York LY8S User Manual

Page 6

036-21618-003 Rev. A (1205)

6

Unitary Products Group

HORIZONTAL SIDEWALL VENTING

For applications where vertical venting is not possible, the

only approved method of horizontal venting is the use of an

auxiliary power vent. Approved power venters are Fields

Controls Model SWG-4Y or Tjernlund Model GPAK-JT. Fol-

low all application and installation details provided by the

manufacturer of the power vent. This unit may be horizontally

vented using 4” (10.2 cm) diameter pipe with a minimum

length of 4.5 feet (1.37 m) and a maximum length of 34.5 feet

(10.82 m) with up to 4 elbows.

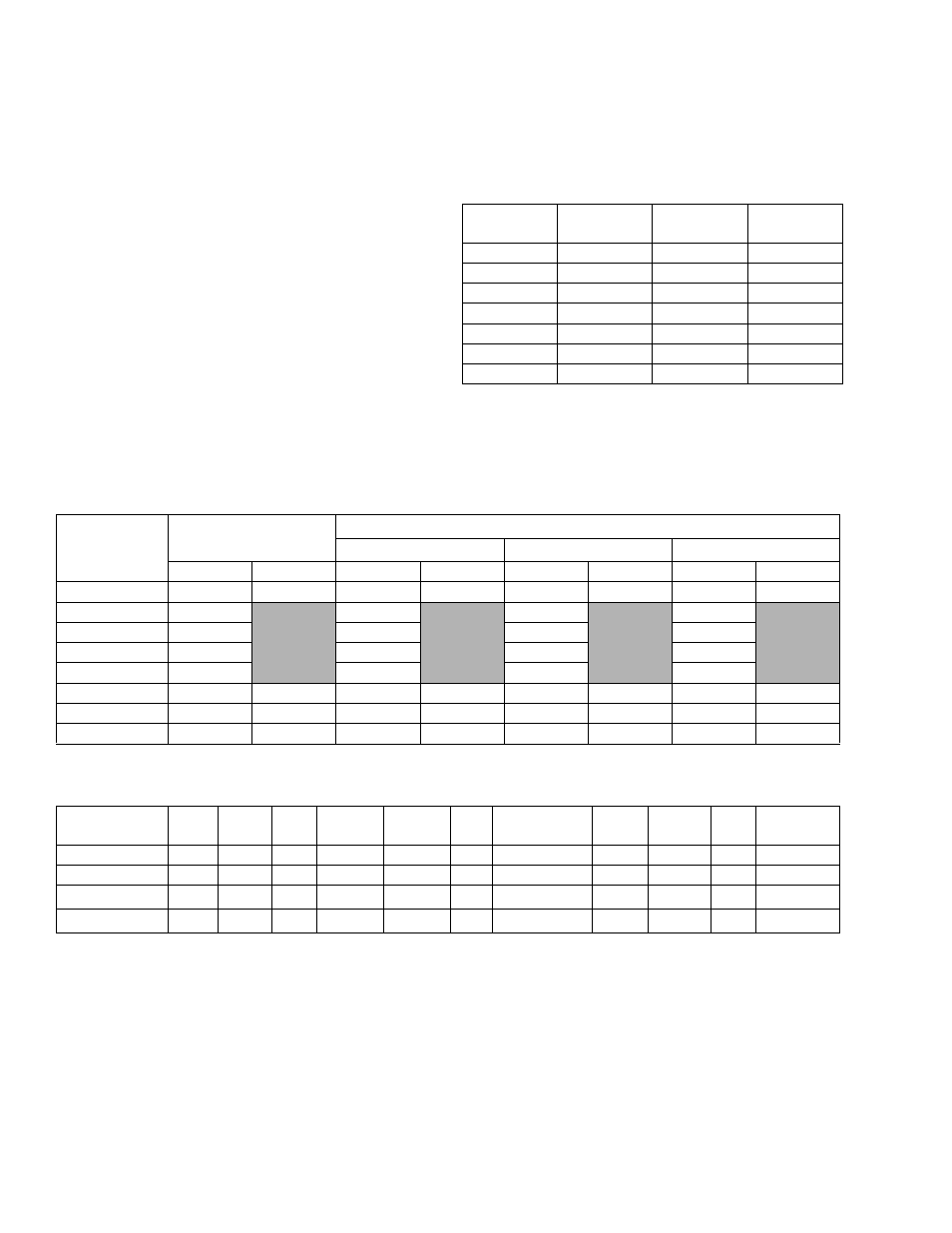

FILTER PERFORMANCE

The airflow capacity data published in the “Blower Perfor-

mance” table listed above represents blower performance

WITHOUT filters. To determine the approximate blower per-

formance of the system, apply the filter drop value for the fil-

ter being used or select an appropriate value from the “Filter

Performance” table shown below.

NOTE: The filter pressure drop values in the “Filter Perfor-

mance” table shown below are typical values for the type of

filter listed and should only be used as a guideline. Actual

pressure drop ratings for each filter type vary between filter

manufacturer.

NOTES:

1. Air velocity through throwaway type filters may not exceed 300

feet per minute. All velocities over this require the use of high

velocity filters.

2. Air flows above 1800 CFM require either return from two sides or

one side plus bottom.

FILTER SIZES

CFM

Cabinet

Size

Side

(in)

Bottom

(in)

1200

A

16 x 25

14 x 25

1200

B

16 x 25

16 x 25

1600

B

16 x 25

16 x 25

1600

C

16 x 25

20 x 25

2000

C

(2) 16 x 25

20 x 25

2200

C

(2) 16 x 25

20 x 25

2000

D

(2) 16 x 25

22 x 25

FILTER PERFORMANCE - PRESSURE DROP INCHES W.C.

Airflow

Range

Minimum

Opening Size

Filter Type

Disposable

Washable Fibers

Pleated

1 Opening

2 Openings

1 Opening

2 Openings

1 Opening

2 Openings

1 Opening

2 Openings

CFM

In³

In³

inwc

inwc

inwc

inwc

inwc

inwc

0 - 750

230

0.01

0.01

0.15

751 - 1000

330

0.05

0.05

0.2

1001 - 1250

330

0.1

0.1

0.2

1251 - 1500

330

0.1

0.1

0.25

1501 - 1750

380

658

0.15

0.09

0.14

0.08

0.3

0.17

1751 - 2000

380

658

0.19

0.11

0.18

0.1

0.3

0.17

2001 & Above

463

658

0.19

0.11

0.18

0.1

0.3

0.17

UNIT CLEARANCES TO COMBUSTIBLES (ALL DIMENSIONS IN INCHES, AND ALL SURFACES IDENTIFIED WITH THE

UNIT IN AN UPFLOW CONFIGURATION)

Application

Top

Front

Rear

Left

Side

Right

Side

Flue

Floor/

Bottom

Closet

Alcove

Attic

Line

Contact

Upflow

1

6

0

0

3

6

Combustible

Yes

Yes

Yes

No

Upflow B-Vent

1

3

0

0

0

1

Combustible

Yes

Yes

Yes

No

Horizontal

1

6

0

0

3

6

Combustible

No

Yes

Yes

Yes

1

Horizontal B-Vent

1

3

0

0

0

1

Combustible

No

Yes

Yes

Yes

1

1. Line contact only permitted between lines formed by the intersection of the rear panel and side panel (top in horizontal postion) of the furance jacket

and building joists, studs or framing.