3 function chart – VEGA VEGASWING 61 - two-wire User Manual

Page 18

18

6 Setup

VEGASWING 61 • - two-wire

29227-EN-130409

Control lamp (LED) for indication of the switching condition

•

green = tuning fork uncovered

•

red = tuning fork covered

•

off = failure

With this DIL switch (2) you can set the switching point to liquids

having a density between 0.5 and 0.7 g/cm³ (0.018 and 0.025 lbs/

in³). With the basic setting, liquids with a density of > 0.7 g/cm³ (0.025

lbs/in³) can be detected. In liquids with lower density, you must set

the switch to > 0.5 g/cm³ (0.018 lbs/in³). The specifications for the

position of the switching point relate to water - density value 1 g/cm³

(0.036 lbs/in³). In products with a different density, the switching point

will shift in the direction of the housing or tuning fork end depending

on the density and type of installation.

Note:

Keep in mind that foams with a density > 0.45 g/cm³ (0.016 lbs/in³)

are detected by the sensor. This can cause faulty switchings particu-

lary when used as dry run protection system.

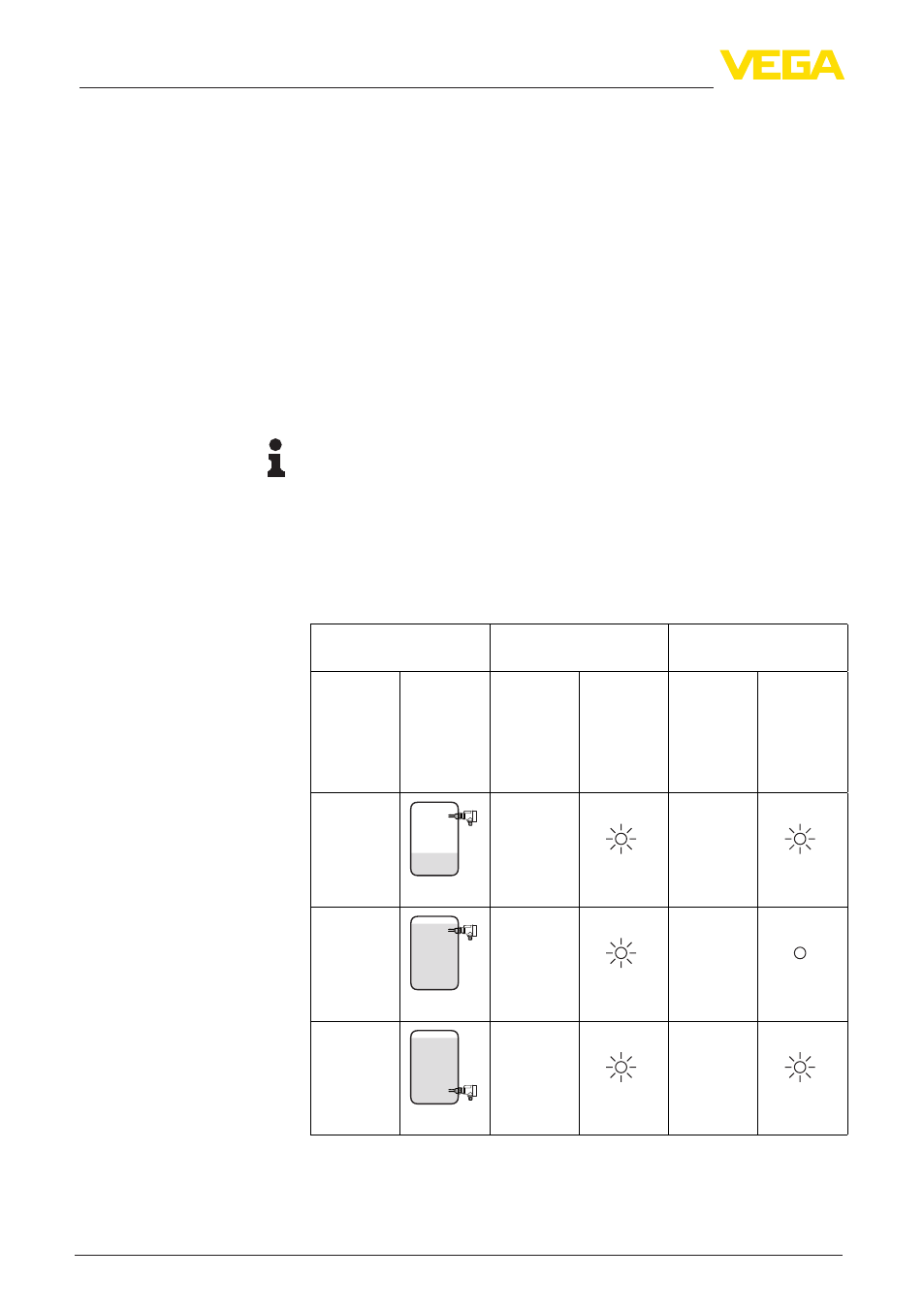

6.3 Function chart

The following chart provides an overview of the switching conditions

depending on the set mode and the level.

Sensor

Signal conditioning in-

strument

Mode on

the signal

condi-

tioning

instrument

Level

Signal

current -

Sensor

Signal

lamp -

sensor

Analogue

- input

control

1)

Signal

lamp -

signal

condi-

tioning

instrument

Mode A

Overflow

protection

approx.

8 mA

Green

> 3.8 mA

< 11.5 mA

Mode A

Overflow

protection

approx.

16 mA

Red

> 12.5 mA

< 21.6 mA

Mode B

Dry run

protection

approx.

16 mA

Red

> 12.5 mA

< 21.6 mA

Signal lamp (1)

Sensitivity adjustment (2)

1)

Electronics directly evaluated via the analogue input of a control system

(without signal conditioning instrument)