VEGA VEGADIF 65 Profibus PA User Manual

Page 11

11

3 Product description

VEGADIF 65 • Profibus PA

36129-EN-130417

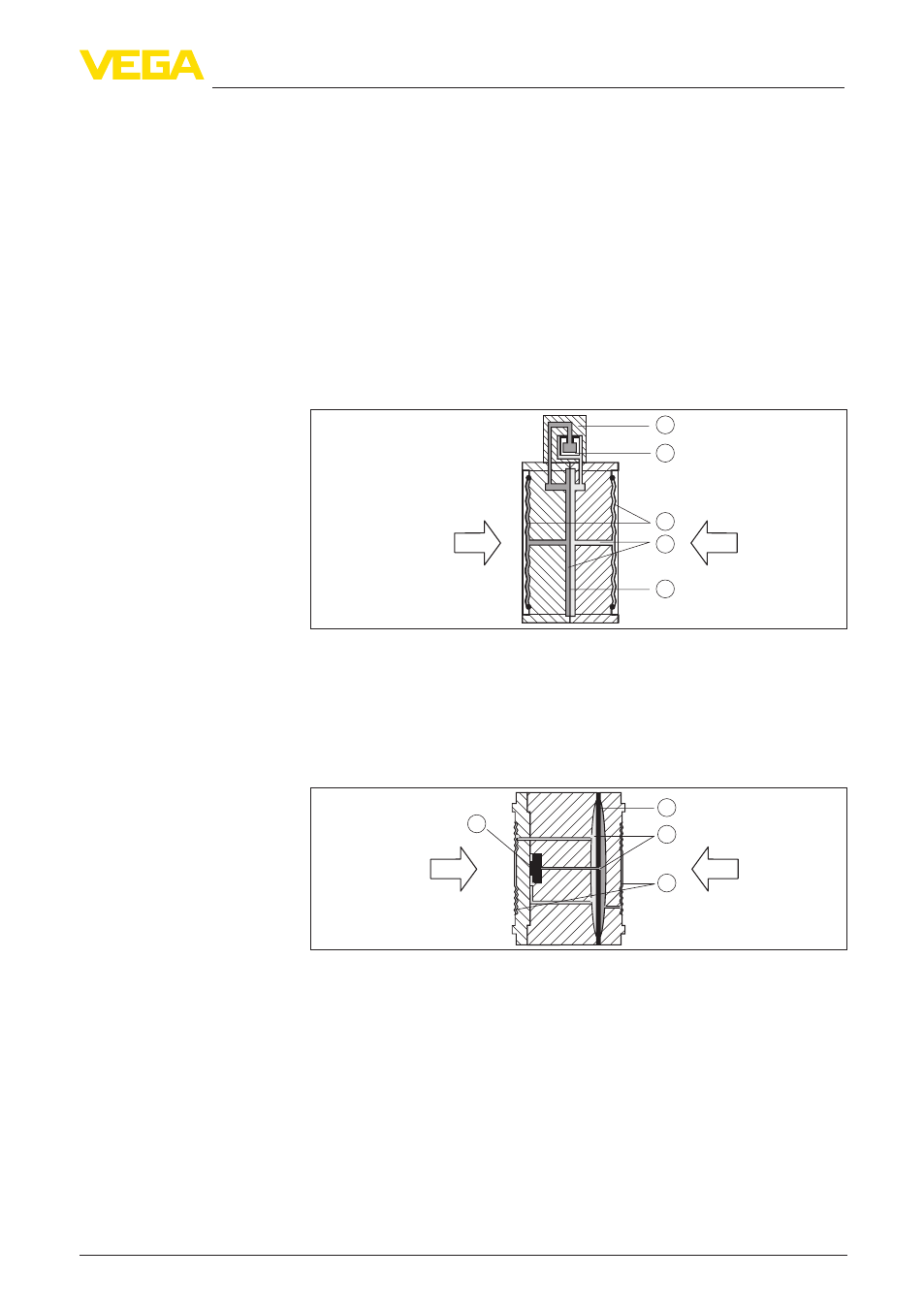

A metallic measuring cell is used as sensor element. The process

pressures are transmitted via the separating diaphragms and filling

oils to a resistance measuring bridge (semi-conductor technology).

The difference between the acting pressures generates a change in

the bridge voltage. This change is measured, further processed and

converted into a corresponding output signal.

The markings "+" and "-" on the process component in chapter

"Mounting and connection instructions" must therefore be noted when

connecting to the process. The pressure acting on "+" goes positive,

the pressure acting on "-" goes negative into the calculation of the

pressure difference.

The configuration of the measuring cells differs depending on the

measuring range:

1

2

3

4

5

1

p

2

p

Fig. 8: Metallic measuring cell 10 mbar and 30 mbar - p

1

and p

2

process pres-

sures

1 Measuring element

2 Silicone diaphragm

3 Separating diaphragm

4 Filling oil

5 Integrated overvoltage arrester

1

p

2

p

1

2

3

4

Fig. 9: Metallic measuring cell from 100 mbar - p

1

and p

2

process pressures

1 Measuring element

2 Overload diaphragm/Middle diaphragm

3 Filling oil

4 Separating diaphragm

Power supply via the Profibus DP/PA segment coupler or VEGALOG

571 EP cards. A two-wire cable according to Profibus specification

serves as carrier of both power and digital data transmission for

multiple sensors. The instrument profile of VEGADIF 65 corresponds

to profile specification version 3.0.

Functional principle

Power supply and bus

communication