04_cmyk – GE Healthcare TRACERcenter User Manual

Page 5

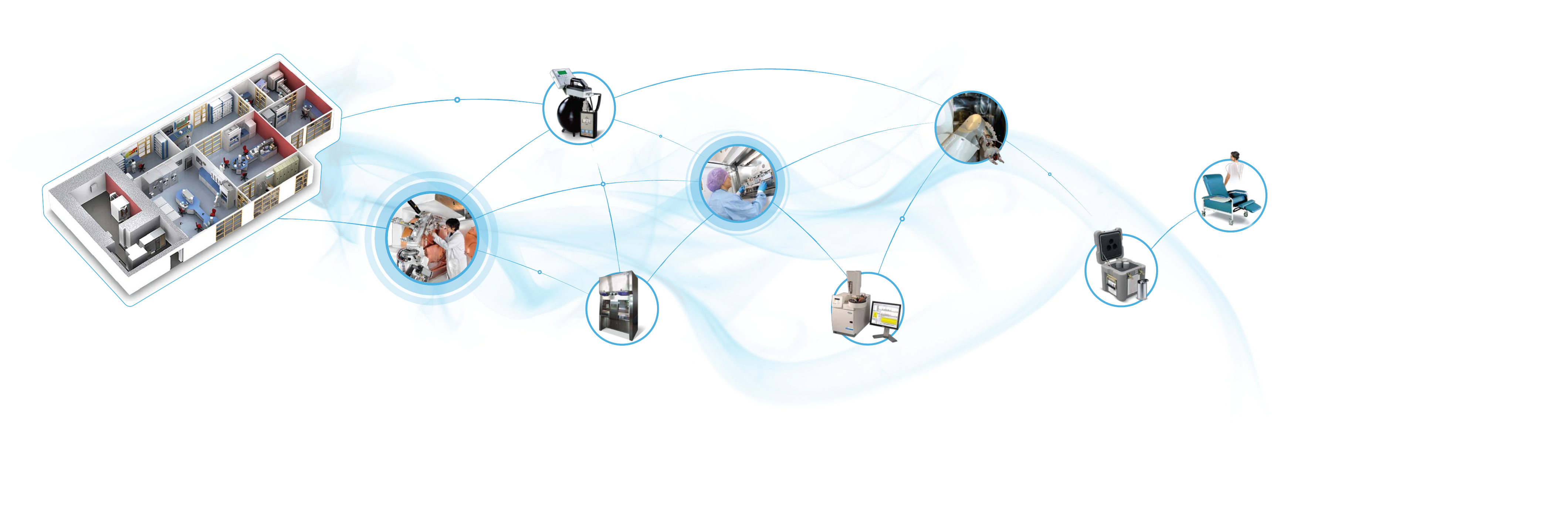

GE chemistry synthesizers

QC equipment

Radiation monitoring

Hotcells and fume hoods

Patient Prep Lab

Shielding and lead containers

PETtrace

cyclotrons

Dispensing systems

Customize

your PET center

with our full support

every step of the way.

Understanding disease

begins in the production lab.

Producing PET tracers requires sophisticated laboratories with a wide range of advanced equipment. With TRACERcenter, we

can help simply the process by custom-designing a tracer-production facility to meet your specific needs.

The result: a solution that enables compliance with GMP guidelines, to help ensure that the radiotracers you produce are of the

highest quality, offering maximum safety and efficacy.

While our PETtrace cyclotron series sets

the pace for production flexibility and

reliability today, we are committed to

providing you with an affordable upgrade

path that helps protect your investment

for many years to come.

PETtrace cyclotrons

Your hotcell and fume hood requirements

will depend in part on whether you’re using

the equipment for research, distribution or

in-house production. That’s why we offer a

complete selection of products to meet

your requirements while addressing both

radioprotection safety and GMP guidelines.

Every single one is compatible with, or

configurable to, the full line of GE

Healthcare chemistry synthesizers.

Hotcells and fume hoods

Whether your tracers start from

18

F-fluoride,

18

F-F

2

or

11

C-carbon dioxide or

methane, you’ll find just the right

synthesizer for your production and

research needs within the GE FASTlab and

TRACERlab* families.

GE chemistry synthesizers

When it comes to dispensing and

fractionating the patient dose, accuracy

and efficiency are key. Whatever your

preferences – vial or syringe delivery,

automatic or manual operation –

TRACERcenter will configure the best

solution for your facility.

Dispensing systems

Designing a quality control lab is one of

the most complicated tasks associated

with tracer production, in part because it

requires integrating many different

technologies from many different

vendors. But it’s no problem for the

experts at TRACERcenter – nor is adhering

to regional regulatory guidelines along

the way.

QC equipment

Radiation monitoring is critical to

safeguarding personnel and patients in

any PET facility. Count on TRACERcenter

to provide you with all the necessary

technology, equipment, and guidance to

help you make yours the safest possible

environment.

Radiation monitoring

Reducing operator exposure to

radioactive material is always a priority

for a tracer-production facility. This is the

reason TRACERcenter offers such a wide

range of solutions, from shielded

workbenches to lead containers.

Shielding and lead containers

Time is important in any imaging facility. But nowhere is it more important than

in a PET center, where radiopharmaceuticals’ short half-lives combine with tight

scanner scheduling to make efficiency critical.

One excellent solution: the TRACERcenter Patient Prep Lab, designed and

equipped to help you manage virtually any patient load with confidence and ease.

Patient Prep Lab

There’s nothing simple about establishing an in-house PET tracer-production and

imaging center. It mandates expertise in disciplines from siting and

pharmaceutical production to handling radioactive substances and licensing. It

also mandates a major investment in multiple technologies.

Fortunately, TRACERcenter offers you all the expertise you need to help you

establish a successful PET program; all the technology; and all the step-by-step

support you want to bring your PET facility to life.

Among the tools:

Site-readiness and project - management support.

Carefully selected, qualified equipment with the requisite installation -and

operation - qualification (IQ/OQ) protocols.

The documentation (Standard Operating Procedures, or SOP) needed to operate

a facility under GMP guidelines.

On-site training, provided by GMP specialists, on performing GMP and FDG

process qualification and validation (PQ/PV).