VEGA VEGAFLEX 83 4 … 20 mA_HART two-wire Rod probe - Polished version With SIL qualification User Manual

Page 19

19

4 Mounting

VEGAFLEX 83 • 4 … 20 mA/HART two-wire

44225-EN-130823

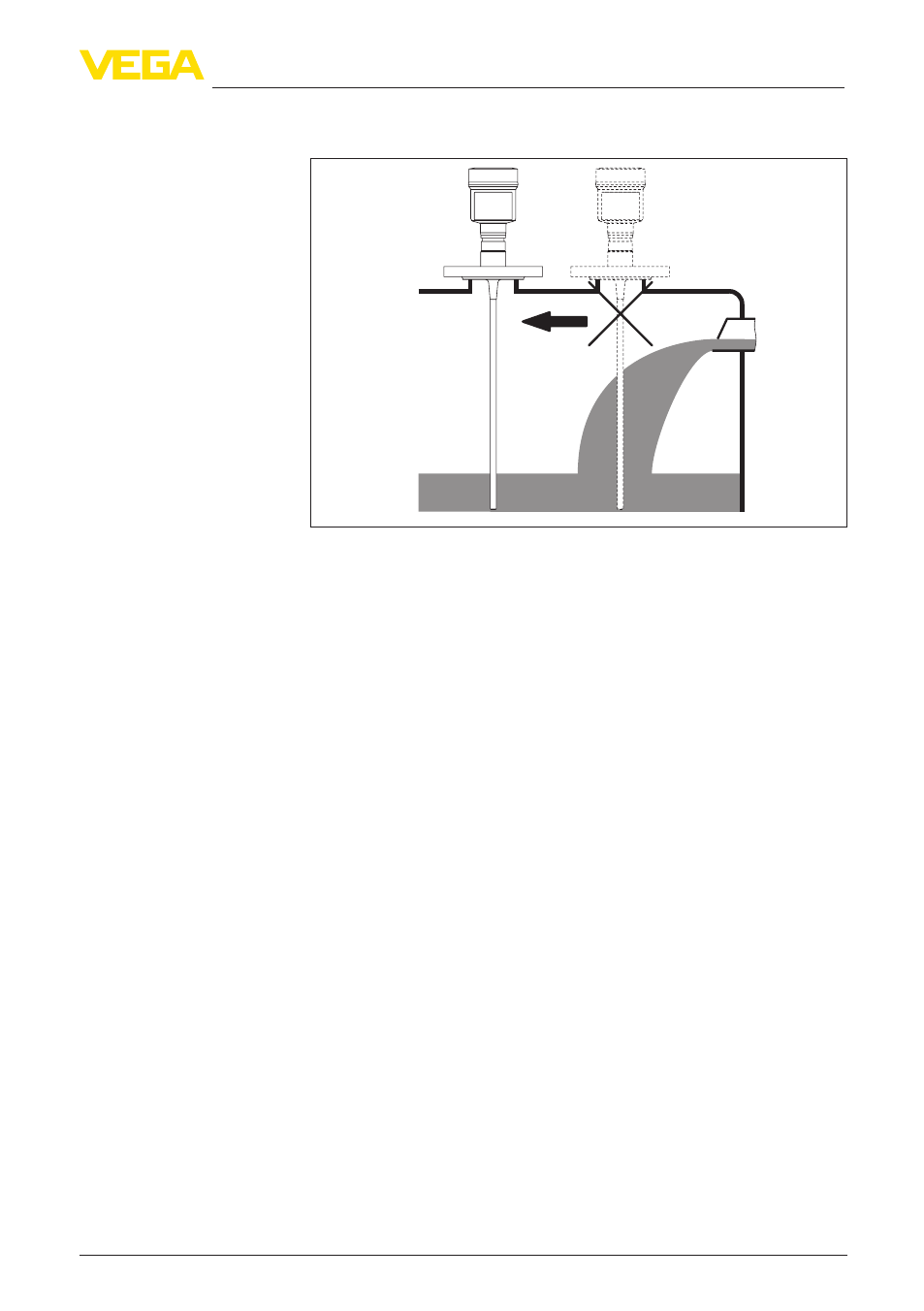

Do not mount the instruments in or above the filling stream. Make sure

that you detect the product surface, not the inflowing product.

Fig. 11: Mounting of the sensor with inflowing medium

The reference plane for the measuring range of the sensors is the

sealing surface of the thread or flange.

Keep in mind that a min. distance must be maintained below the refer-

ence plane and possibly also at the end of the probe - measurement

in these areas is not possible (dead band). The length of the cable

can be used all the way to the end only when measuring conductive

products. These blocking distances for different mediums are listed

in chapter "Technical data". Keep in mind for the adjustment that the

default setting for the measuring range refers to water.

The process fitting must be sealed if there is gauge or low pressure in

the vessel. Before use, check if the seal material is resistant against

the measured product and the process temperature.

The max. permissible pressure is specified in chapter "Technical

data" or on the type label of the sensor.

In case of difficult installation conditions, the probe can be also

mounted laterally. For this purpose, adapt the rod with rod extensions

or bow-shaped segments.

Let the probe length determine automatically by the instrument to

compensate the resulting running time changes.

The determine probe length can deviate from the actual probe length

when using bow-shaped segments.

If installations such as struts, ladders, etc. exist on the vessel wall,

then the probe should have a distance to the vessel wall of at least

300 mm (11.81 in).

You can find further information in the supplementary instructions of

the rod extension.

Inflowing medium

Measuring range

Pressure

Lateral installation