2 lateral analysis report (optional) – Taurus Group 60 User Manual

Page 73

Turbomachinery Package Specification

Taurus

60 Compressor Set and Mechanical Drive

If a resonance condition (interference) is found, then a fatigue analysis is performed to

confirm the resonance will not cause fatigue failure in the shafting.

18.5.2 Lateral Analysis Report (Optional)

A lateral forced response analysis of the driven equipment can be performed to confirm

that any lateral critical speeds aren’t close enough to the operating speed range to cause

lateral vibration problems.

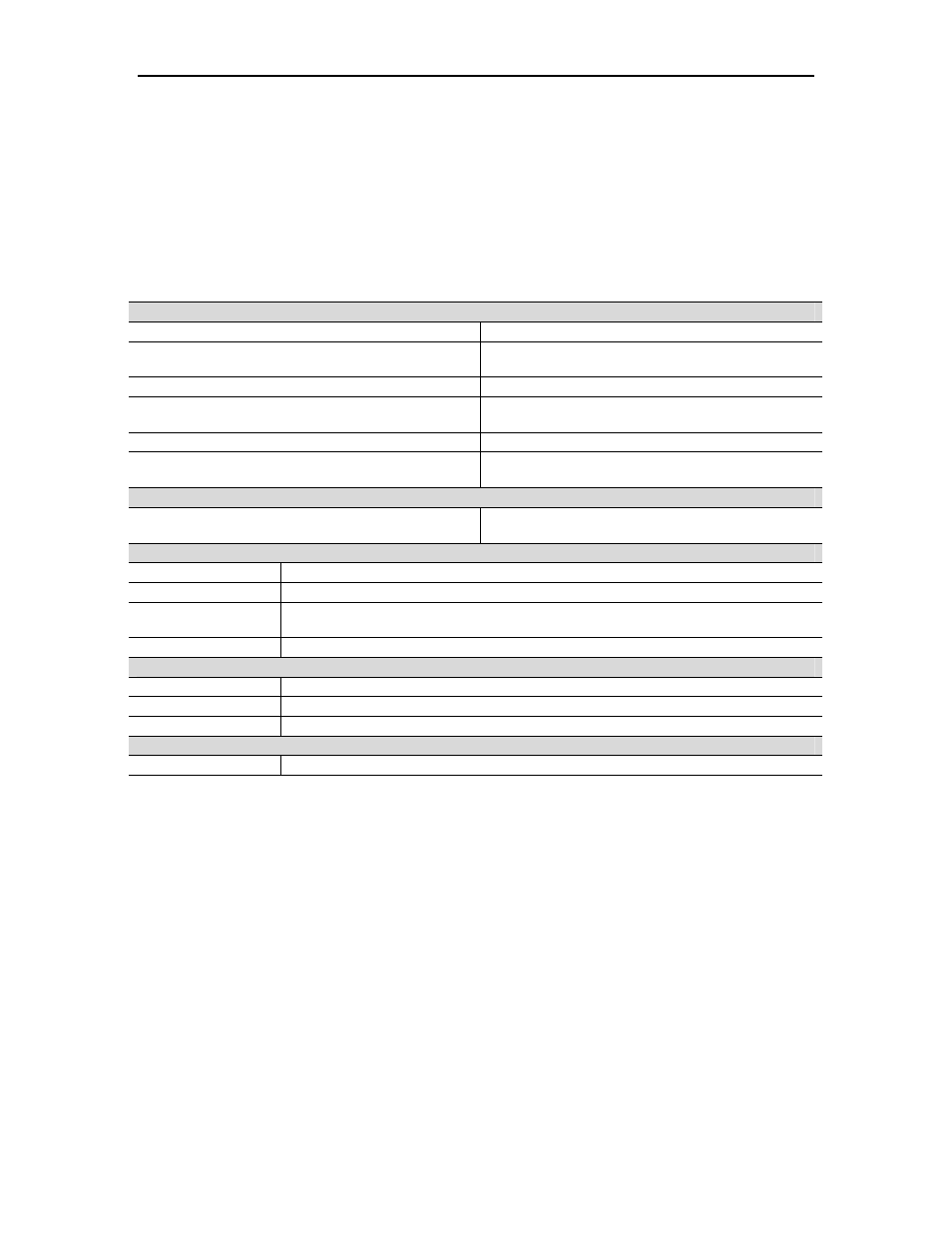

Table 15. Preservation, Installation, and Documentation Specifications

Mechanical Installation Requirements

Mounting

Space Between Units In Multiple-Unit

Installations

A Minimum of 2.4 m (8 ft)

Lube Oil Cooler(s)

Top of The Lube Oil Cooler(s)

Not Be More Than 9.1 m (30 ft) Above The Bottom

of The Package Frame, See Note a

Total oil volume of “Outgoing and Return” Lines

1282 L (340 gal)

Total Combined Pressure Drop of The Supply

and Return Lines and Lube Oil Cooler(s)

Should Not Exceed 345 kPag (50 psig)

Start, Fuel, Lube, Air/Drain System Schematics

Compliance

American National Standards Institute (ANSI)

Y32.10

Solar’s Applicable Engineering Specifications

ES 9-4

Interpretation of Drawing Requirements

ES 9-76

Traceability Requirements Critical Parts, Engine and Related Systems

ES 2231

Standards and Practices for The Design and Installation of Cable Channels and

TC Rated Cables Installed In Class 1, Division 2 Hazardous Areas

ES 9-414

Leveling and Installing of Package Bases

Solar’s Applicable Product Information Letters

PIL 097

Package Preservation and Preparation for Shipment

PIL 181

Package Tie-down Options

PIL 184

Order Fulfillment & Documentation for Oil & Gas Projects

Solar’s Applicable Guidelines

TPIM-1010

Package Installation Guidelines – Compressor Sets and Mechanical Drives

Notes

:

(a)

This is to prevent oil tank flooding in the event of a drain back.

© 2009 Solar Turbines Incorporated. All rights reserved.

TPS60CSMD/309

72