VEGA VEGAFLEX 83 Modbus and Levelmaster protocol Polished version User Manual

Page 20

20

4 Mounting

VEGAFLEX 83 • Modbus and Levelmaster protocol

41843-EN-130314

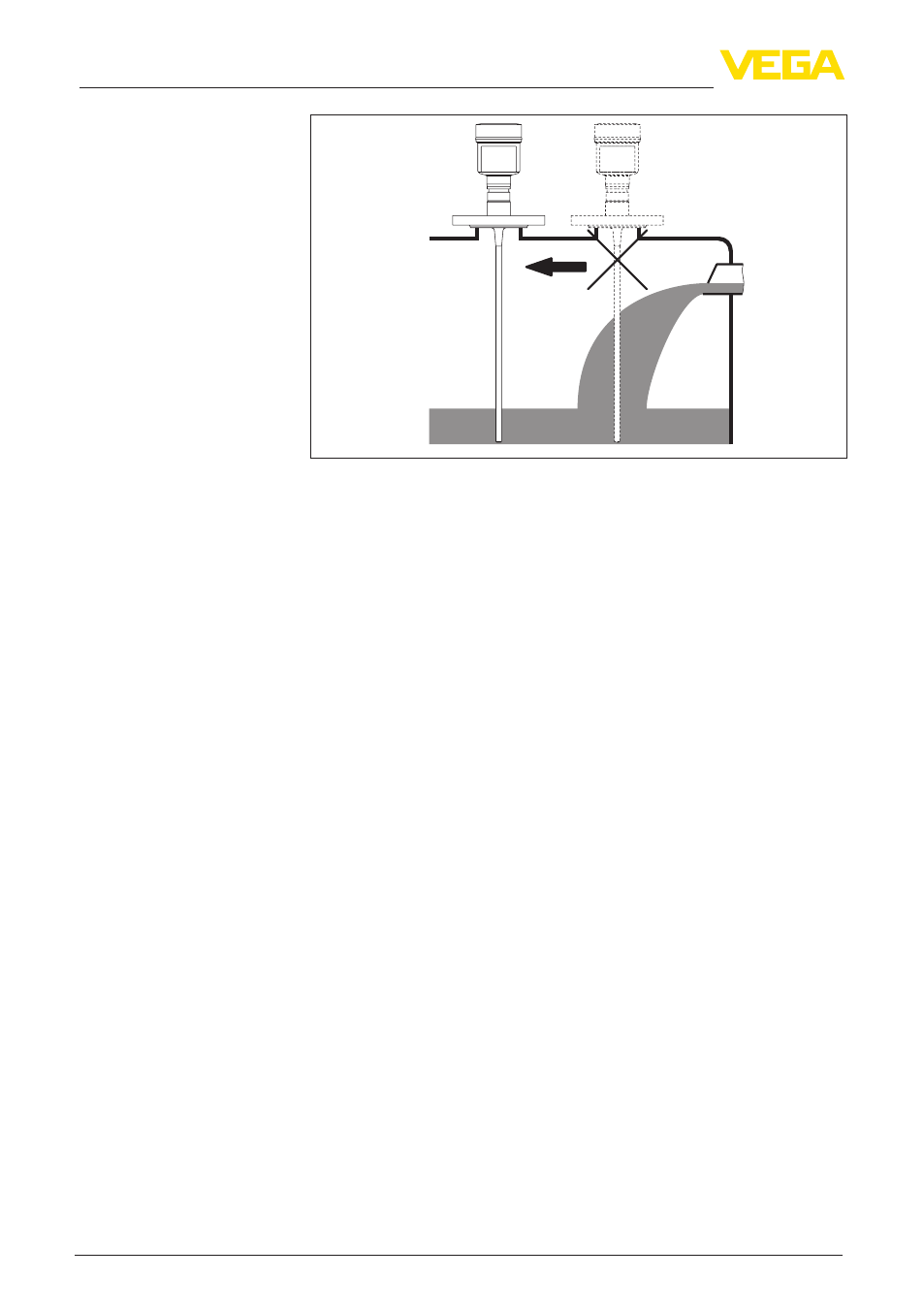

Fig. 12: Mounting of the sensor with inflowing medium

The reference plane for the measuring range of the sensors is the

sealing surface of the thread or flange.

Keep in mind that a min. distance must be maintained below the refer-

ence plane and possibly also at the end of the probe - measurement

in these areas is not possible (dead band). The length of the cable

can be used all the way to the end only when measuring conductive

products. These blocking distances for different mediums are listed

in chapter "Technical data". Keep in mind for the adjustment that the

default setting for the measuring range refers to water.

The process fitting must be sealed if there is gauge or low pressure in

the vessel. Before use, check if the seal material is resistant against

the measured product and the process temperature.

The max. permissible pressure is specified in chapter "Technical

data" or on the type label of the sensor.

For use in an autoclave, e.g. for sterilization, the VEGAFLEX 83 is

available as autoclaved version.

Hence you can separate the housing from the process fitting.

Open the slotted nut with a hook wrench and remove the housing in

an upward direction.

The side of the process fitting must be covered with a lid after the

housing is removed. Screw the enclosed lid with slotted nut onto the

instrument side of the process fitting and tighten the nut with a torque

of 20 Nm.

Make sure that no liquid or contamination penetrates into the housing

or the process side.

After autoclaving, screw the lid off again and place the housing verti-

cally on the side of the process fitting. Tighten the slotted nut with a

torque of 20 Nm.

Measuring range

Pressure

Autoclaved version