4 rectify faults – VEGA VEGAFLEX 81 Profibus PA User Manual

Page 70

70

9 Diagnostics and service

VEGAFLEX 81 • Profibus PA

44217-EN-130910

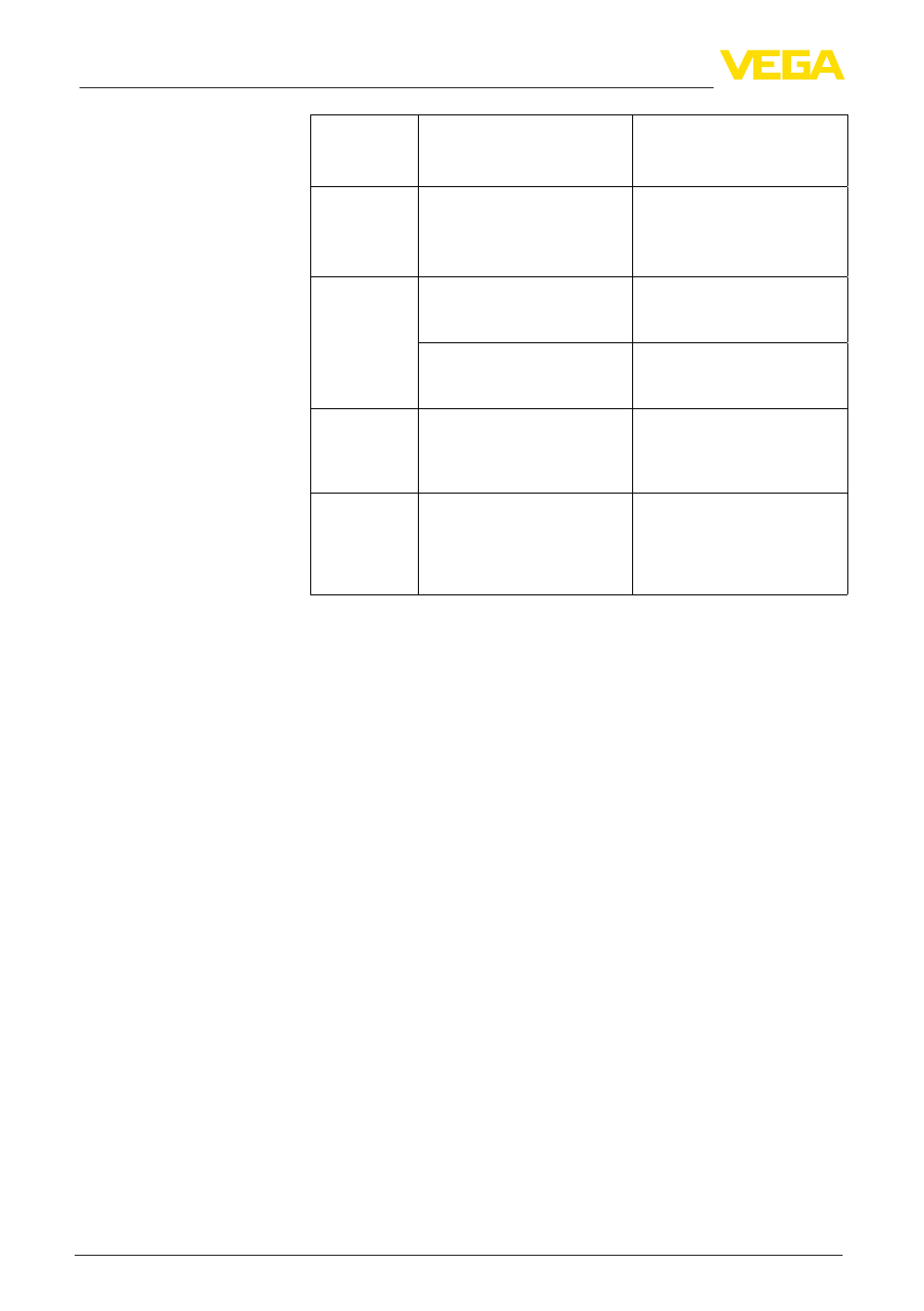

Code

Text mes-

sage

Cause

Rectification

M504

Error on an

device inter-

face

– Hardware defect

– Exchanging the electronics

– Send instrument for repair

M505

no measured

value avail-

able

– Sensor does not detect an

echo during operation

– Check and correct instal-

lation and/or parameter

adjustment

– Process component or

probe contaminated or

defective

– Clean or exchange process

component or probe

M506

Installation/

Setup error

– Error during setup

– Check and correct instal-

lation and/or parameter

adjustment

– Check probe length

M507

Error in the

instrument

settings

– Error during setup

– Error when carrying out a

reset

– False signal suppression

faulty

– Carry out reset and repeat

setup

9.4 Rectify faults

The operator of the system is responsible for taking suitable meas-

ures to rectify faults.

The first measures are:

•

Evaluation of fault messages, for example via the display and

adjustment module

•

Checking the output signal

•

Treatment of measurement errors

Further comprehensive diagnostics options offer a PC with the soft-

ware PACTware and the suitable DTM. In many cases, the reasons

can be determined in this way and faults can be rectified.

The below tables show typical examples for application-relevant

measurement errors. There are two measurement errors:

•

Constant level

•

Filling

•

Emptying

The images in column "Error pattern" show the real level with a bro-

ken line and the level displayed by the sensor as a continuous line.

Reaction when malfunc-

tions occur

Procedure for fault recti-

fication

Treatment of measure-

ment errors