Component operation – Taurus Group 60 User Manual

Page 28

Turbomachinery Package Specification

Taurus

60 Compressor Set and Mechanical Drive

• Pilot air operated secondary gas fuel shutoff valve

• Pilot air operated gas vent valve

• Electrically operated fuel control valve

• Torch with shutoff valve and pressure regulators

• Main fuel manifold

• Fuel injectors

For SoLoNOx combustion, the fuel system also includes:

• Fuel pilot control valve

• Fuel pilot manifold

• Inlet gas filter/coalescer loose shipped for field installation

Component Operation

The gas fuel pressure supplied to the turbine skid must meet minimum and maximum

pressure and flow requirements. If the gas fuel pressure is too high or too low, the control

system will prevent turbine operation. Pneumatically actuated primary and secondary gas

fuel shutoff valves are controlled using pilot air pressure. For each valve, pilot air

pressure is admitted to and exhausted from a pneumatic actuator through a solenoid

valve. Fail-safe operation ensures both valves will close in case pilot air pressure is lost.

The gas fuel control valve and, when applicable, the SoLoNOx fuel pilot control valve, are

powered by integrated DC motor-driven actuators. Integrated actuator electronics provide

precise closed-loop valve control based on position command inputs versus position

feedback outputs. Both valves are fast acting and provide fuel metering for light-off,

acceleration, full load, and load transient conditions. Fail-safe operation ensures both

valves will close in case the command signal or control power is lost. During the start

sequence prior to ignition, the control system will verify gas pressure and perform a gas

valve check to verify proper operation of all gas fuel valves.

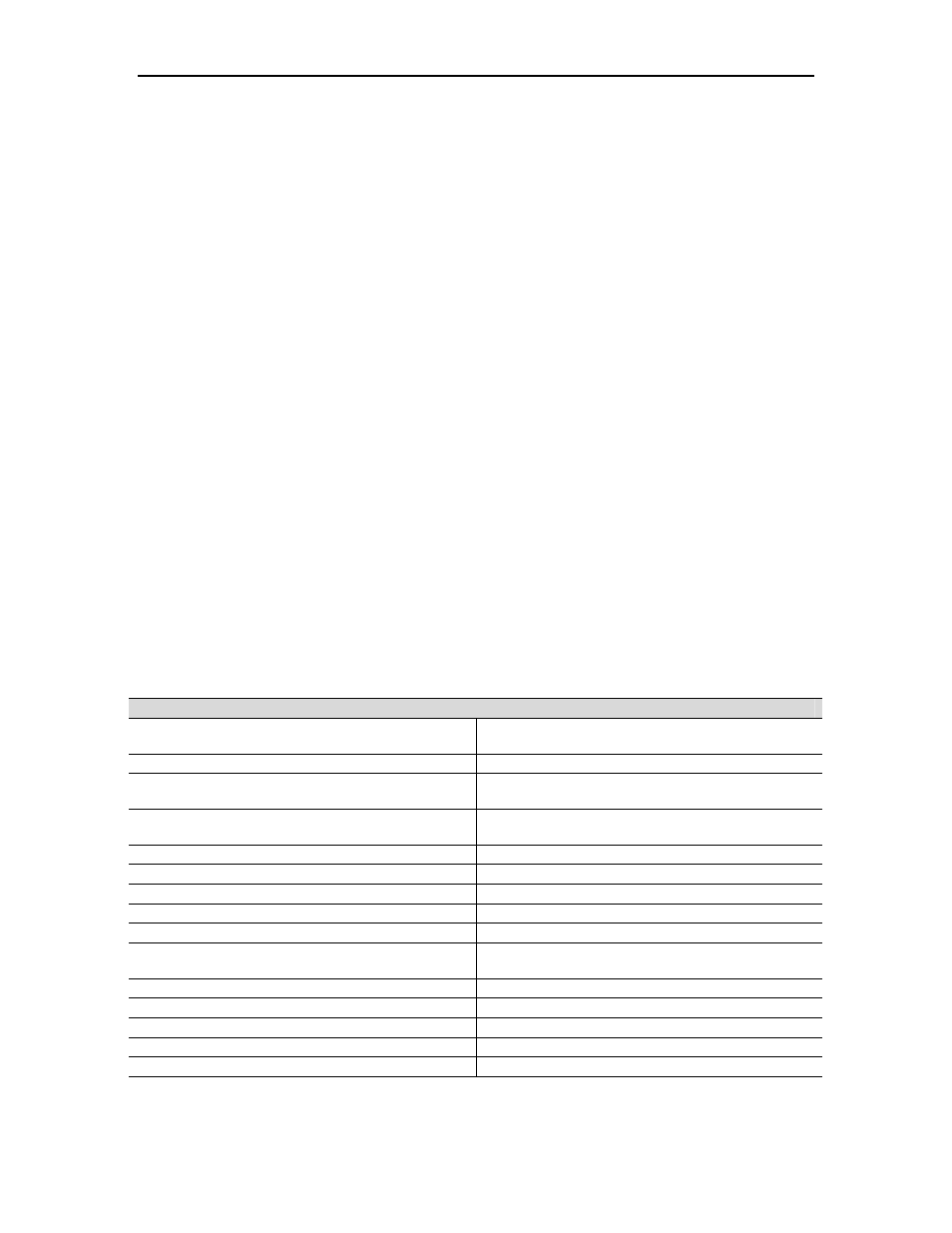

Table 8.

Fuel System Specifications

Gas Fuel System

Acceptable Gas Fuels See Note (a)

Natural Gas

Propane

Fuel Quality

Refer to Solar’s Engineering Specification ES 9-98

Optional Fuel System Types

Conventional Combustion or SoLoNOx

Combustion

Compliance

National Association of Corrosion Engineers

(NACE) Compliant

Minimum/Maximum Gas Fuel Supply Pressure

1170 to 2068 kPag (170 to 300 psig), See Note (b)

Minimum Flow Rate

1475 kg/hr (3250 lb

m

/hr), See Note (b)

Minimum/Maximum Fuel Supply Temperature

-40° to 93°C (-40° to 200°F), See Note (c)

Primary Gas Fuel Shutoff Valve

Pneumatically Actuated Spring-Closed Ball Valve

Secondary Gas Fuel Shutoff Valve

Pneumatically Actuated Vane Type Valve

Gas Fuel Control Valve and SoLoNOx Fuel Pilot

Control Valve (If Applicable)

Actuator Valve

Actuator Voltage

120 VDC

Valve Discrete Signals

24 VDC

Valve Analog Signals

4 to 20 mA

Maximum Operating Pressure

1380 kPag (200 psig)

Maximum Operating Temperature

93°C (200°F)

© 2009 Solar Turbines Incorporated. All rights reserved.

TPS60CSMD/309

27