Installation, Planning your fluing installation, Fluing – Regency FIREGENIE FG37-NG User Manual

Page 8: Fluing installation precautions, Safety precautions for the installer, Important

8

FG37 Regency Rear Flued Room Sealed Freestanding Gas Heater

PLANNING YOUR FLUING INSTALLATION

INSTALLATION

FLUING

The Regency Room Sealed System (Horizontal

Termination Kit (946-110) and the Vertical Ter-

mination with the Co-linear Flex System in

combination with the REGENCY Room Sealed-

Rear Freestanding Gas Stoves (FG37-NG and

FG37-LPG) have been approved and listed as

Room Sealed heater systems by Australian

Gas Association.

The Horiz. Termination Kit (946-110) includes

everything required for a straight through the

wall installation, or add a 45

o

elbow for a corner

installation.

IMPORTANT

Read all instructions carefully before starting

the installation. Failure to follow these instruc-

tions may create a fire or other safety hazard,

and will void the warranty. Be sure to check the

fluing and clearance to combustible require-

ments on pages 6 to 9. Consult your local

building codes before beginning installation.

The location of the termination cap must con-

form to the requirements in the Exterior Flue

Terminal Locations diagram on page 7.

FLUING

INSTALLATION

PRECAUTIONS

The Regency Room Sealed System and the

Vertical Termination with the Co-linear Flex

System are engineered products that have

been designed and tested for use with the

FG37-NG, and FG37-LPG. The Regency war-

ranty will be voided and serious fire, health or

other safety hazards may result from any of the

following actions:

1) Installation of any damaged Room Sealed

component

2) Unauthorized modification of the Room

Sealed System

3) Installation of any component part not man-

ufactured or approved by Regency Indus-

tries Ltd.

4) Installation other than as instructed by Re-

gency Industries Ltd.

Warning: Always maintain required

clearances (air spaces) to nearby

combustibles to prevent a fire haz-

ard. Do not fill air spaces with insu-

lation.

The minimum clearance requirements between

the outer wall of the flue pipe and nearby

combustible surfaces is 30mm. Be sure to

check the flue termination clearance require-

ments from decks, windows, soffits, gas reg-

ulators, air supply inlets and public walkways

as specified on page 7 and in your local building

codes.

The gas appliance and flue system

must be flued directly to the outside

of the building, and never be at-

tached to a chimney serving a sep-

arate solid fuel or gas-burning ap-

pliance.

Each Room Sealed gas appliance must use its

own separate flue system. Common flue sys-

tems are prohibited.

SAFETY

PRECAUTIONS FOR

THE INSTALLER

1) Wear gloves and safety glasses for pro-

tection.

2) Exercise extreme caution when using lad-

ders or on roof tops.

3) Be aware of electrical wiring locations in

walls and ceilings.

See page 7 for Exterior Flue Termination

requirements.

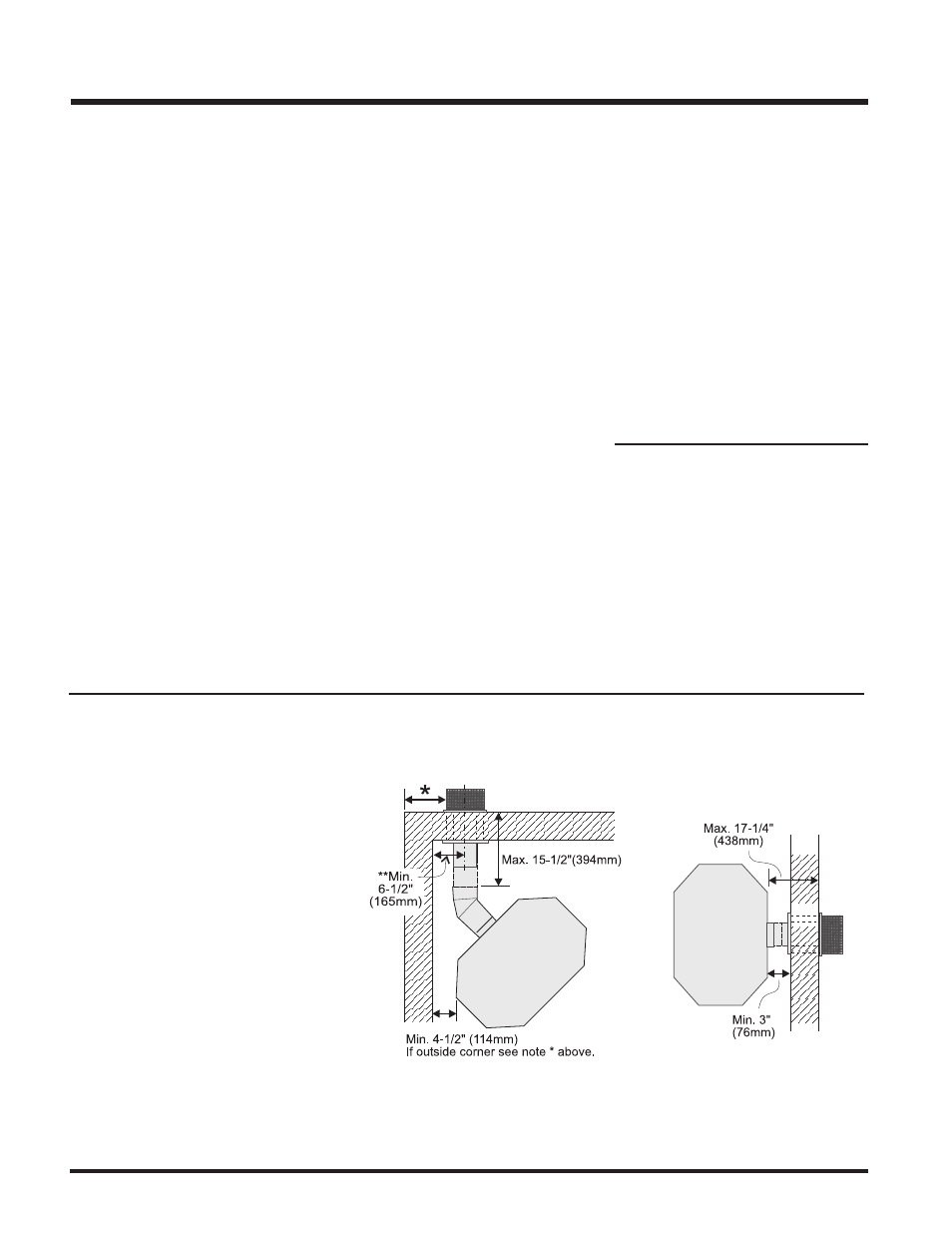

When planning your installation, it will be nec-

essary to select the proper length of flue pipe

for your particular requirements. Determine the

minimum clearance to combustibles from the

rear of the unit to the wall. It is also important to

note the wall thickness. Before cutting the flue

hole through the wall ensure that ALL flue and

termination clearances (see page 7) will be met.

*If this is an outside corner, the minimum distance between the flue and the outside corner

is 12" (30cm). See "F" on the diagram on page 7.

NOTE: Ensure compliance with the outside

flue terminal location before cutting hole as

both dimensions must be met.

For corner installation, Restrictor must

be set at 1-1/4" (32mm) open.

For straight rear installation, Restric-

tor must be set at 1-1/8" (29mm) open.