Milton CAT D6T User Manual

Page 7

ADEM™ A4 Engine Controller. The air-

cooled ADEM A4 controller is the brain

of the engine and contains the engine’s

control software. It regulates fuel

delivery, airflow and other engine

functions. In addition, it directs the

HEUI injectors to deliver multiple

injections of fuel during the engine’s

compression stroke.

Fuel Delivery. Multiple injection fuel

delivery involves a high degree of

precision. Precisely controlling the

combustion cycle lowers combustion

chamber temperatures, which lowers

emissions and optimizes fuel economy.

This translates into more work output

per unit of fuel.

HEUI™ Fuel System. The HEUI fuel

system is highly evolved, with a proven

record of reliability. HEUI uses the

technical advancement of an electronic

control system with the flexibility of

hydraulically controlled unit fuel

injection. The system excels in its

ability to control injection pressure over

the entire engine operating speed range.

These features allow the C9 to have

complete control over injection timing,

duration, and pressure.

Air-to-Air Aftercooler. The air-to-air

aftercooler (ATAAC) brings cool air

to the engine which increases life and

lowers emissions. In addition, the

ATAAC, together with the tight tolerance

combustion chamber components,

maximizes fuel efficiency.

Wastegate Turbocharger. The wastegate

allows high-volume exhaust to be

routed around the turbocharger to the

exhaust piping to prevent wheel spin

overspeed at high rpm but low load

conditions.

Service. The new C9 engine offers

easier maintenance and repair through

monitoring key functions and logging

critical indicators. Electronic diagnostic

access is possible with a single tool,

the Cat Electronic Technician.

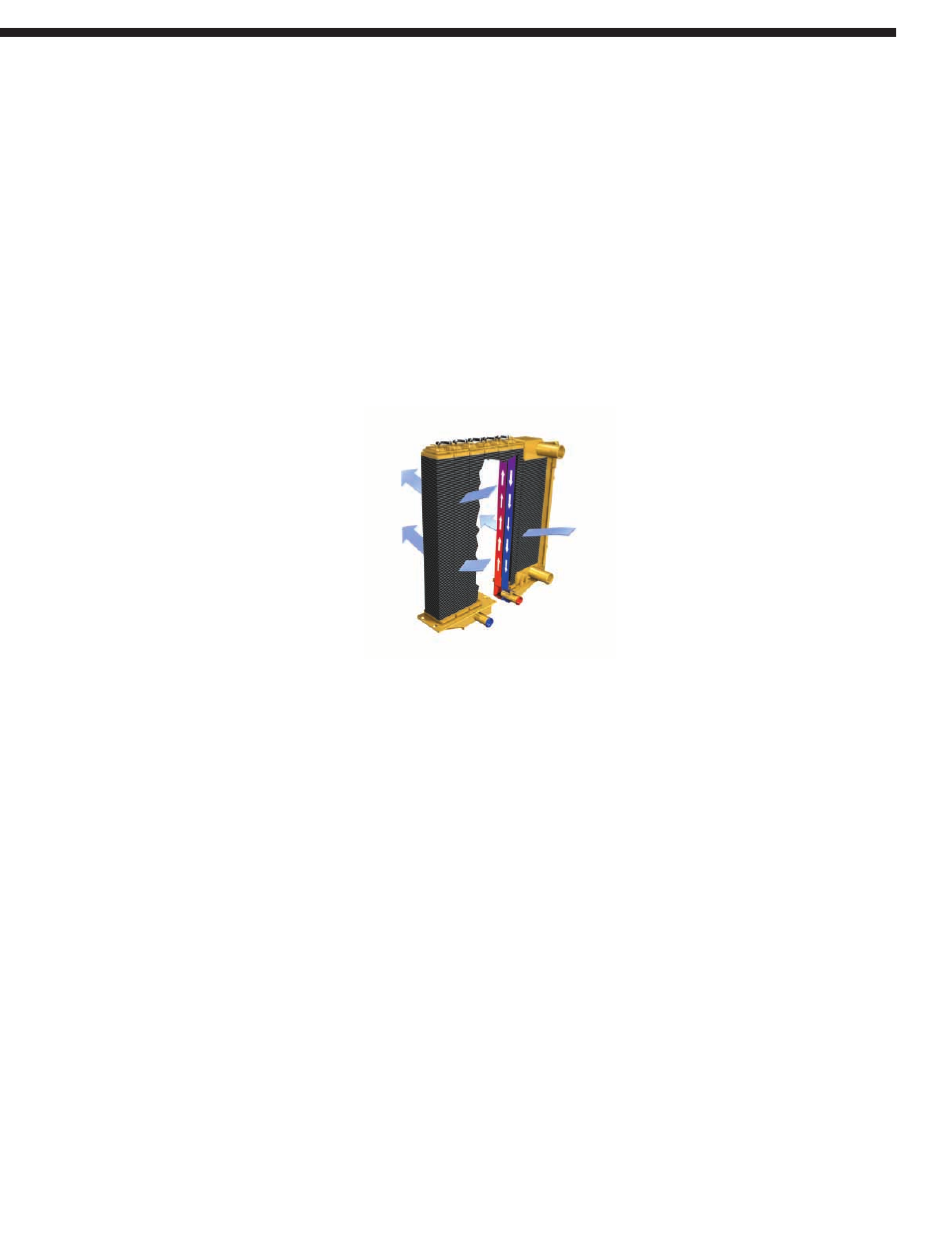

Next Generation Modular Radiator

(NGMR). Improves cooling capabilities

by using a parallel flow system with

six cores. Serviceability is improved

with NGMR since there is no top tank

to remove.

Serviceability. This modular core

design permits removal of a single core

without removing the entire radiator so

repair costs and downtime are reduced.

The top tank, side channels and one

sealing surface makes AMOCS more

reliable and easier to service. A site

gauge allows for quick service checks.

Leak Protection. To reduce the potential

for coolant leaks, brass tubes are welded

to a large, thick header to improve the

strength of the tube-to-header joint.

In conditions where abrasive materials

can be airborne, the attachment sand

blast grid should be used to prevent

core damage.

Sand Blast Grid. In an application

where airborne debris is prevalent,

radiator core protection is a concern.

To extend radiator life in harsh

applications, a sand blast grid is

available as an option to deflect the

damaging debris the engine fan propels

at the radiator.

Demand Fan Option. Based primarily

on ambient air temperature, the optional

demand fan can improve productivity

up to three percent and reduce fuel

consumption up to four percent since

the demand fan will only run at a speed

needed to meet the cooling requirements

of the machine. As cooling requirements

increase above 24° C (75° F), the demand

fan performance converges towards

that of the standard fan so lesser benefit

is achieved.

7