Pid tuning in position mode – RoboteQ Dual Channel Digital Motor Controller AX500 User Manual

Page 71

AX500 Motor Controller User’s Manual

71

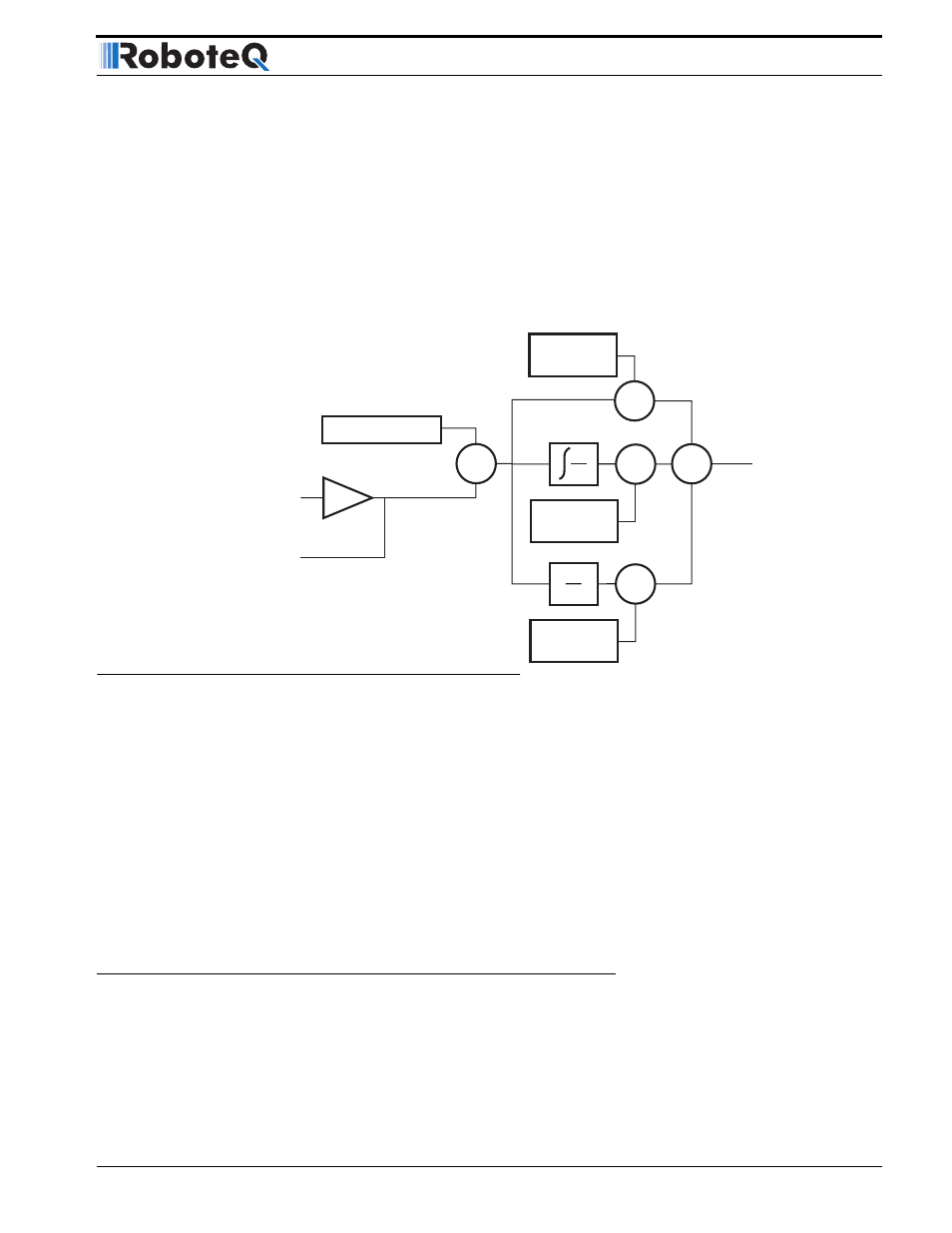

PID tuning in Position Mode

tance between the current and desired positions: when far apart, high power is applied,

with the power being gradually reduced and stopped as the motor moves to the final posi-

tion. The Proportional feedback is the most important component of the PID in Position

mode.

A higher Proportional Gain will cause the algorithm to apply a higher level of power for a

given measured error, thus making the motor move quicker. Because of inertia, however, a

faster moving motor will have more difficulty stopping when it reaches its desired position.

It will therefore overshoot and possibly oscillate around that end position.

The Differential component of the algorithm computes the changes to the error from one

16 ms time period to the next. This change will be a relatively large number every time an

abrupt change occurs on the desired position value or the measured position value. The

value of that change is then multiplied by a user-selectable Differential Gain and added to

the output. The effect of this part of the algorithm is to give a boost of extra power when

starting the motor due to changes to the desired position value. The differential component

will also help dampen any overshoot and oscillation.

The Integral component of the algorithm performs a sum of the error over time. In the posi-

tion mode, this component helps the controller reach and maintain the exact desired posi-

tion when the error would otherwise be too small to energize the motor using the

Proportional component alone. Only a very small amount of Integral Gain is typically

required in this mode.

PID tuning in Position Mode

As discussed above, three parameters - Proportional Gain, Integral Gain and Differential

Gain - can be adjusted to tune the position control algorithm. The ultimate goal in a well

tuned PID is a motor that reaches the desired position quickly without overshoot or oscilla-

tion.

Desired Position

Differential

Gain

Proportional

Gain

E= Error

Output

Measured Position

Analog Position

Sensor

or

Optical Encoder

A/D

-

x

Σ

x

dE

dt

Integral

Gain

x

dE

dt

FIGURE 42. PID algorithm used in Position mode