Optional equipment, Cold water solutions, Multi boiler solutions – Raypak MVB 504 User Manual

Page 3: State of the art european combustion technology

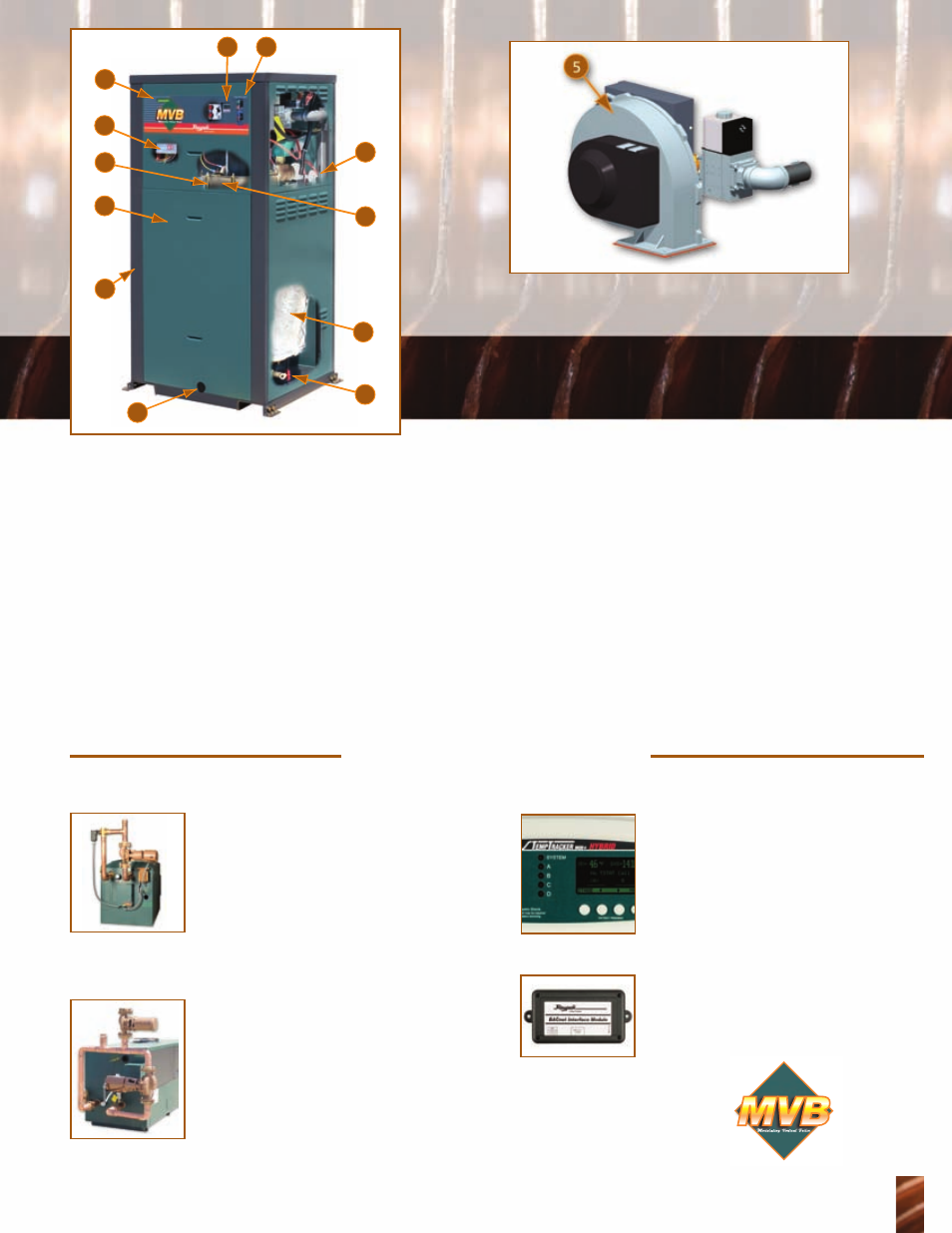

1. Control Panel

Fully enclosed controls and wiring protect against dam-

age or vandalism. Cabinet design affords easy access to

controls for installation and service.

2. Temp-Tracker Mod Control

This factory-mounted multi-function control

delivers precise load-tracking with selectable

mode displays that are easy to access and read.

3. On Board Diagnostic Center

Factory-mounted standard equipment. Gives relevant

service feedback as well as possible solutions to clear

the fault. All in plain English, no cryptic codes to deci-

pher. The control also stores up to 16 fault codes in its

history file for the service technician to review.

4. Weather-Proof Jacket

Heavy gauge galvanized steel with a UV-resistant

Polytuf powder coat finish is impervious to weather and

corrosion.

5. Combustion Air Fan

Cast aluminum, non-sparking construction.

6. Vent Pressure Switch

Monitors vent pressure and provides safe shut down if

back pressure is excessive.

7. Minimum Clearance Requirements

Only one inch of side clearance is required from

combustible surfaces.

8. Vertical Heat Exchanger

Cylindrical, multi-pass heat exchanger captures all radi-

ant energy, eliminating the need for heavy refractory.

9. Rugged Cast Headers

Bronze headers standard on water heater models. Cast-

iron standard on boiler models, with bronze headers

optional.

10. Tube Sheet Construction

Eliminates the repair & maintenance problems associat-

ed with rolled-tube construction. Easy, cost-effective

component replacement.

11. Viewing Port

Allows easy burner inspection.

12. Low Voltage Wiring Connections

Up front and easy to get to. Makes sensor wiring and

external control wiring simple and clean.

13. Drain Valves

Two drain valves located at the bottom of the heat

exchanger. This allows for complete winterizing and

drainage of the heater.

1

2

3

10

4

6

9

7

8

11

13

12

Cold Water Solutions

Cold Water Start – For applications that

require reliable protection against harmful con-

densation caused by frequent, extended, cold

water start-ups. Raypak’s Cold Water Start pro-

tection system utilizes a proportional three-

way valve to bypass water from the boiler out-

let to the inlet during start-up, when the sys-

tem return water temperature is below the minimum acceptable

level. (See Cat. #1000.19)

Cold Water Run – For applications requir-

ing constant condensation protection. Raypak’s

Cold Water Run system utilizes a variable-

speed pump to inject just the right amount of

water from the main system loop into the boil-

er to maintain the optimum inlet temperature.

This approach allows the full capacity of the

boiler to be utilized to meet the system load,

while at the same time continuously maintaining the optimum inlet

water temperature to prevent condensation. (See Cat. #1000.19)

Multi Boiler Solutions

State of the art European combustion technology

Optional Equipment

3

TempTracker Mod+ Hybrid– Controls up

to 16 Raypak boilers with PID logic. Automatic

or manually selectable lead-lag boiler opera-

tion. TempTracker Mod+ Hybrid monitors and

displays supply water temperatures on all

applications including outdoor temperature

when outdoor reset mode is selected. Can

also be used to control a mix of condensing

and non condensing boilers using our Hybrid

control algorithm. Now available with

optional BACnet

®

BMS link.

(See Cat. # 5100.22)

Hybrid Control

BACnet BMS Link