Warning, Setting trolley close position – Wayne-Dalton PRODRIVE 3222C-Z User Manual

Page 19

Please Do Not Return This Product To The Store. Call Us Directly! Our Trained Technicians Will Answer Your Questions and/or Ship Any Parts You May Need

You can reach us Toll Free at 1-888-827-3667 for Consumer Assistance or online at www.wayne-dalton.com

13

OPEN

CLOSE

MORE

LESS

MORE

TRAVEL ADJUSTMENT

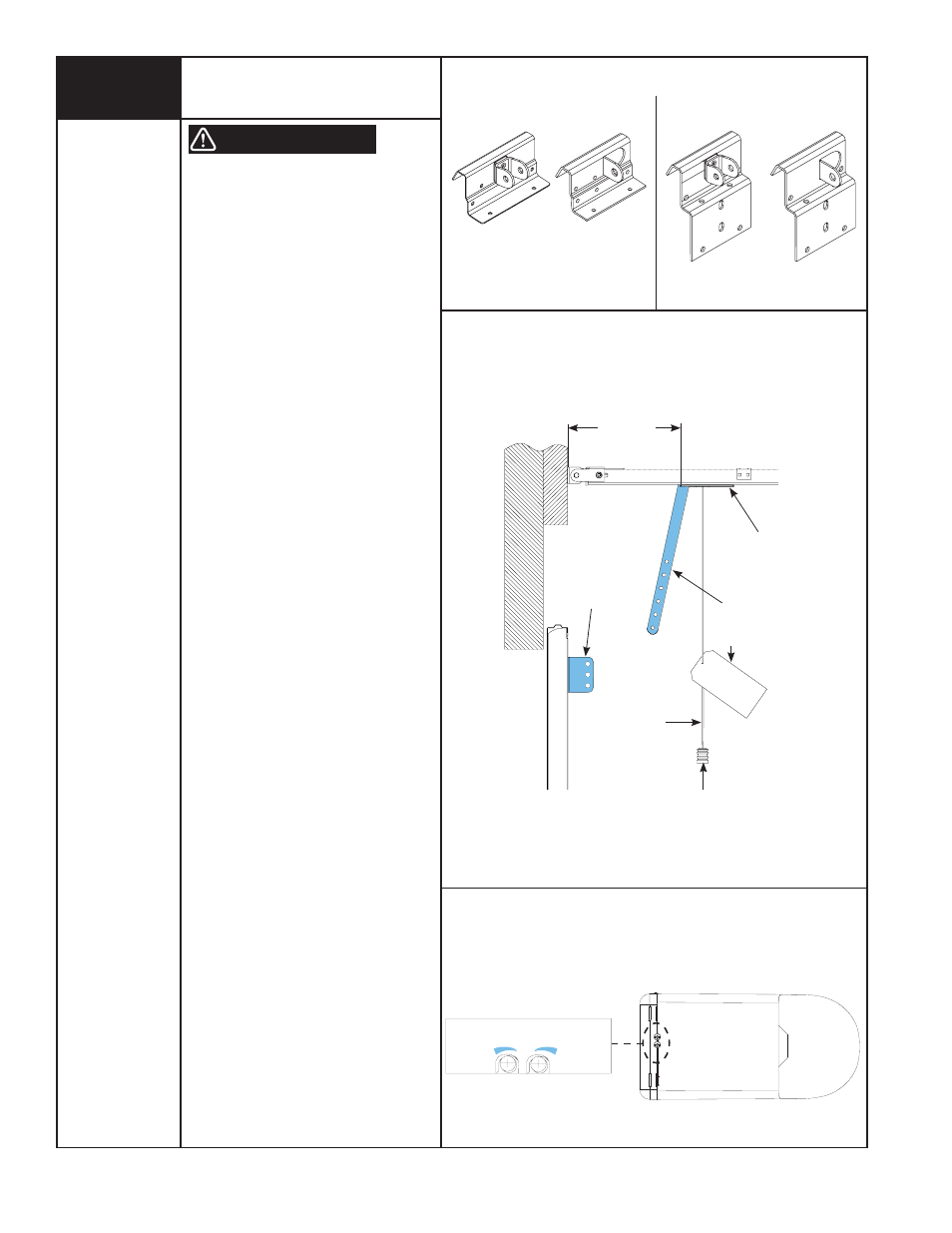

Setting Trolley Close Position

17

Tools Needed:

Pliers/Wire Cutters

Tape Measure

Flat Tip

Screwdriver

Bottom Of Opener

Door Bracket

Upper Arm

Trolley

(Closed Limit Position)

11” to 13”

(13” Minimum

For Belt Drive)

Pull Knob

Release Cord

Tag

WARNING

Models: 9100, 9400, 9600, 5120 and 5140.

Single and Double Tab Door Brackets

Model: 9700

Single Tab

Bracket

Double Tab

Bracket

Single Tab

Bracket

Double Tab

Bracket

TO AVOID POSSIBLE INJURY OR

PROPERTY DAMAGE, KEEP PEOPLE AND

OBJECTS CLEAR OF THE MOVING DOOR

ARM.

NOTE: If necessary, activate the opener

to move the trolley/ upper door arm to the

closed position.

NOTE: If you have a 9100, 9400,9600,

5120, 5140 or 9700 series door, with one of

the door brackets shown at the right and a

Torquemaster

®

or Extension Spring(s)

counterbalance system, see “Setting Trolley

Close Position/ Connecting Door Arm To

Door” on pages 23-24. If not, complete this

step.

NOTE: If you have a 9100, 9400, 9600,

5120, 5140 or 9700 series door, with one of

the door brackets shown at the right and a

Torsion Spring(s), see “Setting Trolley Close

Position/ Connecting Door Arm To Door” on

pages 25-26. If not, complete this step.

Trolley and latch assembly must be at the

factory preset fully closed position, (see

illustration).

Verify preliminary trolley and latch assembly

close position is 11” to 13” between trolley

clevis pin and the inside face of the door.

If adjustment of the trolley/latch assembly

position is required, use the close travel

adjustment screw located on the bottom of

the opener. A 1/4 turn equals approximately

1” of trolley travel; turn clockwise to de-

crease distance between header and trolley

and counter-clockwise to increase distance

between header and trolley.