Warning, Lift handles, Step plate – Wayne-Dalton 8300 User Manual

Page 7: Vertical track assemblies

Please Do not Return This Product To The Store. Contact your local Wayne-Dalton dealer. To find your local Wayne-Dalton dealer,

refer to your local yellow pages business listings or go to the find a Dealer section online at www.wayne-dalton.com

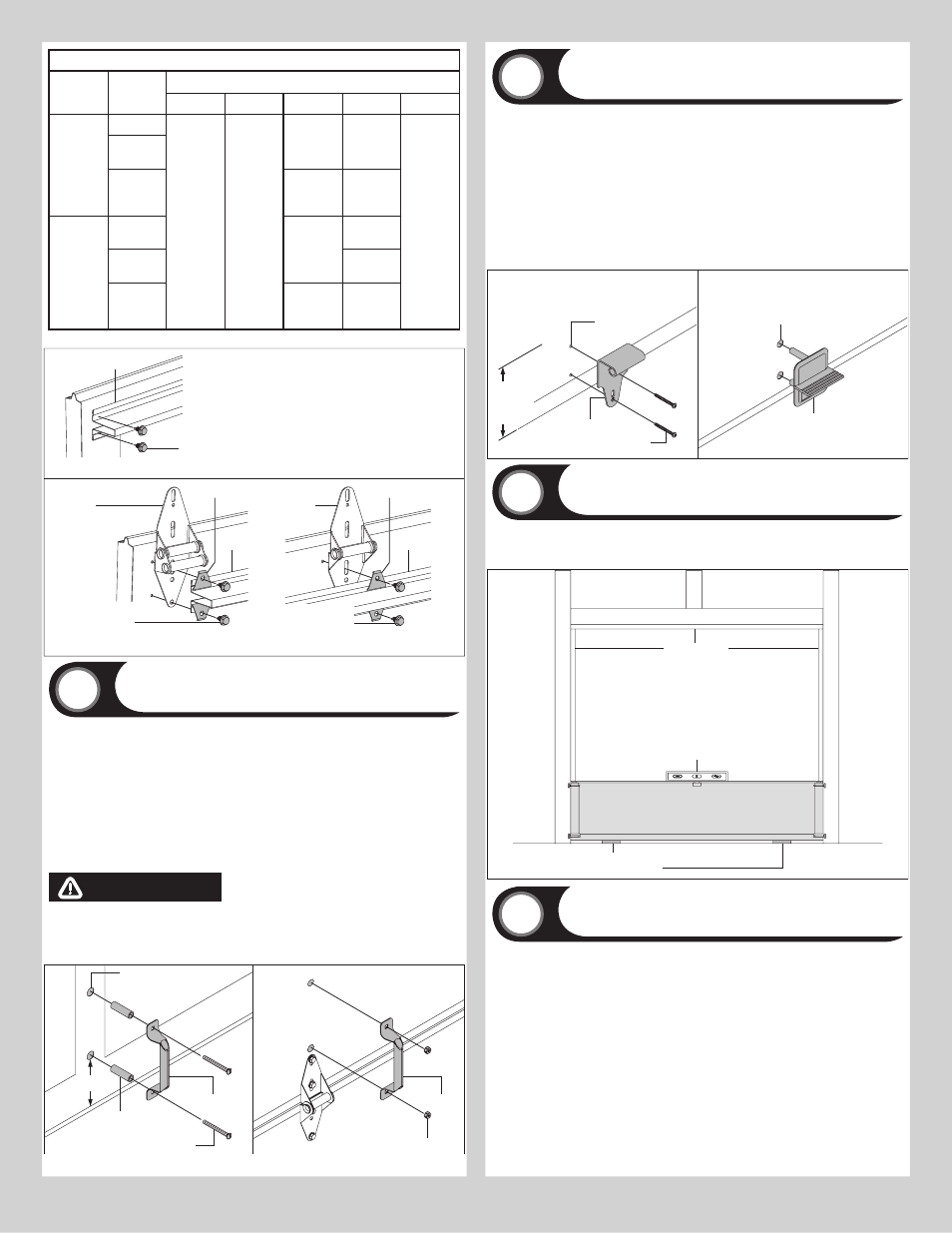

8500 LT-coM Steel Strutting Schedule---Brown colored Doors

Section

quantity

Configu-

ration

Door Width

6’-9’

10’

12’-16’

17’-18’

20’

