Maximum safe operating speed – Spicer Driveline Installation Service Manual User Manual

Page 21

18

Installation Techniques

Maximum Operating

Speed

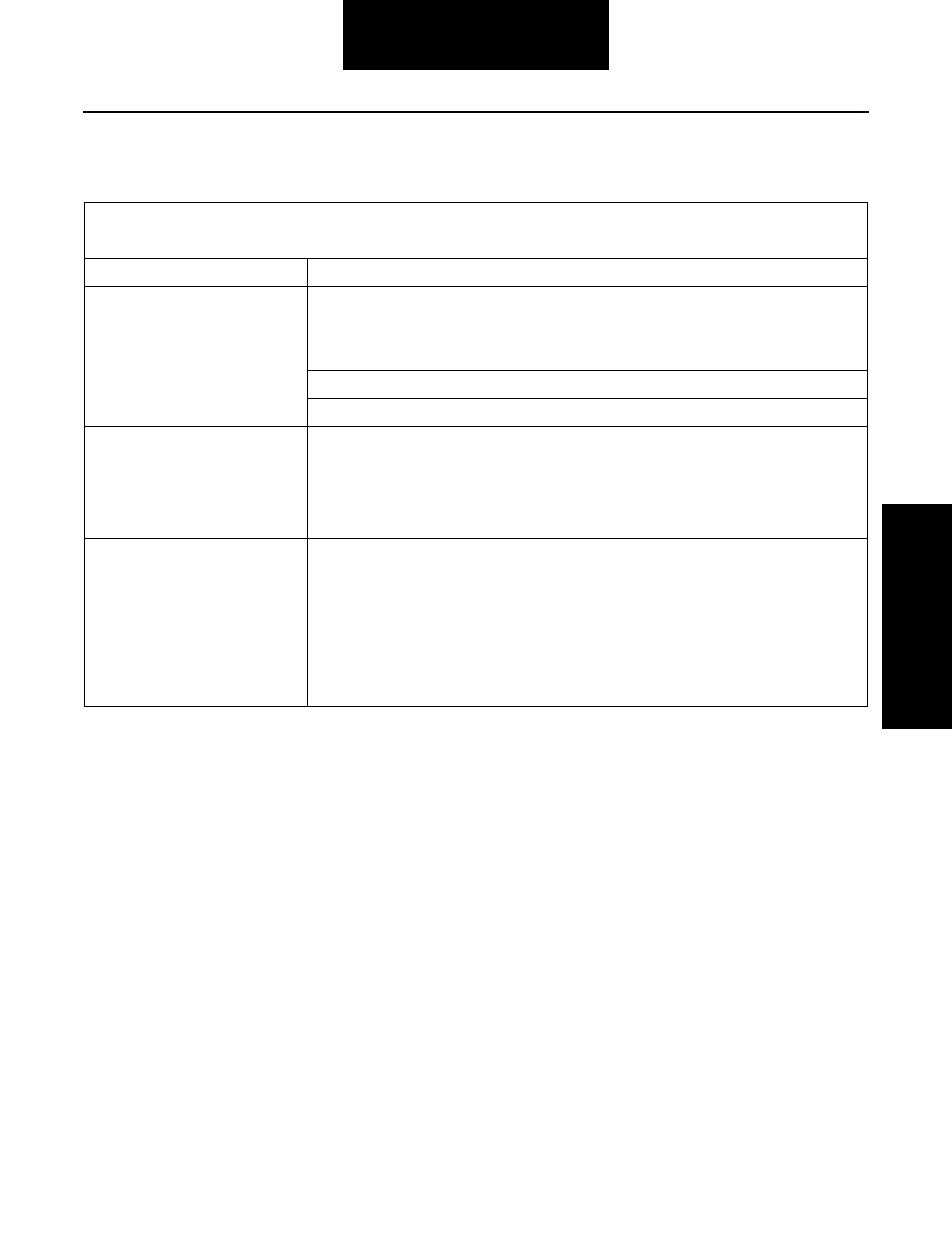

Maximum Safe Operating Speed

To prevent premature wear, auxiliary driveshaft breakage, and possible injury to people or equipment, be aware of the critical

speed of these types of driveshafts. Critical speed, explained earlier in this guide, is different for these solid shaft and small tube

driveshafts.

Refer to the chart above for maximum safe operating speed information on these types of shafts.

If the chart indicates that the critical speed may be a problem, use multiple shafts. Be sure to use support bearings where neces-

sary and set up the true universal joint operating angles as indicated earlier in this guide.

As with all driveshafts, auxiliary driveshafts should be:

•

Carefully installed to minimize vibrations caused by incorrect universal joint operating angles

•

Capable of absorbing shock loads

•

Capable of changing length as needed

•

Guarded so as to prevent inadvertent entanglement

MAXIMUM OPERATING SPEED* BY TUBE SIZE, SOLID SHAFT SIZE, AND LENGTH

*(For speeds over 6000 RPM, contact Spicer Universal Joint Division Engineering)

TUBING

MAXIMUM INSTALLED LENGTH (IN INCHES) FOR GIVEN RPM

Diameter

Centerline to Centerline of Joints for a Two Joint Assembly

&

or

Wall Thickness

Centerline of Joint to Centerline of Center Bearing for a Joint and Shaft

W - Welded

RPM - Revolutions Per Minute

S - Seamless

1000

1500

2000

2500

3000

3500

4000

4500

5000

5500

6000

1.750" x .065" W

82"

67"

58"

52"

-

-

-

-

-

-

-

1.250" x .095" S

64"

52"

45"

40"

37"

34"

32"

-

-

-

-

2.500" x .083" W

87"

70"

62"

55"

50"

45"

43"

41"

39"

37"

35"

3.000" x .083" W

-

-

85"

76"

70"

64"

60"

57"

54"

51"

49"

SOLID SHAFT DIAMETER

.750"

42"

35"

30"

27"

25"

-

-

-

-

-

-

.812"

44"

36"

31"

28"

26"

-

-

-

-

-

-

.875"

46"

37"

32"

29"

27"

-

-

-

-

-

-

1.000"

49"

40"

35"

31"

28"

-

-

-

-

-

-

1.250"

55"

45"

39"

35"

32"

-

-

-

-

-

-