Warning, Installation, Bottom brackets and counterbalance – Wayne-Dalton 8300 User Manual

Page 5: Hinge attachment, U-bars

InsTallaTIon

Before installing your door, be certain that you have read and followed all of the instruc-

tions covered in the pre-installation section of this manual. failure to do so may result in an

improperly installed door.

Bottom Brackets and Counterbalance

1

Tools: Power drill, 7/16” Socket driver

NOTE: Refer to door section identification, located in the pre-installation section of this

manual.

NOTE: Cable drums and bottom brackets are marked right and left hand.

WARNING

WARNING

fAILuRE TO ENsuRE TIGhT fIT Of CABLE LOOP OvER MILfORD PIN COuLD

REsuLT IN CABLE COMING Off ThE PIN, ALLOWING ThE DOOR TO fALL,

POssIBLy REsuLTING IN sEvERE OR fATAL INjuRy.

Attach left hand bottom bracket to the left corner of the bottom section, making sure it is

seated to the edges of the end cap, with (5) 1/4”-14 x 7/8” self drilling screws.

uncoil the counterbalance cables from the drums, making sure you place the left hand cable

loop on the left hand milford pin of the bottom bracket.

NOTE: Check to ensure cable loop fits tightly over the milford pin.

Insert a roller into spacer and the bottom bracket.

Repeat for other side.

NOTE: Verify astragal (bottom seal) is aligned with door section. If there is more than 1/2”

excess astragal on either side, trim astragal even with door section.

Counterbalance

cable loop

(5) 1/4”-14 x 7/8”

