VEGA VEGAFLEX 81 4 … 20 mA_HART two-wire Coax probe User Manual

Page 17

17

4 Mounting

VEGAFLEX 81 • 4 … 20 mA/HART two-wire

42279-EN-130612

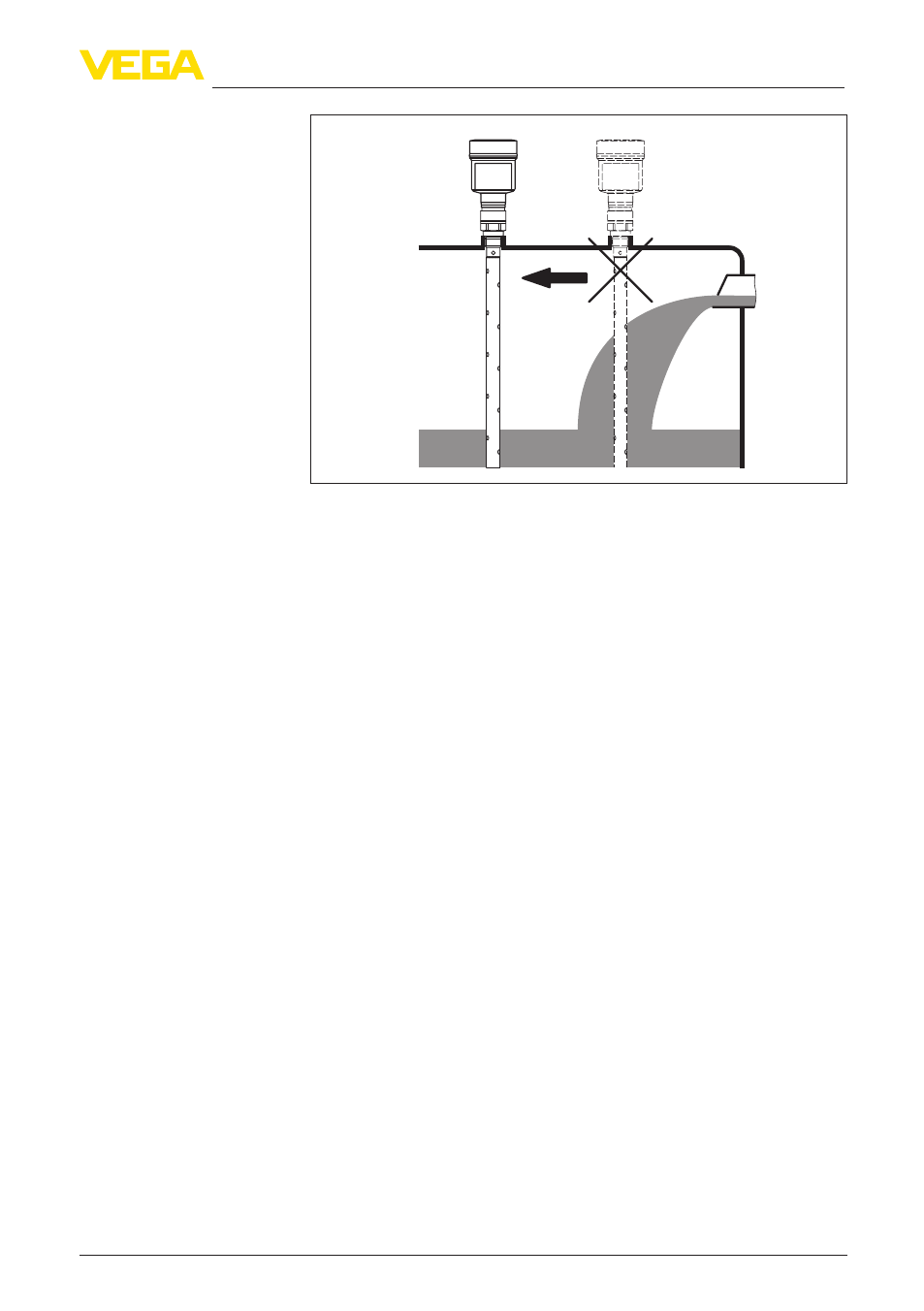

Fig. 7: Mounting of the sensor with inflowing medium

The reference plane for the measuring range of the sensors is the

sealing surface of the thread or flange.

Keep in mind that a min. distance must be maintained below the refer-

ence plane and possibly also at the end of the probe - measurement

in these areas is not possible (dead band). These dead bands are

listed in chapter "Technical data". Keep in mind for the adjustment that

the default setting for the measuring range refers to water.

The process fitting must be sealed if there is gauge or low pressure in

the vessel. Before use, check if the seal material is resistant against

the measured product and the process temperature.

The max. permissible pressure is specified in chapter "Technical

data" or on the type label of the sensor.

Vapours, superimposed gases, high pressures and temperature dif-

ferences can change the spreading speed of radar impulses.

There are two possibilities to correct these deviations.

Corrective value in the process control system

In the technical data under "Influence of superimposed gas and pres-

sure on accuracy" you can find a table with deviation values in some

typical gases or in steam.

In the control system (DCS) you can correct the measurement results

of the VEGAFLEX 81 with these values.

The prerequisite is constant temperature and pressure in the vessel.

Automatic correction via the reference distance

The VEGAFLEX 81 can be equipped optionally with a running time

correction via reference distance. The probe can carry out an auto-

matic running time correction with it.

Measuring range

Pressure

Steam boiler applications