both Forward and

Reverse. The engine speed in each speed

range has been optimized to provide the

best performance, fuel economy, and

drawbar pull. The operator retains the

ability to operate the machine in either

the 3 speed or 5 speed mode.

Operating Efficiency and Drive Line

Reliability. The D6T torque divider

attains the best combination of operating

efficiency and drive line reliability.

It acts as a hydrodynamic component

between the engine and transmission

to reduce dozing shock loads to the

transmission and final drives.

Planetary Power Shift Transmission.

The D6T planetary power shift

transmission utilizes large diameter,

high capacity, oil-cooled clutches.

These clutches provide higher torque

capacity and increased service life.

The planetary power shift transmission

offers several key features and benefits,

including:

•

Electronically controlled modulation

system that allows fast, smooth

speed and direction changes

•

Modular transmission and

differential slide into rear case for

servicing ease, even when a ripper

is installed

Differential Steering System.

Differential steering maintains power

to both tracks while turning. The tractor

turns when one track speeds up and the

other slows down an equal amount.

The operator can steer and control the

transmission simultaneously, which can

reduce cycle times in some applications.

The differential steering tiller bar has

touch shift buttons for upshifts and

downshifts. Low tiller bar efforts assure

operator comfort during long shifts.

Large blade loads can be maneuvered

around buildings, bridge abutments, trees

or other obstacles. Steering modulation

is also optimized for precise control in

these applications. Greater load capacity,

power and speed control are possible

in soft underfoot conditions on steep

slopes because both tracks are powered

during turns.

Elevated Final Drive. Elevated final

drives are isolated from ground and

work tool-induced impact loads for

extended power train life. The modular

design ensures quick and easy service

when required.

Load Compensating Shifting. With load

compensating shifting, clutch engagement

timing automatically adjusts according

to the load factor. This allows improved

tractor performance and operator

comfort during speed changes and

reduces the amount of energy dissipated

through the clutches to help extend

transmission component life.

9

3 Speed

5 Speed

DISPLAY

5 Speed

3 Speed

1.5

1

2.0

2.5

2

3.0

3.5

3