2 application features, Continuous and reliable – VEGA VEGAPULS 56 Profibus PA User Manual

Page 6

6

VEGAPULS 56 Profibus PA

1.2 Application features

Applications

• level measurement of liquids, limited use in

solids

• measurement also in vacuum

• all slightly conductive materials and all

substances with a dielectric constant

ε

r

> 2.0 can be measured

• measuring ranges 0 … 20 m

Two-wire technology

• power supply and output signal on one

two-wire cable

• digital output signal

Rugged and abrasionproof

• non-contact

• high resistance materials

Exact and reliable

• resolution 1 mm

• unaffected by noise, vapours, dusts, gas

compositions and inert gas stratification

• unaffected by varying density and tem-

perature of the medium

• measurement of pressures up to 64 bar

and product temperatures up to 350°C

Communicative

• individual wiring, with 15 sensors on one

two-wire cable (digital output signal)

• integrated measured value display

• optional display module up to 25 m sepa-

rate from the sensor

• connection to all bus systems: Interbus S,

Modbus, Siemens 3964R, Profibus DP,

Profibus FMS, ASCII

• adjustment from PLC level

Ex approvals

• CENELEC, FM, ABS, LRS, GL, LR, ATEX,

PTB, FCC

Product description

The signal reflection grows stronger with

increasing product conductivity or dielectric

constant. Hence virtually all products can be

measured.

With standard flanges of DN 50 to DN 250,

ANSI 2“ to ANSI 10“ the sensor antenna sys-

tems can be adapted to various products

and measuring environments. The high-

quality materials of the sensors can also

withstand extreme chemical and physical

conditions. The sensors deliver stable, repro-

ducible analogue or digital level signals with

reliability and precision, and have a long

useful life.

Continuous and reliable

Unaffected by temperature, pressure and

individual gas atmospheres, VEGAPULS

radar sensors are ideal for non-contact, fast

and accurate level measurement of various

products.

VEGAPULS series 56 sensors enable level

measurement with radar in systems where it

was previously not used due to high costs.

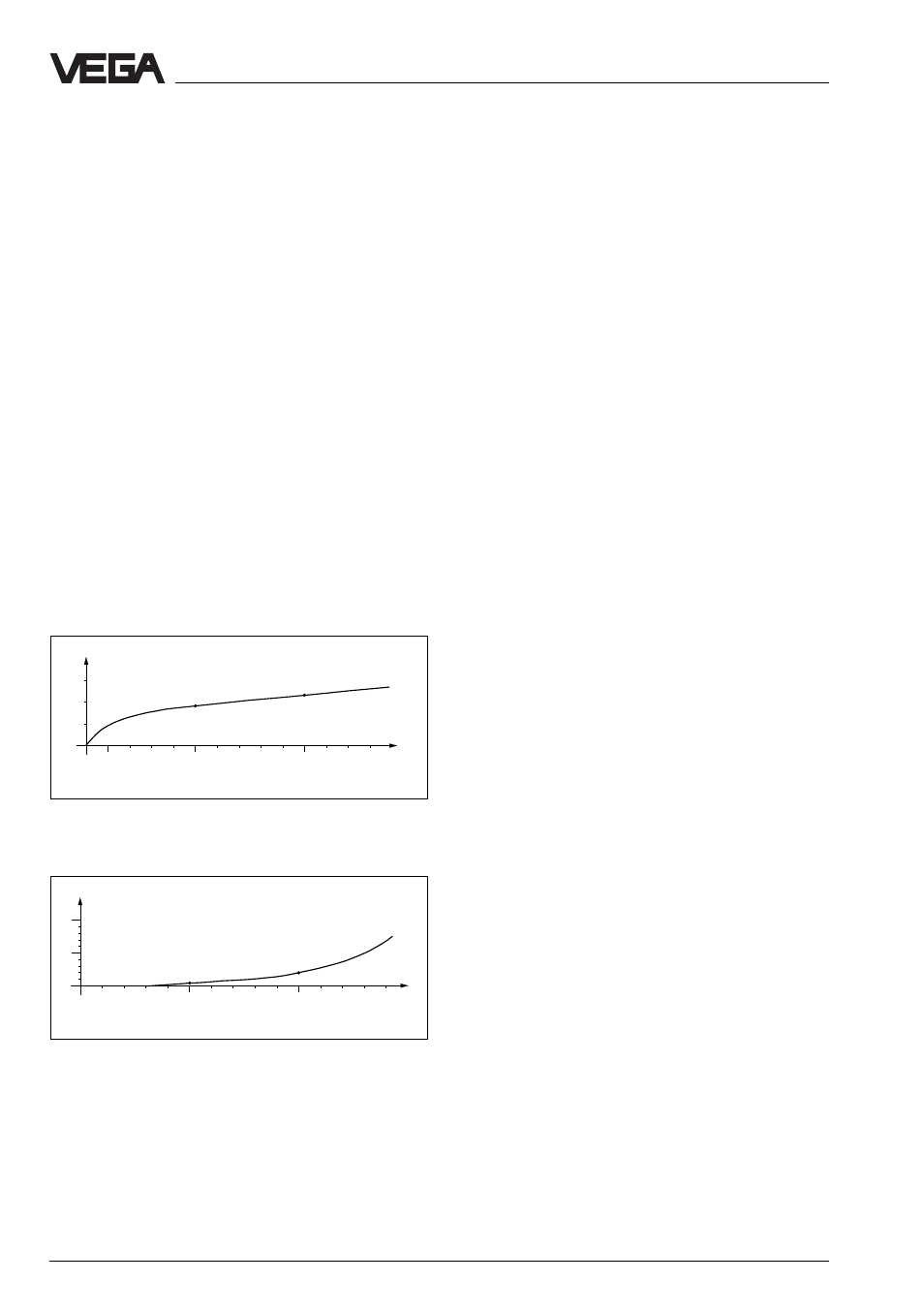

Temperature influence: Temperature error absolutely

zero (e.g. at 500°C 0.018 %)

Pressure influence: Error with pressure increase very

low (e.g. at 50 bar 1.44 %)

100

500

1000

1300 ˚C

0

0

0,01

0,02

0,03

%

0,018 %

0,023 %

10

0

0

5

%

0,8 %

3 %

10

50

20

30

40

60

100

70

80

90

110

120

130

140

bar