Use of guide tubes, Seals on tube connections and tube ex- tensions – VEGA VEGAPULS 51K…54K 4 … 20 mA; HART compact sensor User Manual

Page 17

VEGAPULS 51K … 54K

17

21750-EN-031222

Mounting and installation

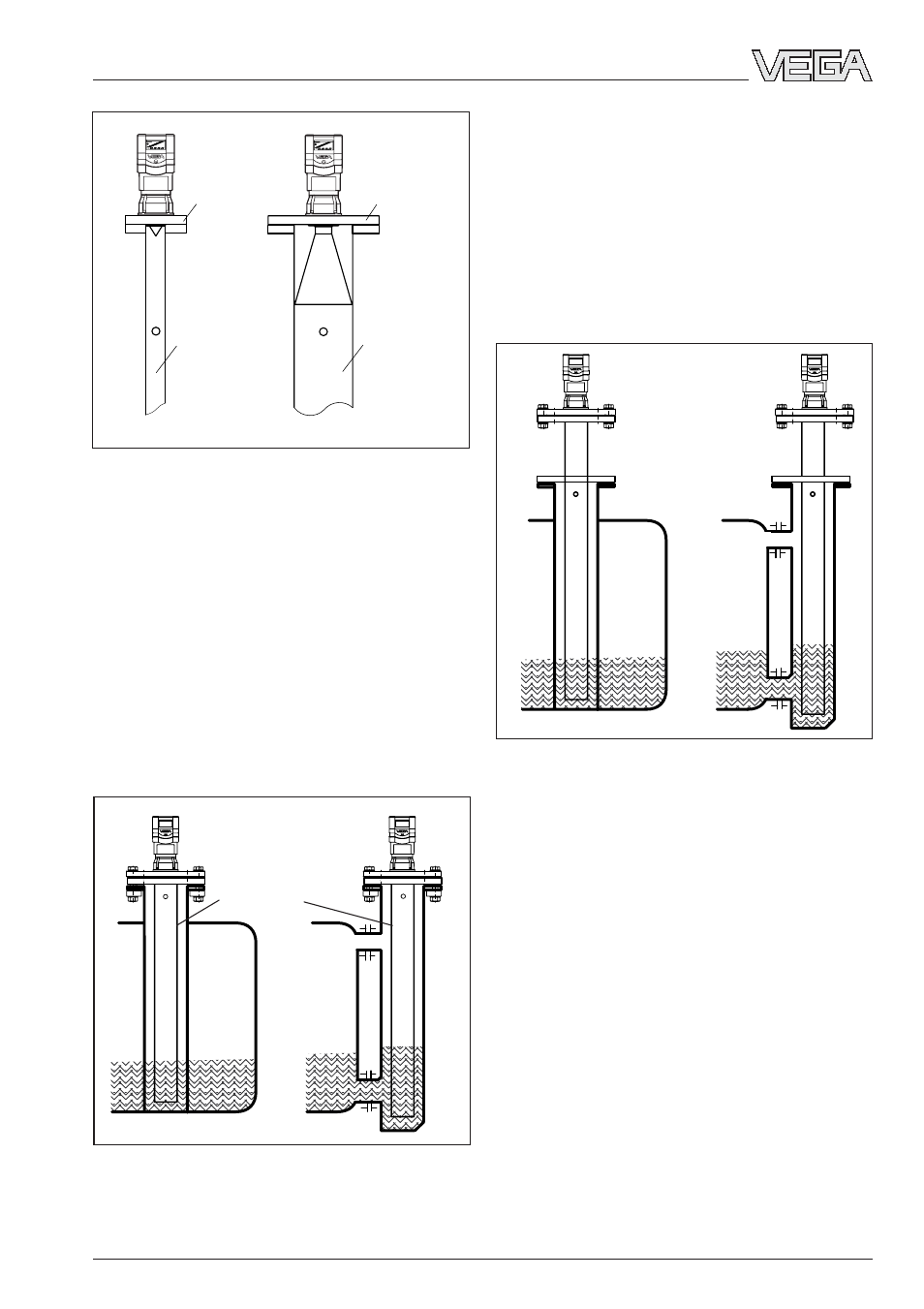

Guide tube in existing surge or bypass tube

Extended guide tube

Guide tube

Use of guide tubes

In case of very rough inner surfaces in exist-

ing bypass tubes (e.g. due to corrosion),

large connection openings as well as bypass

tubes with more than 100 mm inner diameter,

the use of a guide tube inside the existing

bypass tube is recommended. This reduces

the noise level and increases reliability con-

siderably. The flange of the guide tube can

be easily mounted as a sandwich flange

between vessel and sensor flange.

To increase the min. distance, the guide tube

can project out of the surge or bypass tube.

For this purpose, a plain flange can be

welded at the required position on the out-

side of the extended guide tube. In both

cases, a breather hole must be provided.

Seals on tube connections and tube ex-

tensions

Pipe antennas with DN 50, DN 80, DN 100 and

DN 150

DN 150

DN 50

ш 50

ш 150

Microwaves are very sensitive to gaps in

flange connections. If connections are made

without proper care, distinct false echoes as

well as increased signal noise can result.

Observe the following points:

• The seal used should correspond to the

tube inner diameter

• If possible, conductive seal made of mate-

rials such as conductive PTFE or graphite

should be used

• There should be as few seal positions as

possible in the guide tube.