Warning, Securing door for spring winding, Winding springs – Wayne-Dalton 8300 User Manual

Page 11: Rear support

Please Do not Return This Product To The Store. Contact your local Wayne-Dalton dealer. To find your local Wayne-Dalton dealer,

refer to your local yellow pages business listings or go to the find a Dealer section online at www.wayne-dalton.com

securing Door for spring Winding

19

Tools: Vice Clamps

Place vice clamps onto both vertical tracks just above the third roller. This is to prevent the

garage door from rising while winding counterbalance springs.

WARNING

WARNING

fAILuRE TO PLACE vICE CLAMPs ONTO vERTICAL TRACk CAN ALLOW

DOOR TO RAIsE AND CAusE sEvERE OR fATAL INjuRy.

Vice clamps above third

roller on both sides of door

Bottom section

Vice clamps attached to inner

and outer rail of vertical track

Winding springs

20

Tools: Step Ladder, Approved winding bars, 3/8” Wrench

Position a ladder slightly to the side of the spring so that the winding cone is easily acces-

sible, and so your body is not directly in line with the winding bars.

Check the label attached to the spring warning tag for the required number of complete turns

to balance your door.

Door height

Approximate spring Turns

8’3”

8-7/8 Turns

8’6”

9-1/8 Turns

8’9”

9-3/8 Turns

9’0”

9-5/8 Turns

9’3”

9-3/4 Turns

9’6”

10 Turns

9’9”

10-1/4 Turns

10’0”

10-1/2 Turns

10’3”

10-3/4 Turns

10’6”

11 Turns

10’9”

11-1/8 Turns

11’

11-3/8 Turns

11’3”

11-5/8 Turns

11’6”

11-7/8 Turns

11’9”

12-1/8 Turns

12’0”

