Thermal resistance characteristics, t, 25°c unless otherwise specified, Mechanical characteristics – C&H Technology CM100MXA-24S User Manual

Page 7: Recommended operating conditons, t, 25°c

CM100MXA-24S

NX-S Series CIB Module

(3Ø Converter + 3Ø Inverter + Brake)

100 Amperes/1200 Volts

Powerex, Inc., 173 Pavilion Lane, Youngwood, Pennsylvania 15697 (724) 925-7272 www.pwrx.com

6

05/11 Rev. 2

Thermal Resistance Characteristics,

T

j

= 25°C unless otherwise specified

Thermal Resistance, Junction to Case

*2

R

th(j-c)

Q

Per Inverter IGBT, per 1/6 Module

—

—

0.20

K/W

Thermal Resistance, Junction to Case

*2

R

th(j-c)

D

Per Inverter FWDi, per 1/6 Module

—

—

0.29

K/W

Thermal Resistance, Junction to Case

*2

R

th(j-c)

Q

Brake Part IGBT

—

—

0.35

K/W

Thermal Resistance, Junction to Case

*2

R

th(j-c)

D

Brake Part ClampDi

—

—

0.63

K/W

Thermal Resistance, Junction to Case

*2

R

th(j-c)

D

Converter Part ConvDi, per 1/6 Module

—

—

0.24

K/W

Contact Thermal Resistance,

R

th(c-s)

Thermal Grease Applied,

—

0.015

— K/W

Case to Heatsink

*2

per 1 Module

*7

Mechanical Characteristics

Mounting Torque M

s

Mounting to Heatsink, M5 Screw

22 27 31 in-lb

Weight

m

— 300 — Grams

Creepage Distance

d

s

Terminal to Terminal

6.47

—

—

mm

Terminal to Baseplate

14.27

— — mm

Clearance

d

a

Terminal to Terminal

6.47

—

—

mm

Terminal to Baseplate

12.33

— — mm

Flatness of Baseplate

e

c

On Centerline X, Y

*8

±0 — ±100 µm

Recommended Operating Conditons,

T

a

= 25°C

(DC) Supply Voltage

V

CC

Applied Across P-N/P1-N1 Terminals

—

600

850

Volts

Gate (-Emitter Drive) Voltage

V

GE(on)

Applied Across GB-Es / G*P-*/ G*N-Es 13.5

15.0

16.5

Volts

(* = U, V, W) Terminals

External Gate Resistance

R

G

Inverter Part IGBT

6.2

—

62

Ω

Brake Part IGBT

13

—

130

Ω

*2 Case temperature (T

C

) and heatsink temperature (T

s

) is measured on the surface

(mounting side) of the baseplate and the heatsink side just under the chips.

