Troubleshooting – RIDGID TP1300 User Manual

Page 27

27

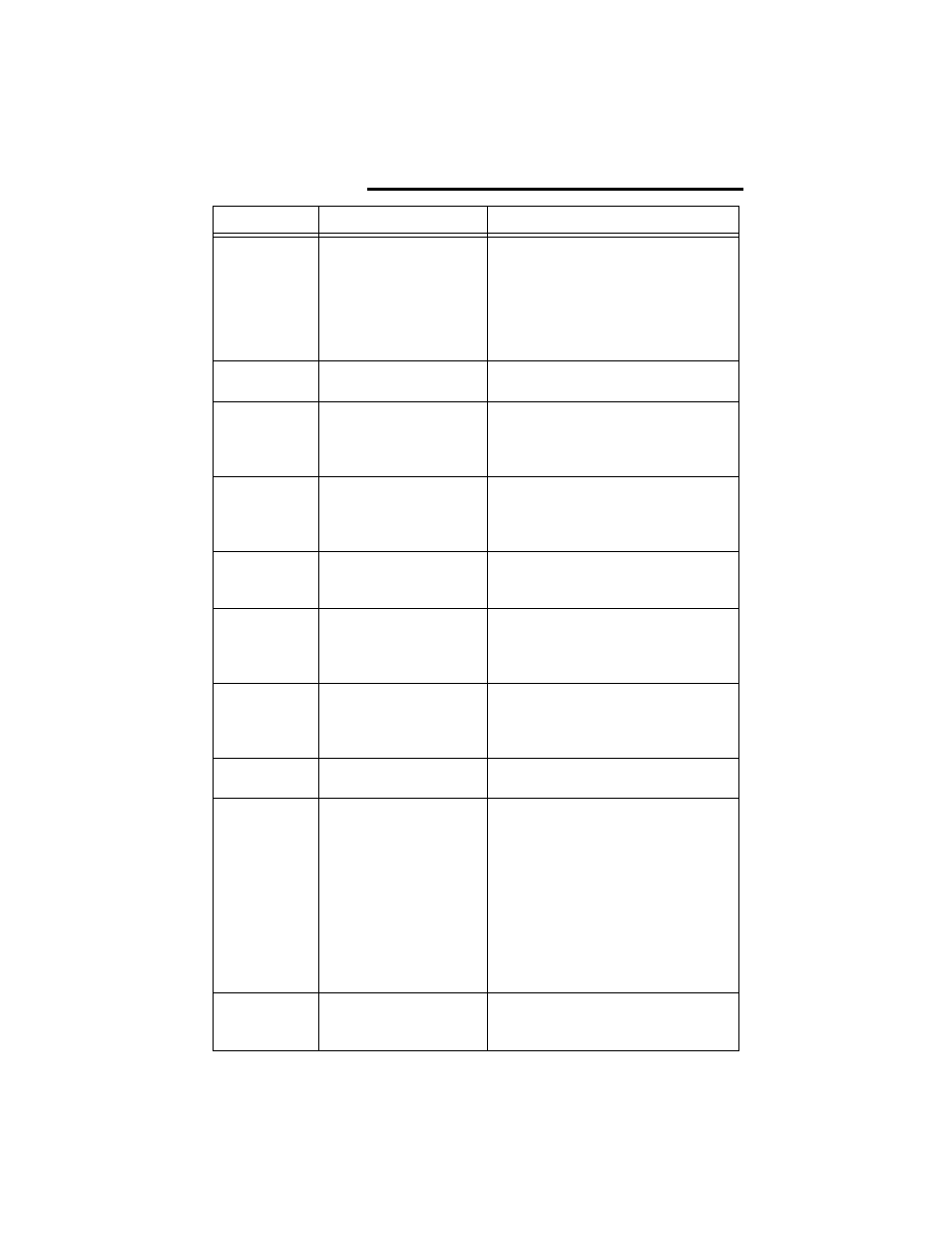

Troubleshooting

Problem

Possible Cause

Remedy

Snipe

(Gouging at

ends of board)

1. Dull knives

2. Inadequate support of

long boards

3. Lumber not butted

properly

4. Extensions misaligned

1. Replace knives per instructions (See

“Replacing Knives” section)

2. Support long boards

3. Butt end to end each piece of stock

as boards pass through planer

4. Adjust extension supports

Fuzzy Grain

1. Planing wood with a

high moisture content

1. Remove high moisture content from

wood by drying

Torn Grain

1. Too heavy a cut

2. Knives cutting against

grain

3. Dull knives

1. Review “Depth of Cut” section

2. Review “Feeding the Work” section

3. Replace knives per instructions

Rough Raised

Grain

1. Dull knives

2. Too heavy a cut

3. Moisture content too

high

1. Replace knives per instructions

2. Review “Depth of Cut”

3. Dry the wood or use dried wood

Uneven Depth

Cut Side to

Side

1. Blade projection not

uniform

1. Check that end of knife is fully

seated in the cutter head.

Cutter head

Elevation

Adjusts with

Difficulty

1. Elevation screws dirty

2. Gears or screws worn

3. Friction between cas-

ing and covers

1. Clean and lubricate elevation screws

2. Replace

3. Clean, lubricate

Board Thick-

ness Does Not

Match Depth of

Cut Scale

1. Indicator not set cor-

rectly

2. Knife projection incor-

rect

1. Adjust indicator/securely tighten

2. Set knife projection correctly (See

“Replacing Knives” section).

Chain Jumping 1. Sprockets worn

2. Chain worn

1. Replace sprockets

2. Replace chain

Motor does not

start

1. Switch malfunction

2. Overload protector

tripped

3. Supply fuse opens

4. Brushes worn

5. Other

1. Have a qualified electrician replace

the ON/OFF switch.

2. Turn power switch off. When planer

temperature adequately cools (allow

15-30 minutes) press overload pro-

tector reset button.

3. Replace fuse with a 15 amp time

delay fuse, or circuit breaker.

4. See “Maintenance” section, ”Chang-

ing Brushes

5. Get authorized service.

Dust chute is

blocked

1. Build up of resin under

dust chute

2. Large debris

1. Clean dust chute and exhaust area.

2. Clear debris.