5

Solid

n/A

2*T

2*T, 2~Y,

2*x, 2*B

3*T, 3~Y,

3*x, 3*B

n/A

Windows-

Top

Windows-

Interme-

diate

2*T, 2~W,

2*x, 2*B

3*T, 3~W,

3*x, 3*B

6

Solid

2*T, 2~Y,

2*x, 2*B

3*T, 3~Y,

3*x, 3*B

Windows-

Top

3*T, 3~Y,

3*x, 3*B

Windows-

Intermedi-

ate

2*T, 2~W,

2*x, 2*B

3*T, 3~W,

3*x, 3*B

(2) Strut clips

(2) 1/4”-20 x 7/8”

Self drilling screws

(2) 1/4”-20 x 7/8”

Self drilling screws

End hinge

Center hinge

U-bar installation across end and center hinges

U-bar installation at top of section

U-bar

(2) Strut clips

U-bar

(2) 1/4”-20 x 7/8”

Self drilling screws

U-bar

Lift handles

4

Tools: Tape Measure, Power Drill, 9/32”, 1/2” Drill Bit, 7/16” Wrench

NOTE: Refer to door section identification, located in the pre-installation section of this

manual.

Locate the vertical center of the lock (second) section of the door and position the lift

handle’s bottom hole 4” from the bottom of the lock section along the vertical center on the

outside of the door. use the holes in the lift handle as a template to mark the hole locations.

IMPORTANT: THE LIfT HAnDLE AnD THE STEP PLATE nEED TO BE VERTICALLY ALIGnED.

Drill 9/32” diameter holes through the section at each marked location. Enlarge the holes

from outside the door to 1/2” diameter through the section. Assemble the outside and inside

lift handles to the section using (2) 1/4” x 2-1/2” carriage bolts and (2) 1/4”-20 hex nuts and

spacers.

WARNING

WARNING

TO AvOID POssIBLE INjuRy, LIfT hANDLEs ThAT ARE INsTALLED WIThIN

4 INChEs (102MM) Of A sECTION INTERfACE shALL PROMOTE vERTICAL

ORIENTATION Of ThE hAND.

(2) Spacers

1/2” Diameter holes

(2) 1/4” x 2-1/2” Carriage bolts

Lift handle

Lock section

outside

Lock section

inside

4”

Lift handle

(2) 1/4”-20 hex nuts

step Plate

5

Tools: Power drill, 7/16” Drill bit, Phillips screwdriver, Tape measure

On the bottom door section, locate the vertical center of the door.

On the inside of the door, center the inside step plate’s second top most hole and bottom

hole vertically over the pre-punched holes in the bottom section no higher than 8” from the

bottom of the door to the top of the step plate. Drill 7/16” diameter holes through the entire

section at these hole locations. Be careful to keep drill straight.

IMPORTANT: Do noT MounT THe STeP PLATe HigHeR THAn 8” fRoM BoTToM of Sec-

TIOn.

Insert the outside step plate into the holes through the front of the door, and mount the two

step plates back to back with two no. 8 x 1-1/2” screws through the inside step plate and

into the outside step plate.

Outside step plate

Bottom section outside

Holes enlarged

to 7/16” diameter

Inside step plate

Bottom section inside

Pre-punched

holes

(2) #8 x 1-1/2” screws

8” Max.

mounting

height

Bottom section

6

Tools: Level, Wooden shims (if necessary)

Center the bottom section in the door opening. Level the section using wooden shims (if

necessary) under the bottom section.

Weather seal

Level

Bottom section

Wooden shims

(If necessary)

vertical Track Assemblies

7

Tools: Power Drill, 3/16” Drill bit, 7/16” Socket driver, Tape measure,

Level, Step ladder

IMPORTANT: THE TOPS Of THE VERTICAL TRACKS MuST BE LEVEL fROM SIDE TO SIDE.

If THE BOTTOM SECTIOn WAS SHIMMED TO LEVEL IT, THE VERTICAL TRACK On THE

SHIMMED SIDE MuST BE RAISED THE HEIGHT Of THE SHIM.

Position the left hand vertical track assembly over the rollers of the bottom section. Make

sure the counterbalance cable is located between the rollers and the door jamb. Drill 3/16”

pilot holes into the door jamb for the lag screws.

Loosely fasten vertical track assembly to the jamb using 5/16” x 1-5/8” lag screws. Tighten

the bottom lag screw to jamb, to maintain 3/8” to 5/8” spacing as shown between the bot-

tom section and vertical track. The other lag screws will be tightened in step, Top Section.

Repeat for other side.

7