Serviceability – Milton CAT 777F User Manual

Page 12

Servicing Ease. Easy access to daily

service points simplifies servicing

and reduces time spent on regular

maintenance procedures. Enhanced

serviceability and extended 500-hour

service intervals are designed to increase

machine availability and productivity.

Engine-overhaul costs are also reduced

up to 25 percent.

Maintenance Platform. Easy stairway

access to engine, air filters, steering

hydraulic tank and radiator.

Ground-Level Access. Allows convenient

servicing to tanks, filters, drains, battery

disconnect and engine shutdown.

Engine Prelube. Engine prelubrication

provides engine oil pressure prior to

engine cranking. This reduces engine

dry and cold start wear, and reduces

engine component wear.

Fast Fill Service Center (optional).

Wiggins fast fill service center features

high-speed fuel and oil exchange and

clustered connections for all fluids for

fast, accurate servicing and reduced

downtime.

Oil Renewal System (ORS) (optional).

Extends oil change intervals and reduces

waste oil handling by continuously

burning oil from the engine oil pan

through normal engine operation.

New oil is continually added to

compensate for oil burned.

Scheduled Oil Sampling. S•O•S

SM

sampling valves speed sampling

and analysis reliability.

Pressure Test Points. Disconnect valves

are conveniently located throughout the

hydraulic systems for easy pressure

testing. New ECPC transmission provides

multiple pressure taps outside the

transmission.

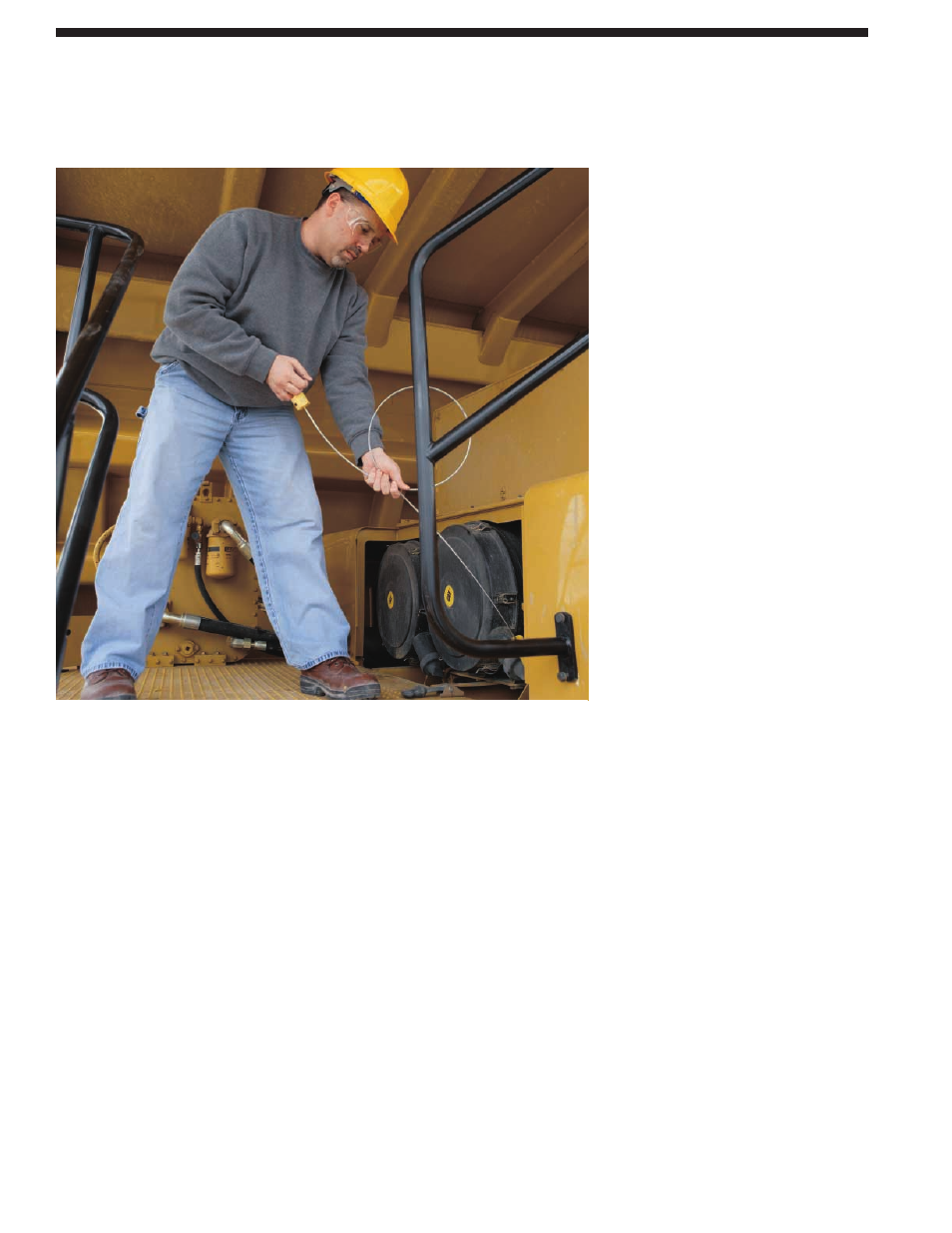

Air Filters. Radial seal air filters are

easy to change, reducing time required

for air filter maintenance.

On-Board Diagnostic Systems.

Messenger continuously checks all critical

machine functions and components, and

helps locate faults quickly for faster

repair. Electronic control system enables

quick diagnosis of engine conditions

and effective maintenance and repairs

using the Electronic Technician

(Cat ET) tool.

Lincoln’s Centro-Matic Automatic

Lubrication (optional). This advanced

lubrication system is available as a

factory installed option on the 777F.

It includes an electronically controlled

pump and adjustable injectors to dispense

a precise amount of lubricant to each

lubrication point.

Clustered Grease Fittings (optional).

Clustered grease fittings save time as

all lubrication points are mounted in

three main locations.

Next Generation Modular Radiator

(NGMR). This cooling system’s new

modular design permits removal of a

single core without removing the entire

radiator, reducing downtime and repair

costs. NGMR also offers wider fin

spacing for greater resistance to plugging

and more convenient cleaning.

QuickEvac™ System. Oil change labor

time is reduced by as much as 50 percent

with this standard on-board engine oil

evacuation and pre-lube system. It speeds

the process of evacuating the engine

sump and allows for the purging of oil

filters prior to removal, minimizing oil

spills. QuickEvac system also enhances

contamination control by ensuring

filtration of new oil on engine refill.

Reduced Maintenance Costs/Higher

Machine Availability. The C32 engine

with ACERT Technology offers 500-hour

service intervals under normal conditions.

For the 777F, commonly used engine

service points have been placed on the

right side of the engine. Feedback from

engine sensors provides data to the

electronic controller. When engine

data is out of spec, a warning is sent

to the operator.

12

Less time spent on maintenance means more time on the haul roads.

Serviceability