2weld threadolet to pipe, 4insert sensor – Veris Verabar V150 Installation Instructions User Manual

Page 3

5.2

Weld Threadolet to Pipe

• With the follower and packing rings already in

place, loosely insert the sensor into the Spring-

Lock body (see Figure 2). Thread the Spring-

Lock body into the threadolet (hand tight), then

insert the complete assembly into the pipe. This

will assure proper alignment of the threadolet to

the hole already drilled in the pipe.

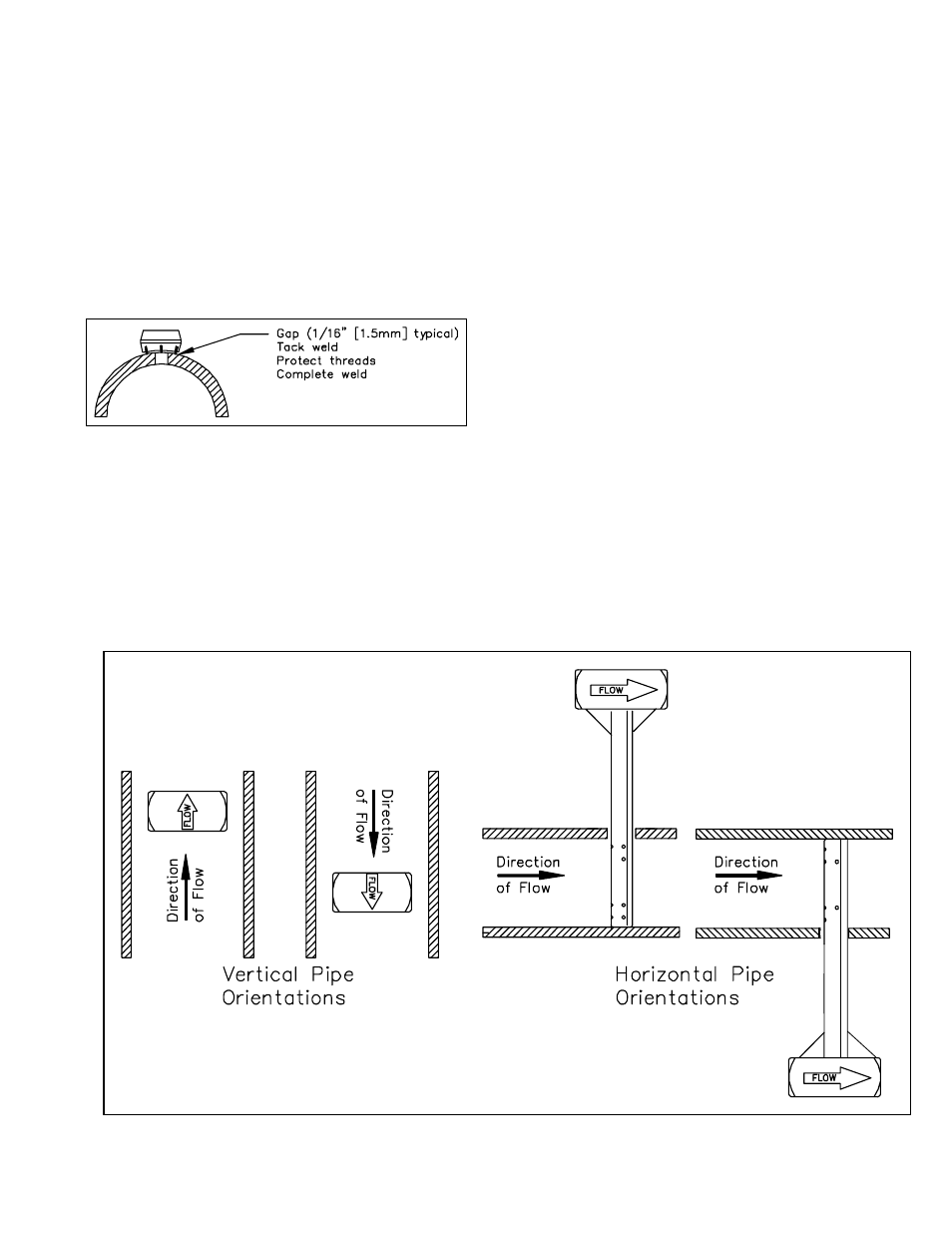

• Using the appropriate weld gap (1/16” [1.5mm]

typical), tack weld the threadolet into position,

then remove the sensor and Spring-Lock body.

Protect threads on the threadolet and finish

welding the threadolet to the pipe per applicable

codes (see Figure 3).

Figure 3. Weld Gap

5.3 Thread Packing Body into Threadolet

Using appropriate pipe thread sealant, thread the

Spring-Lock body into the threadolet.

5.4 Insert

Sensor

• With the follower and packing rings already in

place (factory assembled), insert the sensor into

the Spring-Lock body until the tip of the sensor

hits the opposite side of the pipe. Note, the three

studs must pass through the indicator ring and

the load plate.

• Align the head of the sensor so that the arrow

labeled “flow” on the head is in the direction of

the flow in the pipe to within 3° (Figure 4).

Maintain the head in this position for the

remainder of the installation.

• Place the three lock washers and the three load

nuts on the studs and tighten. Tighten the load

nuts until the load plate is 0.050” (1.3mm) from

the indicator ring for –05 and –10 sensors. For

–15 sensors, the load plate should be 0.063”

(1.6mm) from the indicator ring (Figure 6). For

–05 sensors, this can be done by tightening all

the load nuts until the load plate just touches the

indicator ring and then backing off all the load

nuts one complete turn. For –10 and –15

sensors, this can be done by tightening all the

load nuts until the load plate just touches the

indicator ring and then backing off all the load

nuts ¾ of a turn. The load springs are now

properly set.

• Thread on the three jam nuts and tighten until

they are resting hand-tight against the lock nuts.

Place a backup wrench on the load nut to

prevent it from rotating. While not allowing the

load nut to rotate, tighten the jam nuts 1/8 turn

beyond hand tight.

Figure 4. Orientation of Flow Arrow