Wire gauge and torque requirements, Grounding – Xantrex Technology PV225S-480-P User Manual

Page 60

Installation

3–12

152606

Wire Gauge and Torque Requirements

Table 3-1 provides acceptable wire gauges, bolt sizes, and torque values for AC

terminal connections.

Table 3-2 provides acceptable wire gauges, bolt sizes, and torque values for DC

terminal connections.

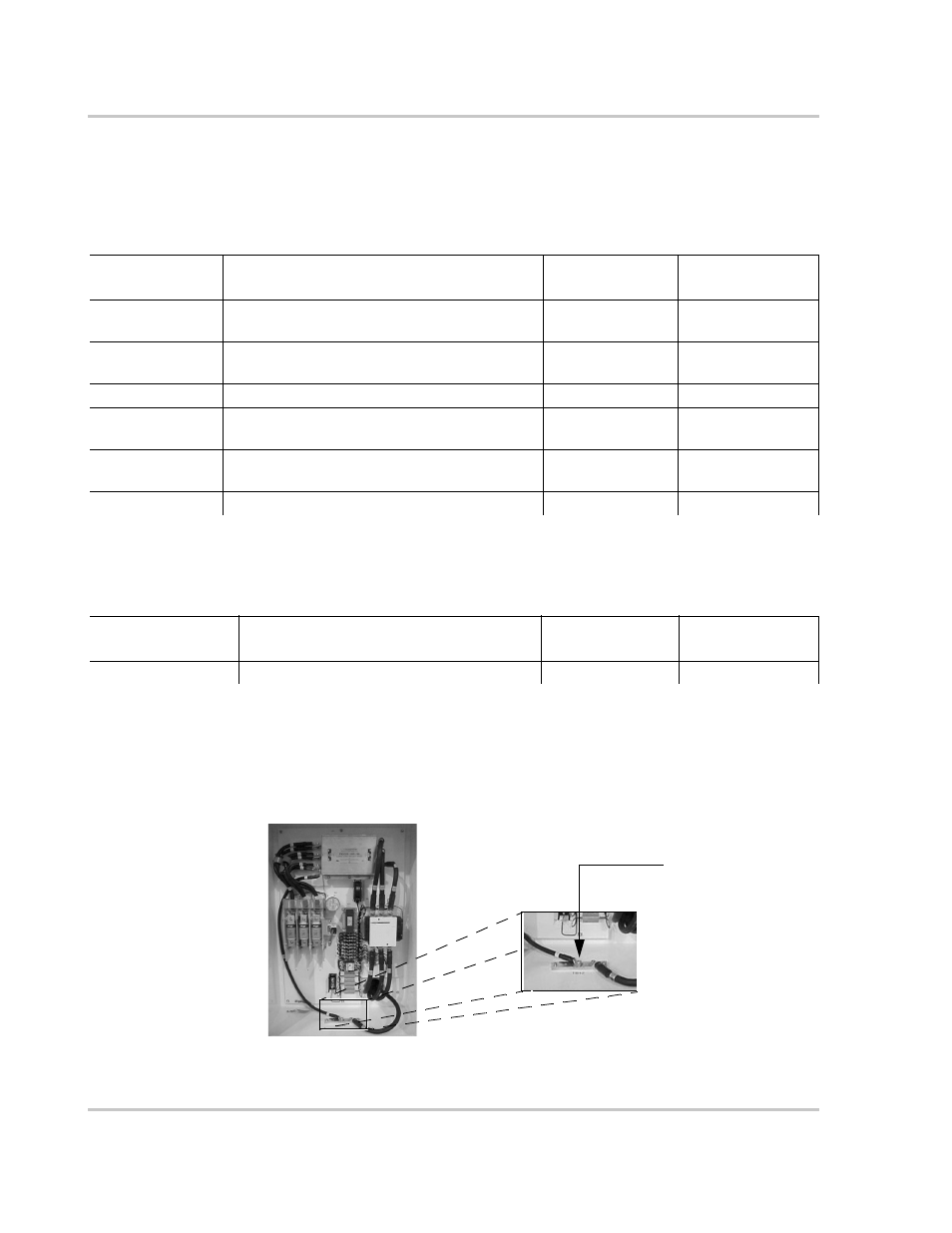

Grounding

System Grounding

Install a copper ground rod within three feet of the PV225S enclosures per the

National Electric Code ANSI/NFPA 70. The single-point ground for the system is

to be made at the AC ground bar (TB12) in the AC Interface Enclosure.

Table 3-1 AC Terminal Wire Gauge, Bolt Size, and Torque Values

AC Terminal

Connections

Acceptable Wire Size Range

(both models)

Bolt (Hardware)

Size

Torque

Requirements

TB1

(Chassis Ground)

500MCM to #4 AWG (1 stud per pole)

3/8-16

420 in-lb (47.5 Nm)

TB12

(System Ground)

500MCM to #4 AWG (1 stud per pole)

3/8-16

420 in-lb (47.5 Nm)

TB11 (Neutral)

500MCM to #4 AWG (1 stud per pole)

3/8-16

228 in-lb (25.7 Nm)

S1-2T1, S1-4T2,

S1-6T3

350MCM to #6 AWG (1 stud per phase)

M10 (See Caution

on page 3–18)

310 in-lb (35.0 Nm)

T6-X1, T6-X2,

T6-X3

350MCM to #6 AWG (2 studs per phase)

3/8-16

420 in-lb (47.5 Nm)

TB5, TB6, TB7

350MCM to #4 AWG (6 openings per phase)

3/8 Hex

375 in-lb (42.4 Nm)

Table 3-2 DC Terminal Wire Gauge, Bolt Size, and Torque Values

DC Terminal

Connections

Acceptable Wire Size Range

(both models)

Bolt (Hardware)

Size

Torque

Requirements

S2-6, K2-6T3, TB4

600MCM to #4 AWG (2 openings per pole)

1/2 Hex

600 in-lb (67.8 Nm)

Figure 3-10 Single-point Ground (TB12) Ground Bar

AC Ground Bar

(TB12) to be used

for the Single Point

Ground

AC Interface Enclosure