VEGA VEGASOURCE 31 User Manual

Page 40

40

7 Maintenance and fault rectification

VEGASOURCE 31 •

38131-EN-130415

tions and comprise, apart from the source container also all other

affected parts of the process vessel.

The tightness test must be carried out immediately after an incident.

The tightness test described below is:

•

For regular test during operation

•

During a longer storage period of the source container

•

When the source container is put into operation after a longer

storage period

The tightness test (also wipe test) must be carried out by an author-

ized person or organisation by means of a tightness test facility which

is procured by an authorised organisation. Tightness test facilities

must be used according to the instructions of the manufacturer. Proto-

cols on the rest results must be kept.

If there is no other instruction available, carry the tightness test as

follows:

A

B

C

D

KLMN

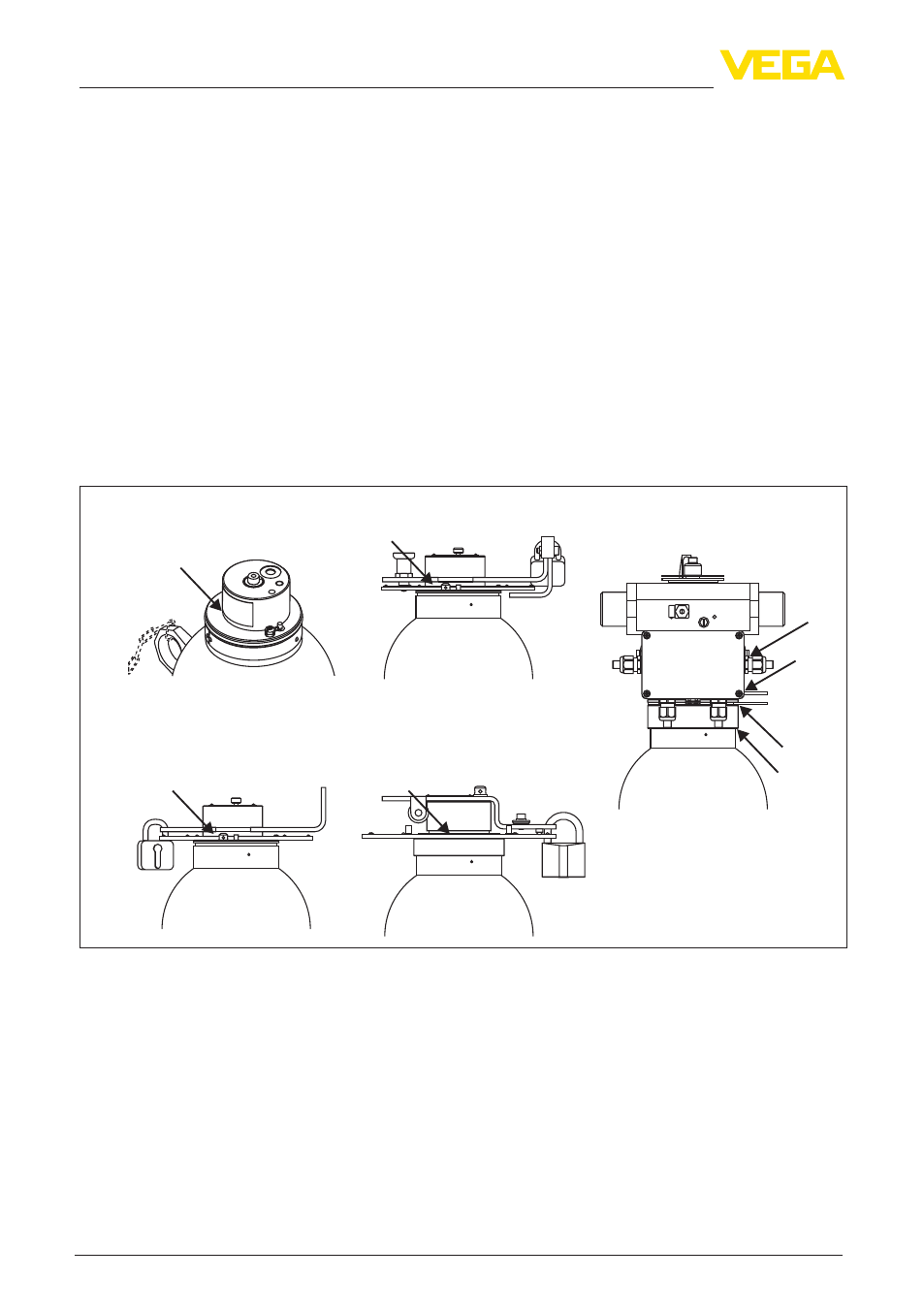

Fig. 29: Wiping surfaces for the tightness test

1. Take wipe samples at least from the following positions:

Version A B C D - along the groove between source insert and

housing

Version K L M N - along the thread of the proximity switch and the

three circular grooves on the cylinder housing

With manually operated source holders, the thighness test can be

carried out when the source holder is in position ON or OFF.

With source holders with pneumatic switching facility, the switch

must be fixed with the lock in position OFF before starting the

tightness test.

Sequence of the tight-

ness test