Milton CAT D6T User Manual

Page 5

Cab. An isolation-mounted, pressurized

cab reduces noise and vibration for

operator comfort. The cab is pre-wired

for a 12-volt or 24-volt radio, equipped

with two speakers, an antenna and a

radio mount recessed in the headliner.

Clear Working View. The operator has an

excellent view to the blade and rear of

the machine for maximum productivity.

The tapered hood, notched fuel tank and

narrow single-shank ripper carriage

give the operator a clear line of sight to

the front and rear work areas. The large

single-pane windows offer excellent

viewing to the sides and blade. The low

rear window lets the operator see the

ripper tip.

Cat Comfort Series Seat. The Cat

Comfort Series seat has a thick,

contoured cushion, rolled down front

edge and is adjustable eight-ways for

optimal support and comfort. Seat side

bolsters restrain side-to-side movement

when working on steep grades or side

slopes. The seat and suspension are

designed for 10,000-hour life.

Adjustable Armrests. Standard, adjustable

armrests provide additional comfort

for the operator. Adjustment can be

performed without the use of any tools.

In-Dash Instrument Cluster.

The instrument panel, with easy-to-read

gauges and warning lamps, keeps the

operator aware of all system information.

All gauges and readouts are easily

visible in direct sunlight.

Cat Monitoring System Display.

The dash mounted instrument

cluster provides on-the-go operating

information and gives the operator

and service technician insight into the

machine’s operation and maintenance

needs. The Caterpillar Monitoring

System includes:

•

Fuel level gauge

•

Hydraulic oil temperature gauge

•

Engine coolant temperature gauge

•

Power train oil temperature gauge

•

Engine oil pressure indicator

•

Digital readout

•

Transmission gear indicator

Heating and Air Conditioning.

Conveniently located air circulation

vents evenly distribute airflow within

the cab. Controls are easily accessible

from the operator seat.

Power Converter. The D6T features a

10-amp, 12-volt power converter for

the convenient use of radios, wireless

phones and laptop computers.

Work Tool Lock-Out Switch.

Redesigned from a mechanical rotary

switch to an electronic rocker switch,

the work tool lock-out valve prevents

inadvertent operation of the hydraulic

work tool attachments.

Throttle Rocker Switch. With the touch

of a finger, the rocker switch activates

high or low idle. A decelerator pedal

gives the operator full control of engine

speed when the rocker switch is in the

high idle position. Engine speed can

be set between high and low idle by

simultaneously using the decelerator

pedal and holding the Rabbit side of

the throttle switch in for three seconds.

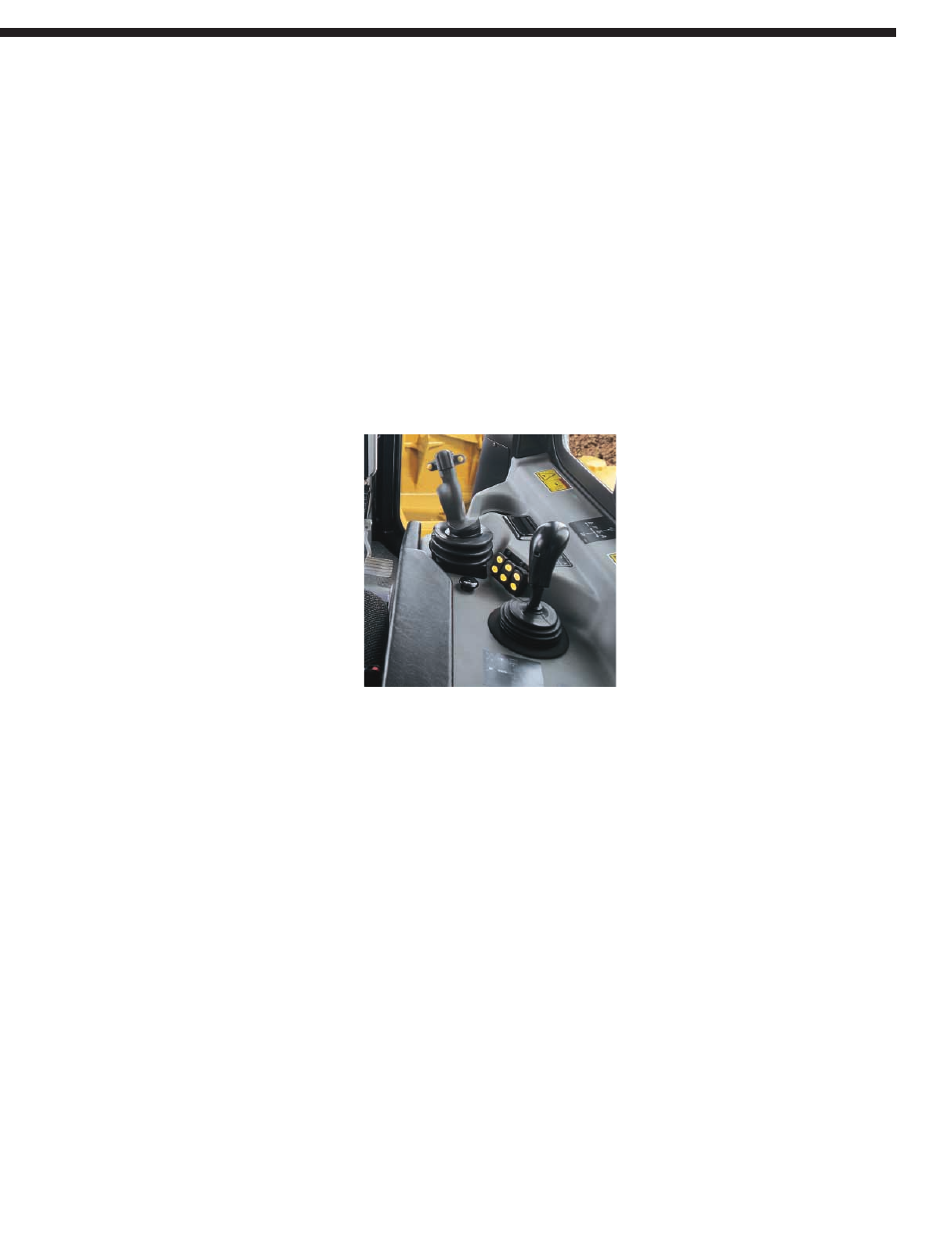

Steering and Transmission Control.

Differential steering controls the

direction and degree of turns, forward-

reverse shifting and gear selection in a

single control handle which enhances

operator comfort. Touch shift buttons

on the steering control shifts the

electronically controlled powershift

transmission. The tiller allows the

operator to work precisely in close

areas around structures, grade stakes

and other machines with the finest

modulation in the industry.

Auto-Shift/Auto-Kickdown. Auto-shift

allows the operator to pre-select a

forward and reverse gear for easy,

efficient directional changes. Auto-shift

settings include first forward to second

reverse, second forward to second

reverse, and second forward to first

reverse. Auto-kickdown allows the

transmission to automatically

downshift when significant load

increases are detected.

Dozer Control Lever. The D6T features

ergonomically designed dozer controls

with low-effort, pilot-operated

hydraulics for added operator comfort,

easy operation and precise work tool

control. When equipped with a VPAT

blade, the blade control allows

simultaneous six-way control of the

blade with a thumb rocker control to

adjust blade angle. The dozer control

is changed to an electro-hydraulic

control when the AccuGrade Ready

Option is installed.

Ripper Control Lever. The ripper control

with low-effort pilot-operated hydraulics

contributes to operator comfort, easy

operation and precise work tool control.

5