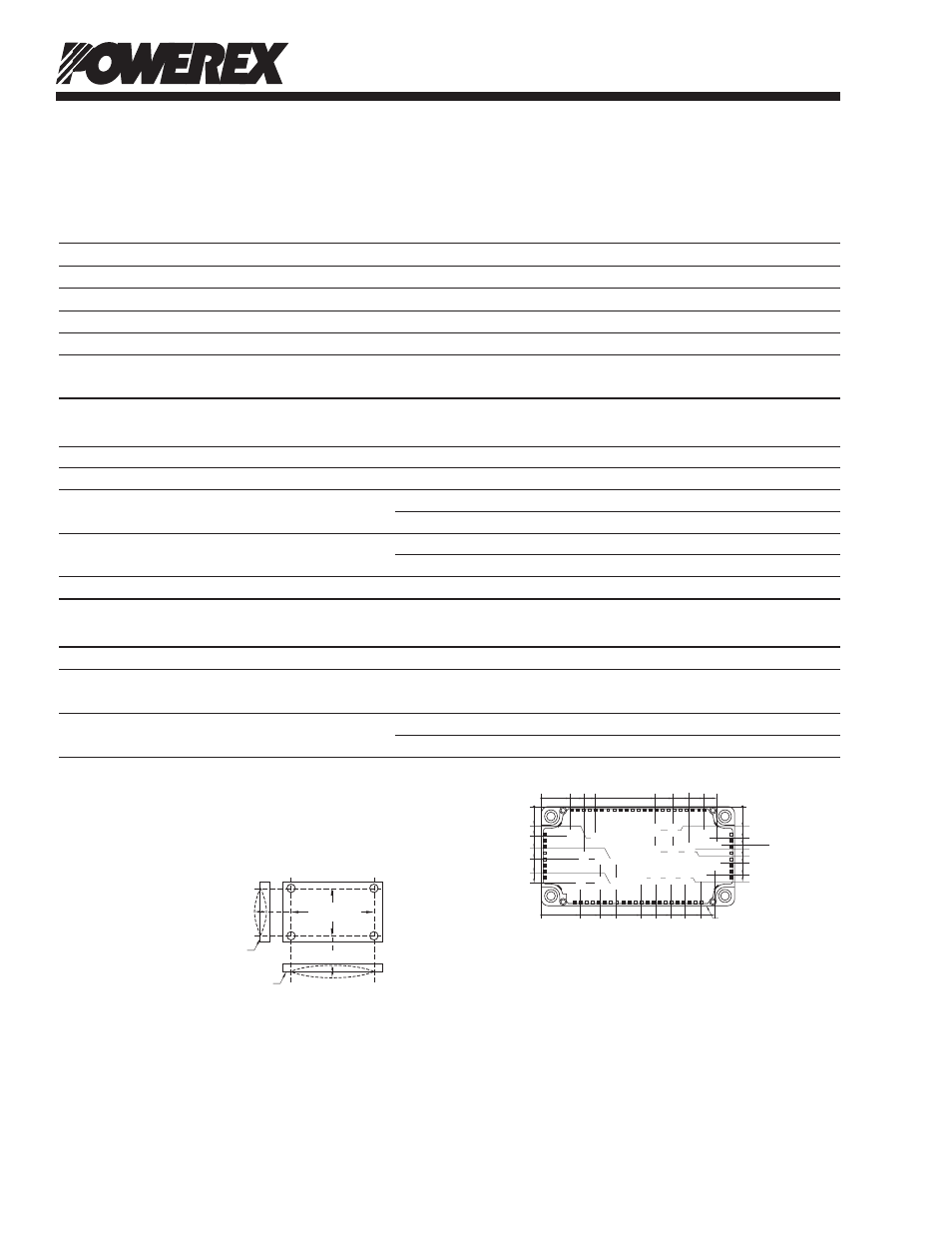

Refer to the figure to the right for chip location.

The heatsink thermal resistance should be measured just under the chips.

*7 Typical value is measured by using thermally conductive grease of λ = 0.9 [W/(m • K)].

*8 Baseplate (mounting side) flatness measurement points (X, Y) are shown in the figure below.

– :

CONC

A

VE

+ :

CONVEX

– : CONCAVE

X

Y

+ : CONVEX

MOUNTING

SIDE

MOUNTING SIDE

MOUNTING SIDE

1

2

3 4 5

6

7 8

9 10 11 12 13 14 15 16 17 18 19 20 21 22

53

54

55

56

57

58

59

60

61

30

29

28

27

26

25

24

23

52 51 50 49 48 47 46 45 44 43 42 41 40 39 38 37 36 35 34 33 32 31

0

0

17.5

20.0

18.1

31.2

32.6

47.0

48.0

15.2

LABEL SIDE

Each mark points to the center position of each chip.

Tr*P / Tr*N / TrBr (* = U/V/W): IGBT

Di*P / Di*N (* = U/V/W): FWDi

DiBr: Clamp Di

CR*P / CR*N (* = R/S/T): Conv Di

Th: NTC Thermistor

0

24.5

18.2

0

33.9

26.0

71

.8

82.9

93.0

102.3

46.8

36.4

62.9

72.1

81

.3

90.5

99.8

109.1

26.8

26.0

24.6

35.7

43.1

46.7

11

0.9

Tr

Br

Di

Br

Di

UN

Di

VN

Di

WN

Tr

UN

Tr

VN

Tr

WN

Tr

WP

Th

CR

RN

CR

SN

CR

TN

CR

RP

CR

SP

CR

TP

Di

WP

Di

VP

Tr

VP

Di

UP

Tr

UP