Icons, Laser classification, Electromagnetic compatibility (emc) – RIDGID micro CL-100 User Manual

Page 8: Changing/installing batteries, Pre‑operation inspection

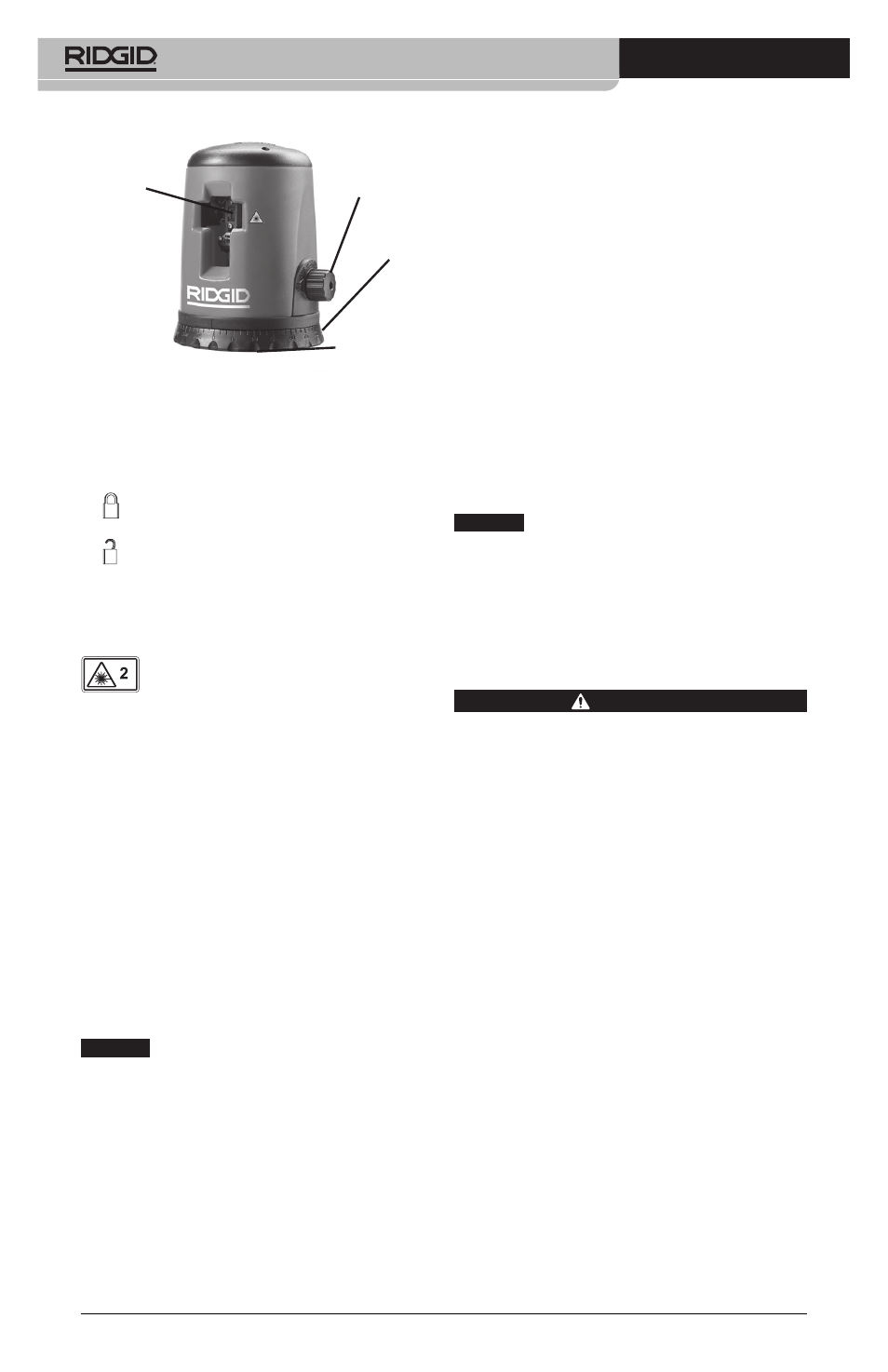

micro CL-100 Self-Leveling Cross Line Laser

6

Laser

Window

ON/OFF

Switch

Gradient Base

Figure 2 - Laser Parts

5

/

8

- 11 Thread

for Mounting

Icons

LOCK

UNLOCK

Laser Classification

The RIDGID micro CL-100 Self- Leveling

Cross Line Laser generates visible laser

beams that are emitted from the front of the de-

vice.

The device complies with class 2 lasers ac-

cording to: EN 60825-1:1994/A11:1995/-

A2:2001/A1:2002

Electromagnetic

Compatibility (EMC)

The term electromagnetic compatibility is

taken to mean the capability of the prod-

uct to function smoothly in an environment

where electromagnetic radiation and elec-

trostatic discharges are present and without

causing electromagnet interference to other

equipment.

NOTICE

The RIDGID micro CL-100 Self-Leveling

Cross Line Laser conforms to all applicable EMC

standards. However, the possibility of them

causing interference in other devices cannot be

precluded.

Changing/Installing

Batteries

The RIDGID micro CL-100 Self-Leveling Cross

Line Laser is supplied without batteries in-

stalled. Remove the batteries prior to long

term storage to avoid battery leakage.

1. Make sure the laser is OFF (ON/OFF switch

turned fully counter clockwise).

2. Remove the battery cover by depressing

the tab (Figure 3). If present, remove the

white sensormatic tag from the battery

compartment. Remove the batteries if

needed.

3. Install three AAA (LR03) batteries into

battery holder, observing the correct

polarity as indicated in the battery com-

partment.

NOTICE

Use batteries that are of the same

type. Do not mix battery types. Do not mix

new and used batteries. Mixing batteries can

cause overheating and battery damage.

4. Securely replace the battery cover.

Pre‑Operation Inspection

WARNING

Before each use, inspect your laser and cor‑

rect any problems to reduce the risk of in‑

jury and prevent tool damage.

Do not look into the laser beam. Looking

into the laser beam may be hazardous to

the eyes.

1. Make sure the unit is OFF and the sel-

fleveling mechanism locked (ON/OFF

switch turned fully counterclockwise).

2. Remove the batteries and inspect for

signs of damage. Replace batteries if

necessary. Do not use equipment if the

batteries are damaged.

3. Clean any oil, grease or dirt from the

equipment. This aids inspection and

helps prevent the tool from slipping

from your grip.

4. Inspect the laser for any broken, worn,

missing or binding parts or any condi-

tion which may prevent safe and normal

operation.

5. Check that the warning labels are pres-

ent, firmly attached and readable.