Maintenance bearing installation – Tiger Products Co., Ltd JD 72-7520 User Manual

Page 82

Maintenance Section 4-20

MAINTENANCE

BEARING INSTALLATION

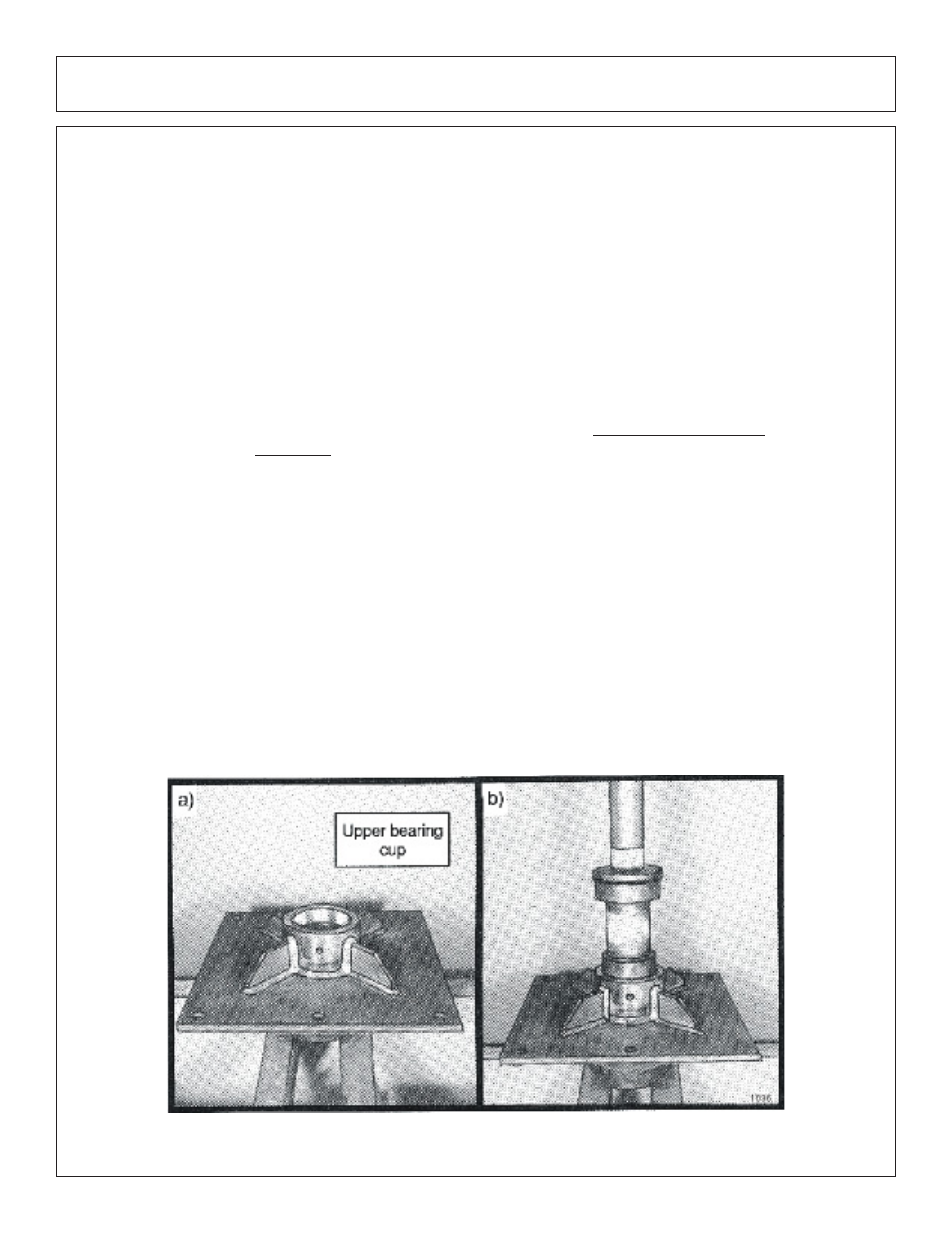

1 – Press upper bearing cup into the spindle housing.

2 – Turn the spindle housing over and press in the lower bearing cup.

3 – Place the lower bearing cone in the bearing cup. Next press the seal into the

spindle housing. The inner lip of the seal must be DOWN, towards the bearing, so

lubricant is sealed inside the housing.

4 – Install the spindle in the housing. Lightly tap the end of the spindle with a soft

faced hammer to seat the spindle against the bearing inner race.

5 – Turn the spindle housing over (up position) and fill with Tiger Spindle Lubricant

(part number 06540000) to the top edge of the upper bearing cup.

6 – Support the bottom of the spindle and press the upper bearing cone and bearing

adjustment sleeve onto the spindle.

NOTE: The spindle housing must turn freely when seating the

bearing cone and sleeve.

7 – Press the two upper seals into the spindle housing. The inner lip of the seals

must be UP, away from the bearing, so excess lubricant can escape.

8 – Install the bearing adjustment nut (thin nut) so there is 1/16” clearance between

the nut and the sleeve. Install the jam washer, placing the tab into the key-way.

Install the bearing lock nut (thin nut) and hand tighten against jam washer and

adjustment nut. See the following section for bearing adjustment.