Raypak MVB 503-2003 User Manual

Page 44

44

gas pressure switch (if provided) must be set at

3.0 in. WC for natural gas and propane gas.

8. Make sure that the high gas pressure switch (op-

tional) is set to 3.0 in. WC for both natural gas and

propane gas.

Follow-Up

Safety checks must be recorded as performed.

Turn heater on. After main burner ignition:

1. Check manometer for proper readings.

2. Cycle heater several times and re-check readings.

3. Remove all manometers and replace caps and

screws.

4. Check for gas leaks one more time.

Leak Test Procedure: Dual-Seat Gas

Valve

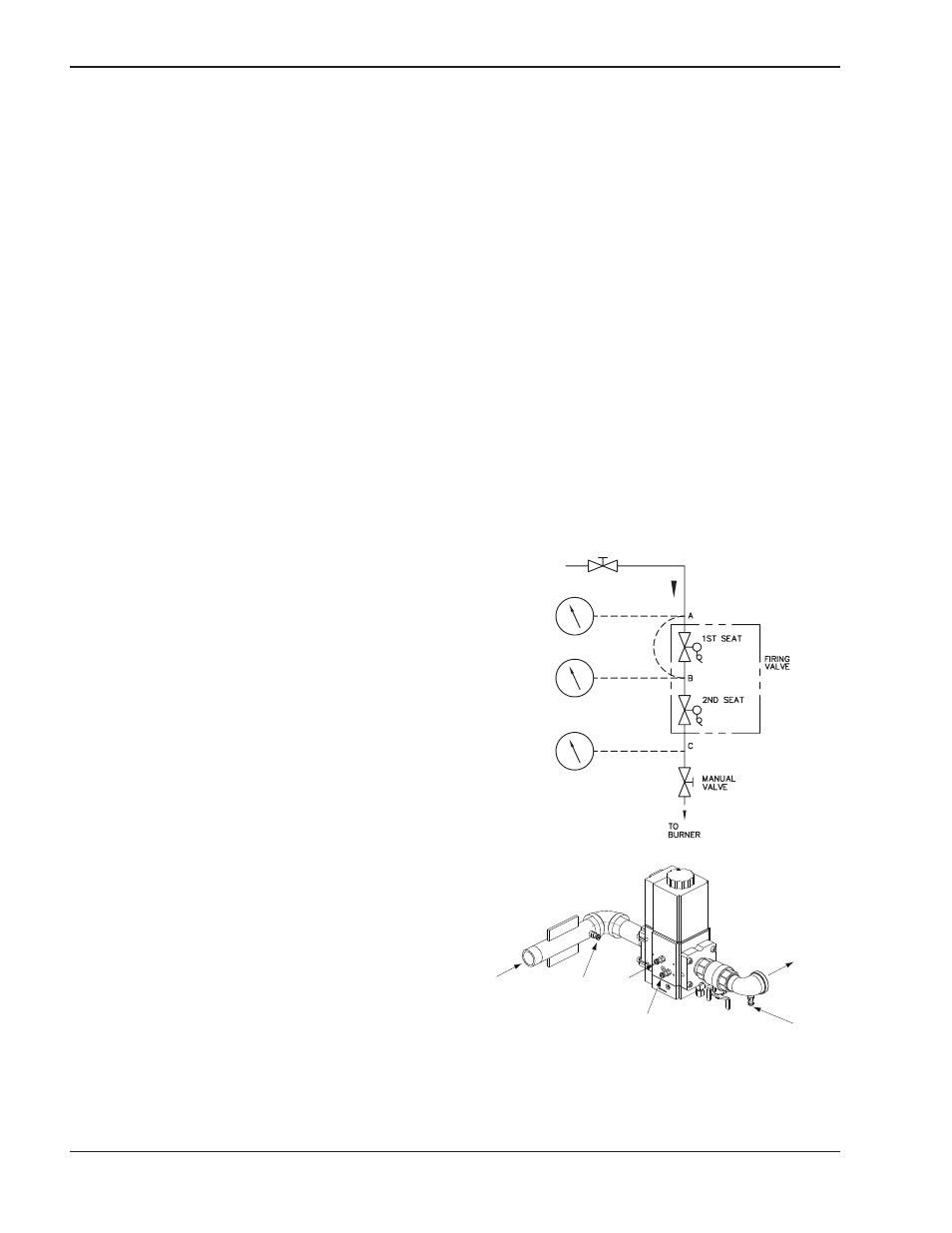

Proper leak testing requires three pressure test points

in the gas train.

Remove the access panel on the rear of the heater to

access the gas valve for this test. Test point A is a blee-

dle valve located upstream of the combination gas

valve on the supply manifold.

Test point B is a bleedle valve located between the two

automatic gas valve seats.

Test point C is a bleedle valve located downstream of

both automatic gas valve seats and upstream of the

manual valve. Refer to Fig. 48.

These tests are to be conducted with the electrical

power to the heater turned OFF.

1. Manually close the downstream leak test valve.

2. Open the bleedle valve at test point A and connect

a manometer to it. Verify that there is gas pressure

and that it is within the proper range (NOTE: must

not exceed 14.0 in. WC).

3. Open test point B and connect a rubber tube to it.

Connect the other end of the tube to a manometer

and look for a build-up of pressure. Increasing

pressure indicates a leaking gas valve which must

be replaced.

4. Next, close the upstream manual gas valve (field

supplied) and remove the manometers from the

bleedle valves in test point A and test point B.

Connect a rubber tube from the test point A blee-

dle valve to the test point B bleedle valve and

open the upstream manual gas valve. Make sure

that test point A & B bleedle valves have been

opened so as to allow gas to flow. This will bring

gas pressure to the second valve seat.

5. Open the bleedle valve at test point C and connect

a second rubber tube to it. Connect the other end

of the tube to a manometer and look for a build-up

of pressure. Increasing pressure indicates a leak-

ing gas valve which must be replaced.

6. Remove rubber tube and manometers. Close

each test point bleedle valve as the tubes are

removed.

7. After no leakage has been verified at all valve

seats and test valves, open downstream leak test

valve and restore electrical power to the heater.

Fig. 48: Leak Test Procedure

GAS

TO BURNER

A

B

C

D