Self drilling screws

Bottom section

Roller

Milford pin

Bottom

bracket

End cap

Spacer

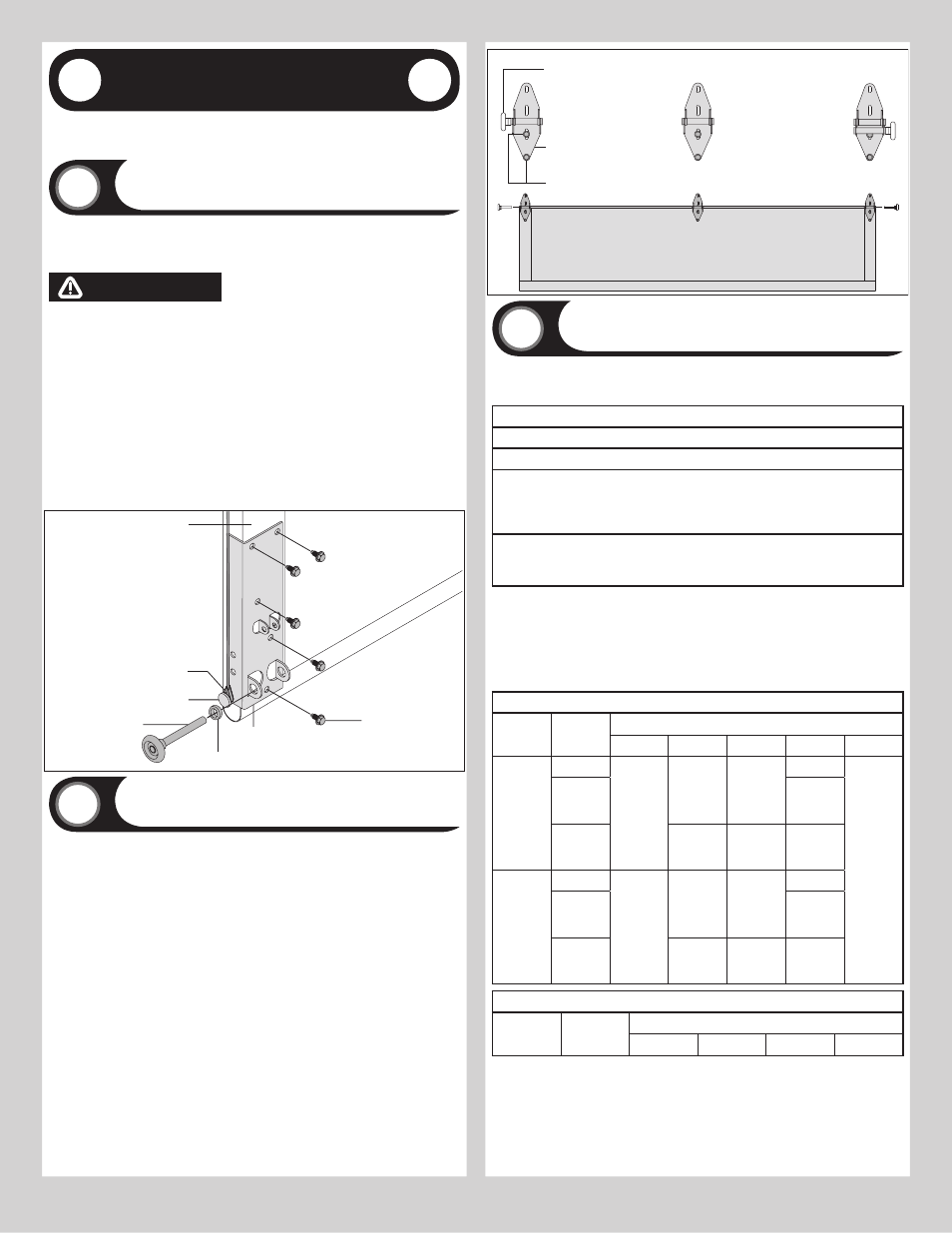

hinge Attachment

2

Tools: Power drill,7/16” Socket driver

NOTE: Refer to door section identification.

NOTE: Hinges can be identified by the number stamped onto their lower leaf.

Align the lower leafs of the #1 end hinges over the holes at the top of the end caps of the

bottom section, and align the lower leafs of the #1 intermediate hinges with the dimples

at the intermediate locations at the top of the section. Attach lower leafs to section with (2)

1/4”-14 x 7/8” Self drilling screws.

IMPORTANT: PuSH & HOLD THE HInGE LEAf SECuRELY AGAInST THE SECTIOn WHILE

SecuRing WiTH 1/4”-14 x 7/8” SeLf DRiLLing ScReWS. THeRe SHouLD Be no gAP

BETWEEn THE HInGE LEAf AnD THE SECTIOn.

Place a roller into each end hinge.

Repeat hinge attachment for all remaining sections except the top section, using #2 end

hinges for the lock section, #3 end hinges for the intermediate section, and #4 end hinges

for the intermediate II section, if such a section was provided.

#1Intermediate

hinge(s)

#1 End hinge

Roller

Lower leaf

#2 End hinge

(roller inserted into tube

furthest from section)

(2) 1/4”-14 x 7/8” Self

drilling screw locations

u-bars

3

Tools: Power drill, 7/16” Socket driver, Tape measure

NOTE: Refer to the u-bar schedules to determine the placement of u-bars on your door. Be

sure to use the schedules for Aluminum doors or Steel doors depending on the material your

door is made of. Also use the schedule for the proper color of your door.

schedule key:

2 = 2” u-bar, 3 = 3” u-bar

* = top of the section, ~ = across lower leaf of hinges and attached with strut clips

B = bottom section, L = lock section or second section, x = intermediate section #1 or

third section, Y = intermediate section #2 or fourth section of five section door, Z= inter-

mediate section #3 or fifth section of a six section door, T = top section,

W = windowed intermediate section, E = every section

for example: 3*B, means a 3” u-bar is attached at the top of the bottom section

2~x, means a 2” u-bar is placed across the lower leaf hinges and attached with strut

clips to intermediate section #1.

To attach a u-bar along the top of a section: Place u-bar against top of section and

align it horizontally with section. Attach to section using (2) 1/4”-20 x 7/8” self drilling screws

at each end and center stile location.

To attach a u-bar across the lower leaf of hinges with strut clips: Remove 1/4”-20

x 7/8” self drilling screws from lower leaf of hinges along sections which a u-bar will be

attached to. Place u-bar above across hinges and attach to section with strut clips and the

1/4”-20 x 7/8” self drilling screws which were removed.

8300 LT-coM Aluminum Strutting Schedule---White, Almond, and Taupe colored Doors

Section

quantity

Configu-

ration

Door Width

6’-9’

10’-14’

15’-16’

17’-18’

20’

5

Solid

2*T

2*T

2*T, 2~Y,

2*x, 2*B

2*E

n/A

Windows-

Top

3*T, 2*Y,

2*x, 2*L,

2*B

Windows-

Intermedi-

ate

2*T, 2~W

2*T, 2~W,

2*x, 2*B

2*E

6

Solid

2*T

2*T

2*T, 2~Y,

2*x, 2*B

2*E

Windows-

Top

3*T, 2*Z,

2*Y, 2*x,

2*L, 2*B

Windows-

Intermedi-

ate

2*T, 2~W

2*T, 2~W,

2*x, 2*B

2*E

8300 LT-coM Aluminum Strutting Schedule---Brown colored Doors

Section

quantity

Configura-

tion

Door Width

6’-10’

12’-16’

17’-18’

20’

Please Do not Return This Product To The Store. Contact your local Wayne-Dalton dealer. To find your local Wayne-Dalton dealer,

refer to your local yellow pages business listings or go to the find a Dealer section online at www.wayne-dalton.com

5