Tool and work area set-up, Operating instructions, Using the imager – RIDGID Seesnake Micro User Manual

Page 6: Seesnake micro, Typical applications

Ridge Tool Company

Tools For The Professional

TM

SeeSnake Micro™

Tool and Work Area Set-Up

WARNING: To prevent serious injury, proper set-up of the tool and work

area is required. The following procedures should be followed:

1. Review General Safety Information section of this manual (Page 2).

2. Check work area for:

• Adequate lighting

• Flammable liquids, vapors or dust that may ignite.

3. Follow tool set-up according to specific tool operator’s manual.

Operating Instructions

CAUTION: Do not use excessive force to insert or bend the cable.

Do not use the cable or imager head to modify surroundings, clear pathways or

clogged areas, or as anything other than an inspection device.

The hand-held display unit is not water resistant.

The imager head and its covering are water resistant, but are not acid-proof

or fireproof. Petroleum-based products will ruin the imager head’s protective

plastic covering over time. Avoid submersing the imager head into corrosive,

oily places.

Using The Imager

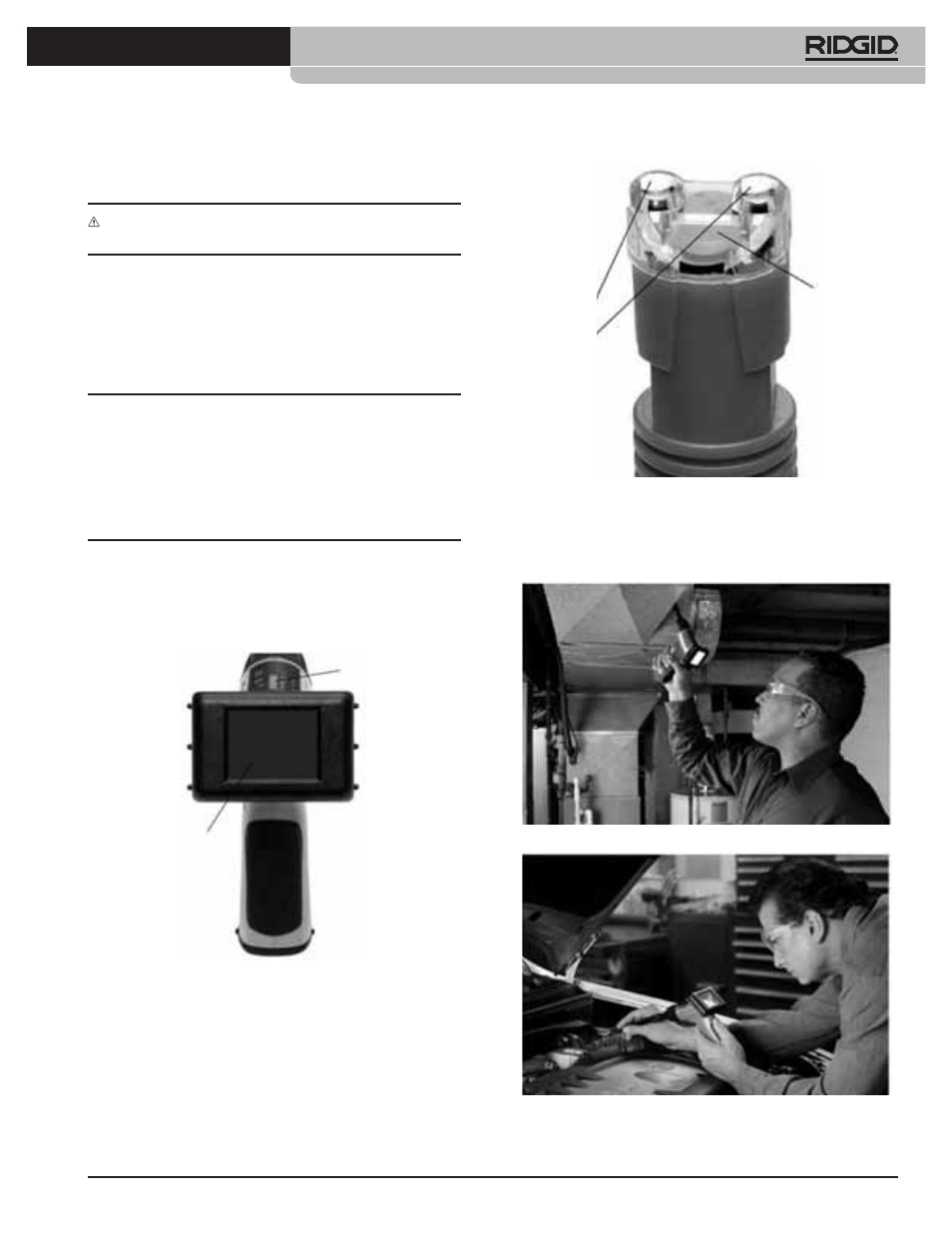

To turn the unit on, hold the viewer with the LCD screen facing you (Figure 7).

Roll the ON/OFF switch away from you to turn on the screen. The switch then

acts as a dimmer for the twin LEDs (Figure 8) that surround the camera on the

imager head and provide lighting.

Figure 7

Figure 8

Typical Applications

The SeeSnake Micro™ is designed as a remote inspection device. Typical

applications might include HVAC inspection (Figure 9), automotive inspection

(Figure 10), cable routing, automotive/boat/aircraft inspection, etc.

Figure 9

Figure 10

ON/OFF Switch

LCD Screen

Camera

LEDS