12-3/8 Turns

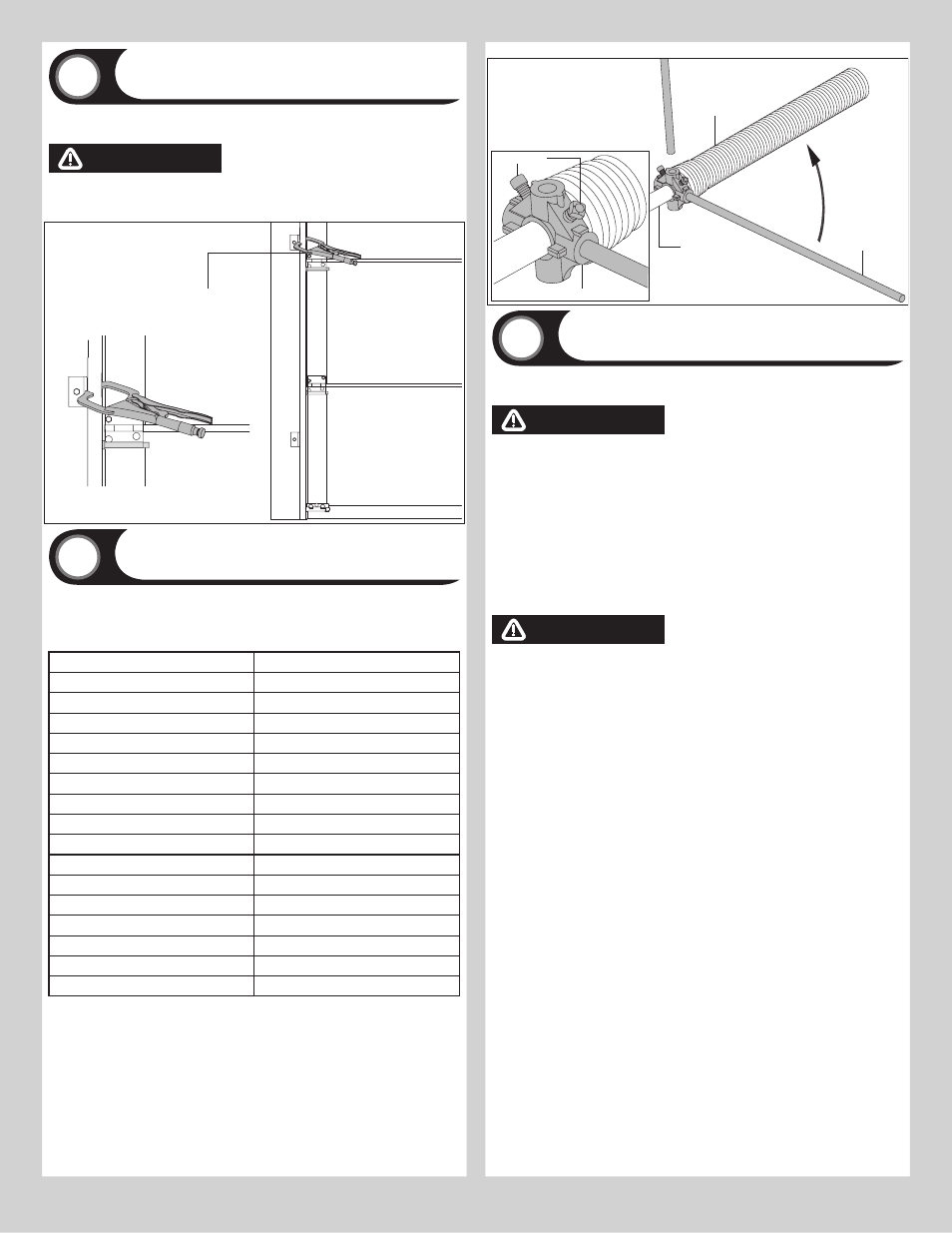

Alternately inserting the winding bars into the holes of the springs winding cone, rotate

the winding cone upward toward the ceiling, 1/4 turn at a time, until the required number

of complete turns for your door height is achieved. As the last 1/8 to 1/4 turn is achieved,

securely hold the winding bar while tightening both set screws in the winding cone to 14-15

ft. lbs. of torque (once set screws contact the tube, tighten screws one full turn).

Carefully remove winding bar from winding cone. Repeat for the opposite spring. While

holding the door down to prevent it from raising unexpectedly in the event the spring(s) were

over-wound, carefully remove the locking pliers from the torsion tube and vertical tracks.

Adjustments to the number of turns stated may be necessary. If door rises off floor under

spring tension alone, reduce spring tension until door rests on the floor. If the door is hard to

raise or drifts down on its own, add spring tension.

NOTE: An unbalanced door such as this can cause garage door opener operation problems.

Torsion tube

Winding cone

Spring

Approved

winding bars

Set screws

Rear support

21

Tools: Ratchet wrench, Socket: 1/2” 5/8”, Wrench: 1/2” 5/8”, (2) Vice

clamps, Tape measure, Level, Hammer, Step Ladder

Raise the door until the top section and half of the next section are in a horizontal position.

Do not raise door any further since rear of horizontal track is not yet supported.

WARNING

WARNING

RAIsING DOOR fuRThER CAN REsuLT IN DOOR fALLING AND CAusE

sEvERE OR fATAL INjuRy.

Clamp a pair of vice clamps on the vertical tracks just above the second roller on one side,

and just below the second roller on the other side. This will prevent the door from raising or

lowering while installing the rear support.

using perforated angle (may not be supplied), (2) 5/16”-1- 5/8” hex head lag screws and (3)

5/16” bolts with nuts (may not be supplied), fabricate rear support for horizontal tracks. At-

tach horizontal tracks to the rear supports with 5/16”-18 x 1 hex bolts and nuts (may not be

supplied). Horizontal tracks must be level and parallel with door within 3/4” to 7/8” maximum

of door edge.

NOTE: If an idrive

®

opener is installed, position horizontal tracks one hole above level when

securing it to the rear supports.

WARNING

WARNING

kEEP hORIzONTAL TRACk PARALLEL AND WIThIN 3/4” TO 7/8” MAxIMuM

Of DOOR EDGE, OThERWIsE DOOR COuLD fALL, REsuLTING IN sEvERE OR

fATAL INjuRy.

IMPORTANT: DO nOT SuPPORT THE WEIGHT Of THE DOOR On AnY PART Of THE HORI-

ZOnTAL TRACK HAnGER THAT CAnTILEVERS 4” OR MORE BEYOnD A SOunD fRAMInG

MEMBER.

NOTE: If rear supports are to be installed over drywall, use (2) 5/16” x 2” hex head lag

screws and make sure lag screws engage solid structural lumber.

NOTE: 26” angle must be attached to sound framing members and nails should not be used.

now, permanently attach the weather seal on both door jambs and header (temporarily at-

tached in Preparing the Opening, in the pre-installation section of this manual). Avoid pushing

weather seal too tightly against face of door.

11