Figure 5. spring-lock cut away, Periodic maintenance – Veris Verabar V150 Installation Instructions User Manual

Page 4

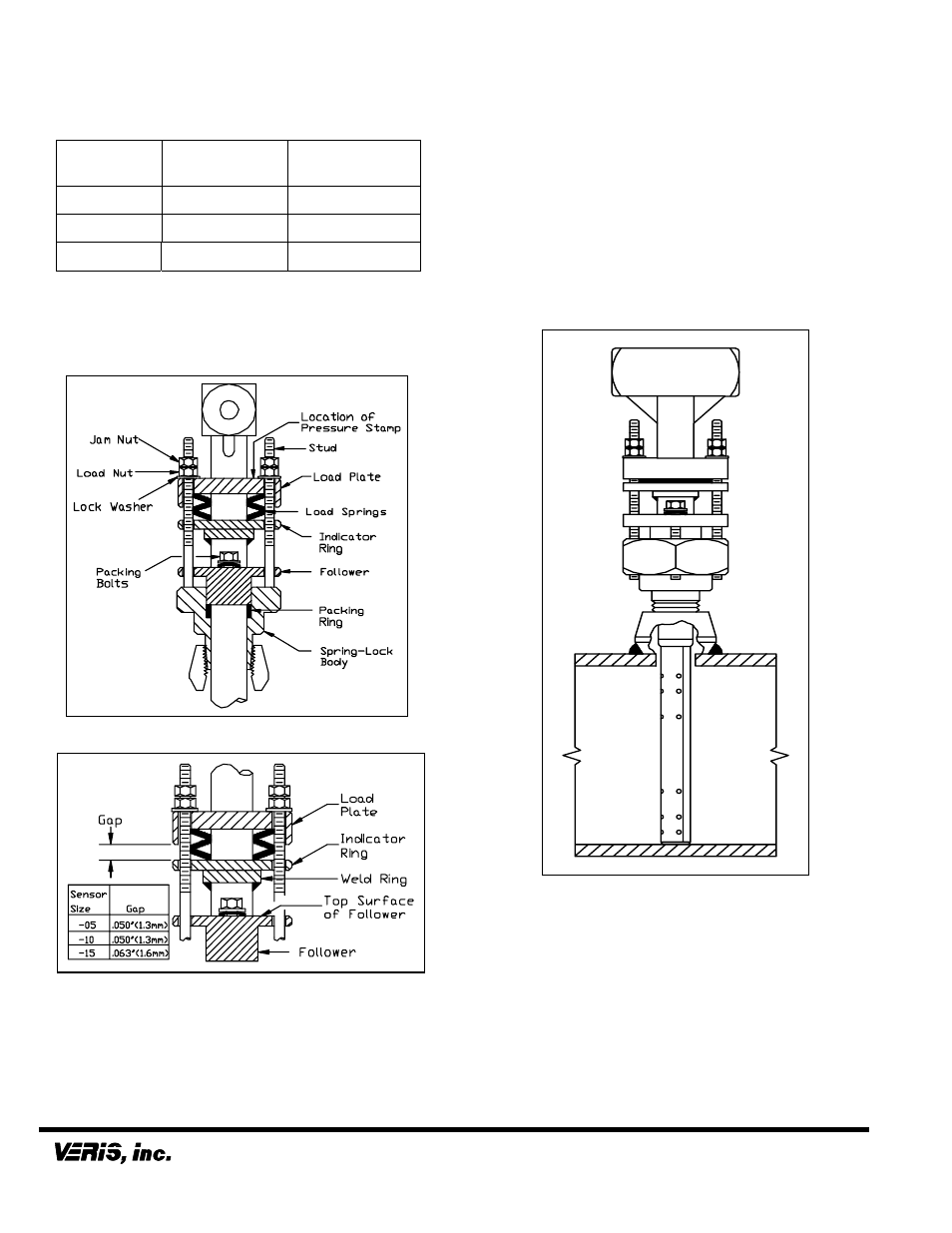

• Using a torque wrench, tighten the three packing

bolts to the appropriate torque value listed in the

table below.

Sensor Size

Packing Bolt

Torque (in-lbs)

Packing Bolt

Torque (ft-lbs)

–05 50 4.2

–10 100 8.3

–15 170 14.1

Note: The weld on the weld ring (Figure 6) should

not contact the top surface of the follower. If the weld

on the weld ring comes into contact with the follower,

the sensor will not be properly bottomed in the pipe.

If this occurs, consult the factory before proceeding.

Figure 5. Spring-Lock Cut Away

Figure 6. Proper Spring Compression

5.5

Install Instrument Valves or Manifold

5.5.1 Valves

If the Verabar does not have a valve head, install

instrument valves using proper thread sealant. Be sure

instrument shut-off valves are installed and shut prior to

repressurizing the pipe.

5.5.2 Manifold

If the Verabar has a direct or integral manifold, be sure

the high and low-pressure block valves are shut off

prior to repressurizing the pipe.

5.6

Pressurize Pipe and Retighten Bolts

Pressurize the pipe and check for leaks. If leaks are

present, retighten the packing bolts until leaking is

eliminated. Verify that the distance between the load

plate and the indicator ring is approximately 0.050”

(1.3mm) for –05 and –10 sensors and 0.063” (1.6mm)

for –15 sensors; make adjustments as required.

The Verabar is now properly installed (Figure 7).

Figure 7. Installed V150

Periodic Maintenance

The assembly should be periodically checked. Verify

that no leaks are present. Tighten the packing bolts if

necessary.

6315 Monarch Park Place

• Niwot, CO 80503 USA • Phone: (303) 652-8550

IO-150

-V

WI-CS-022 REV B (6/08)

Fax: (303) 652-8552

• Email: [email protected] • Website: www.veris-inc.com

Printed in USA