7 hydrostatic testing, 8 shaft coupling, 9 preliminary alignment – Taurus Group 60 User Manual

Page 18

Turbomachinery Package Specification

Taurus

60 Compressor Set and Mechanical Drive

4.2.7 Hydrostatic

Testing

Hydrostatic pressure testing of all compressor casings and end caps is done per API 617

for 30 minutes at 1.5 times the maximum casing design pressure, regardless of

application.

Test water is treated with a wetting agent to allow better penetration of

possible casing defects. After the hydro and final magnetic particle test, the casing is

steam cleaned and bead blasted for surface preparation. Afterwards, it is painted per

Solar’s specification ES 9-58.

4.2.8 Shaft

Coupling

Solar’s standard shaft interconnect is a Kop-Flex dry coupling.

4.2.9 Preliminary

Alignment

The drive train is aligned preliminarily at the factory to simplify final field alignment.

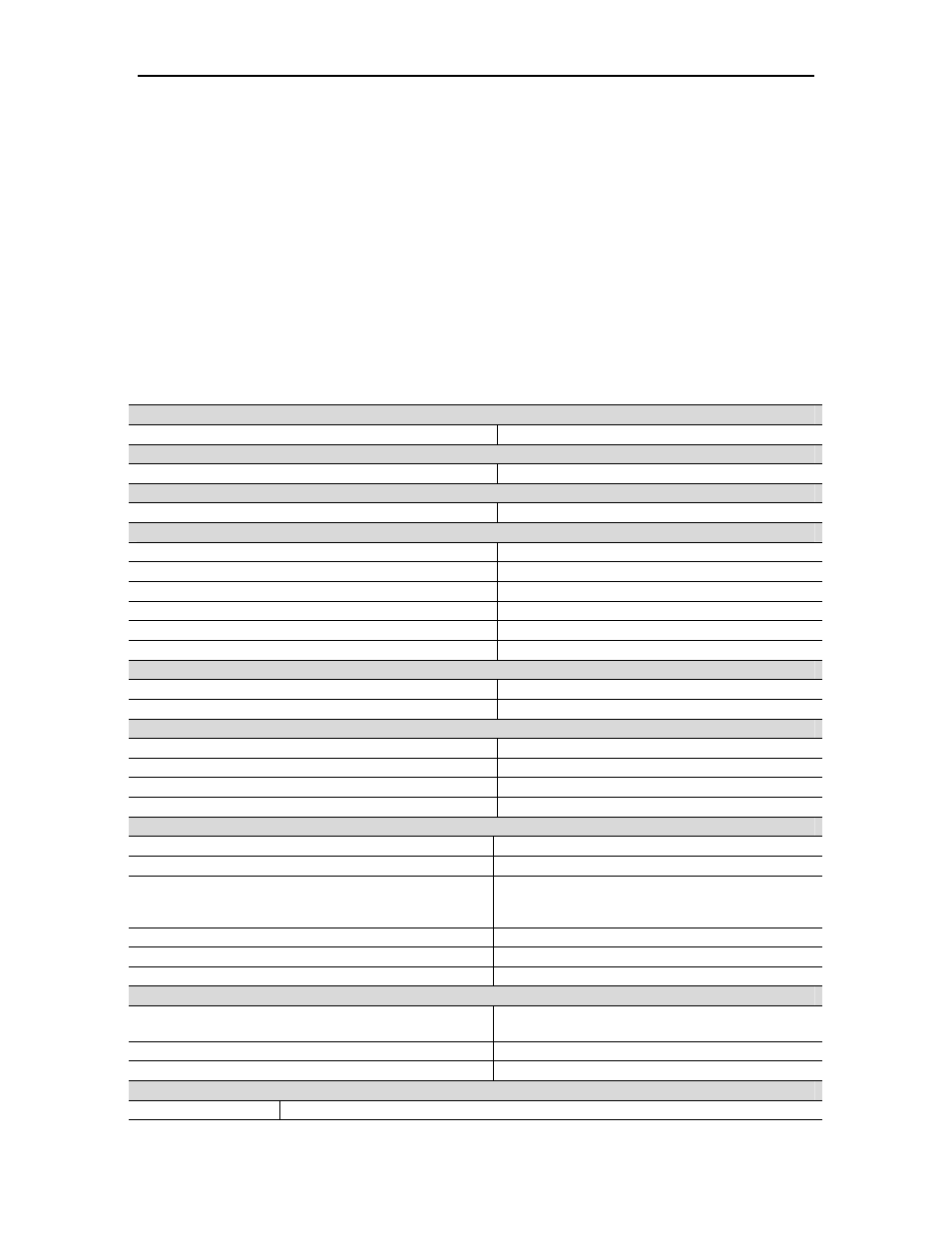

Table 4.

Driven Equipment and Associated Equipment Specifications

Typical Driven Skid Weight

One to Three Compressor Bodies

6800 to 34 000 kg (15,000 to 75,000 lb)

Typical Driven Skid Lengths

One to Three Compressor Bodies

4.0 to 10 m (13 to 33 ft)

Compressor Inspection Interval

Major Inspection Interval

Three Years of Continuous Full-Load Duty

Compressor Construction Materials

Impeller 15-5PH,

Type

100

Casing

ASTM A216 GR WCC

Diaphragm/Guide Vane

Alloy Steel

Rotor Spacer

Alloy Steel

Stub Shafts

AISI 4140

Labyrinth Steel-Backed

Babbitt

Compressor Bearings

Journal Bearing

Tilting Pad

Thrust Bearing

Self Aligning, Tilting Pad

Compressor Vibration Monitoring

Driver End Bearing

Displacement Probes, X and Y Axis

Driven End Bearing

Displacement Probes, X and Y Axis

Thrust Bearing

Displacement Probe, Axial

Compressor Rotor Shaft Keyphasor

Seal Gas

Fluid

Clean Process Gas or Nitrogen

Particle Size

Less Than 2 micron

Minimum Supply Pressure

689 kPag (100 psig) above highest compressor

suction pressure but below pressure rating of

seal system

Maximum Supply Pressure

13 790 kPag (2000 psig)

Flow

1.3 to 3.3 nm

3

/min (50 to 125 SCFM)

Temperature

0 to 93°C (32 to 200°F)

Separation Gas

Air Quality

Refer to Solar Engineering Specification ES

2201

Supply Pressure

517 to 1344 kPag (75 to 195 psig)

Flow 0.134

nm

3

/min (5 SCFM)

Solar’s Applicable Engineering Specifications

ES 9-58

Standard Paint Program - Turbomachinery

© 2009 Solar Turbines Incorporated. All rights reserved.

TPS60CSMD/309

17