Installation techniques midship mounted components – Spicer Driveline Installation Service Manual User Manual

Page 19

16

Installation Techniques

Midship Mounted

Components

Mounting a Midship-Mounted PTO, Pump, or Auxiliary Transmission

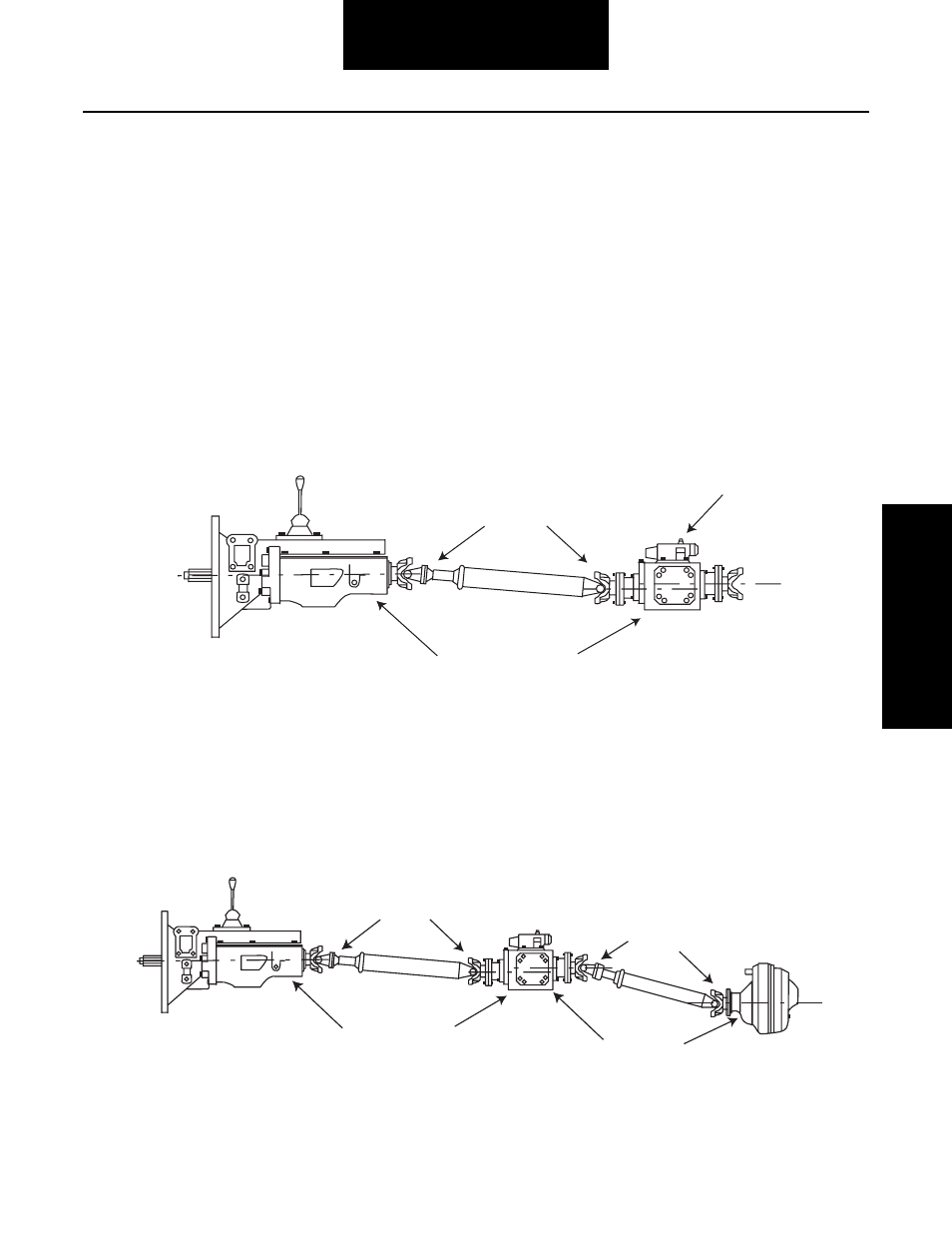

When installing a midship-mounted PTO, auxiliary transmission, or midship-mounted pump into the main driveline of a vehicle,

install it at the same angle as the transmission. Keep the offset to a minimum to reduce universal joint operating angles.

Note: Do not make the universal joint operating angle less than 1/2 degree.

Before bolting the device in place, check the universal joint operating angles that occur at each end of the driveshaft. They must

be 1 to 1-1/2 degrees and they must be equal to within 1/2 degree for this type of application.

If the device ends up being installed in direct line with the transmission, with little or no universal joint operating angle on the

joints, raise or lower it so there is enough offset to create the required 1 to 1-1/2 degree universal joint operating angle on each

end of the driveshaft. (See Fig. 12)

If there is only one driveshaft between the device and the rear axle, rotate the rear axle (using shims in the appropriate place) so

it is the same angle as the device. This makes the universal joint operating angle at each end of the driveshaft equal (See Fig. 13).

Check the size of the universal joint operating angles to determine if they meet recommendations.

Figure 12

Figure 13

1/2

0

minimum

1

0

to 1-1/2

0

recommended

3

0

maximum

Equal within 1/2

0

Install at same angle

and in-line in top view

Auxiliary

Device

Install at same angle

and in-line in top view

Check size of

these angles

Rotate axle to same

angle as Auxiliary

Device

1/2

0

minimum

1

0

to 1-1/2

0

recommended

3

0

maximum

Equal within 1/2

0