Omega Vehicle Security LVP-51 Series User Manual

Page 14

14

MAINTENANCE

Step Seven

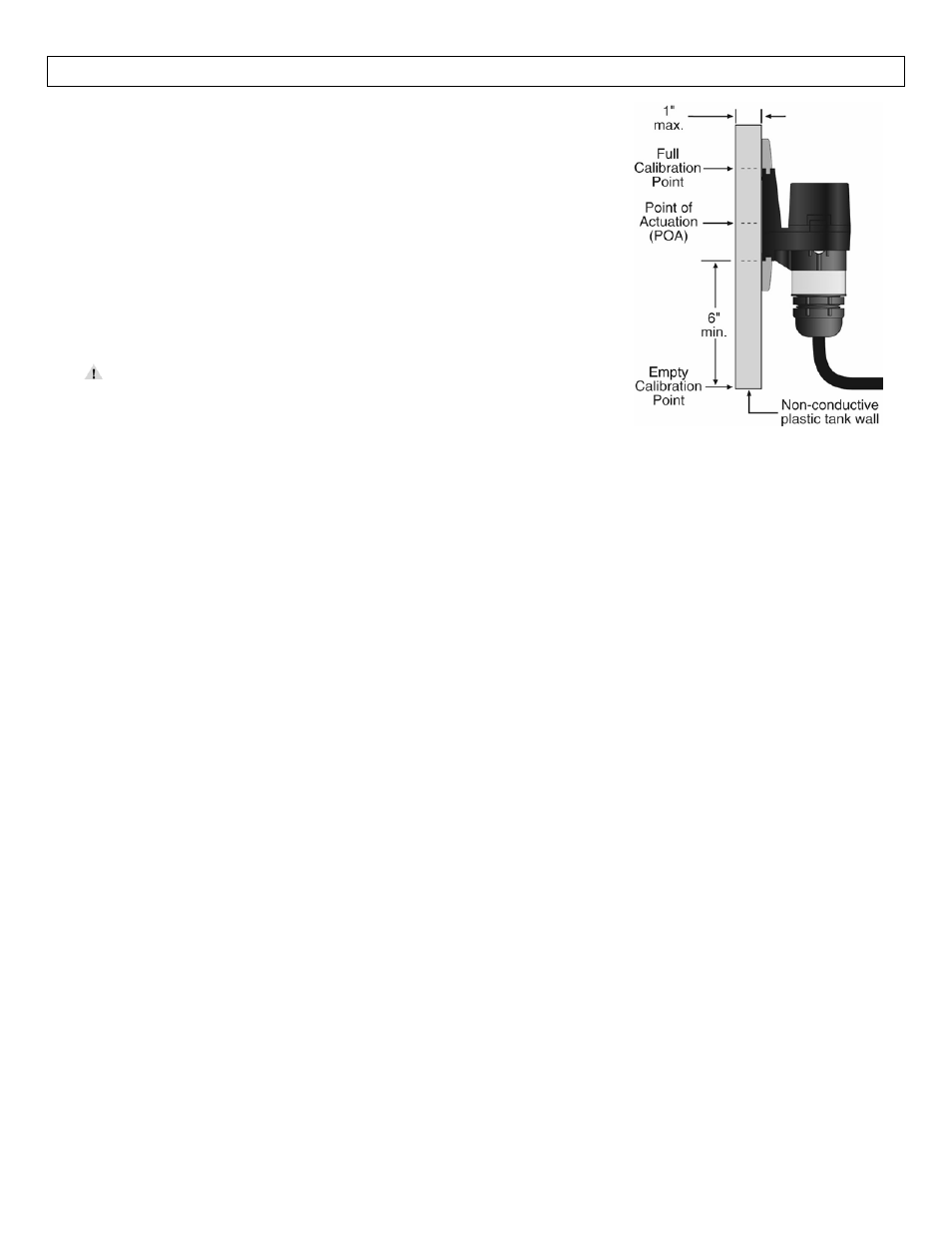

Checking the Point of Actuation: Raise the fluid level to the point

where the sensor sends a “wet” signal (Input LED will turn Amber on

OMEGA ENGINEERING controllers). The “dry” signal should be sent

when the fluid level is lowered (Input LED will turn Green on OMEGA

ENGINEERING controllers). The actual Point of Actuation (POA)

depends on many variables, including the thickness of the wall and the

dielectric value of the liquid. For example, thicker tank walls can raise

the POA while thinner walls could lower the POA.

If the POA needs to be changed, measure the distance and remount the

sensor in a new location.

Do not attempt to change the Point of Actuation by intentional

miscalibration.

If the sensor does not signal wet and dry reliably, it may be that:

the dielectric constant of the application fluid is too low

the tank wall is too thick for the application fluid

there are static or other electrical charges in the fluid

metal objects are within 6" of the sensor

calibration was performed incorrectly

Try the calibration procedure again, after making corrections if possible. If the full and empty states are too

similar dielectrically, it may not be possible to use a capacitance sensor.

Testing the Sensor:

1. Power: Apply power to sensor, by connecting power to the controller and/or power supply.

2. Full condition: Fill the tank with the application liquid, by filling the tank up to the sensor’s point of

actuation.

3. Test: With the sensor being fluctuated between wet and dry states, use a multimeter to ensure that

the correct signals are being produced by the LVP‐51‐R level switch, or observe the sensor indicator

light in the controller.

4. Point of Actuation: Observe the point at which the rising or falling fluid level causes the sensor to

change state, and move the installation of the sensor if necessary.

Maintenance: The LVP‐51‐R level switch itself requires no periodic maintenance except cleaning as required.

However, periodically clean any coating or scaling on the tank wall the sensor is attached to and check the

calibration. It is the responsibility of the user to determine the appropriate maintenance schedule, based on

the specific characteristics of the application liquids. In addition, any dripping or condensation between the

sensor and the tank wall fitting may need to be periodically cleaned to maintain accuracy.