Installation check list, Caution ! warning – Rheem Commercial Power Direct Vent Water heater User Manual

Page 13

A. Water Heater Location

❑

Close to area of vent.

❑

Indoors and protected from freezing temperatures.

❑

Proper clearance from combustible surfaces observed and

water heater not installed on carpeted floor.

❑

Air supply free of corrosive elements and flammable vapors.

❑

Provisions made to protect area from water damage.

❑

Sufficient room to service heater.

B. Water Supply

❑

Water heater completely filled with water.

❑

Water heater and piping air vented.

❑

Water connections tight and free of leaks.

C. Gas Supply

❑

Gas line equipped with shut-off valve, union, and sediment

trap/drip leg.

❑

Approved pipe joint compound used.

❑

Soap and water solution used to check all connections and

fittings for possible gas leak.

❑

Gas Company inspected installation (if required).

D. Relief Valve

❑

Discharge line run to open drain.

❑

Discharge line protected from freezing.

E. Venting

❑

All pipe connections are secure (at blower, vent terminals and for

each pipe joint connection)

❑

Vent terminals mounted properly and in correct location.

❑

Condensate tube has water in both loops.

installation Check list

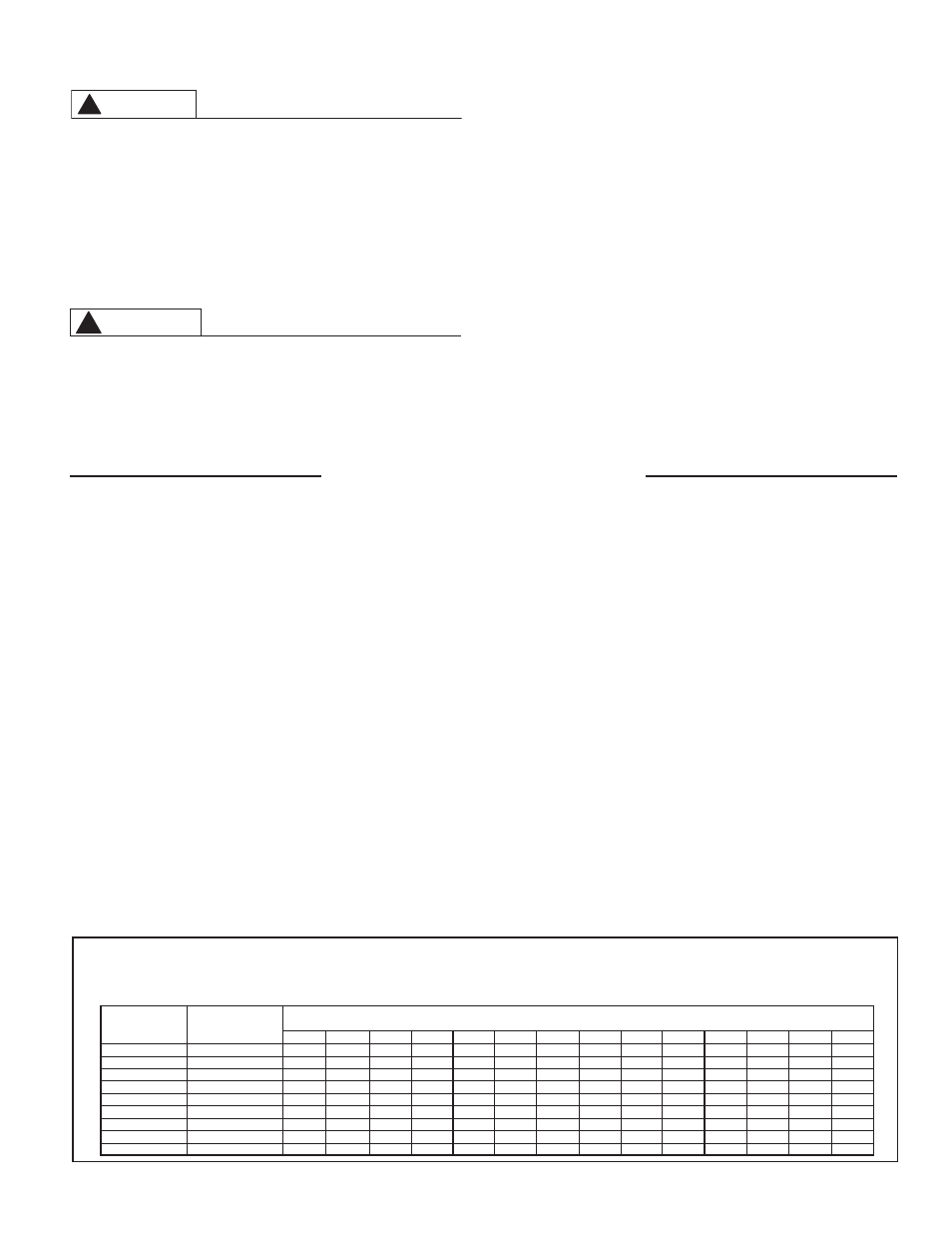

TABlE 1

maximum Capacity of Pipe in Cubic Feet of gas per hour for gas Pressures of

--------0.5 psig or less and a Pressure Drop of 0.3 inch Water Column

Based on a 0.60 Specific gravity Natural gas; if 1.5 Specific gravity l.P. gas is used, multiply capacity by 0.63

Nominal

internal

iron Pipe Size,

Diameter

inches

inches

10

20

30

40

50

60

70

80

0

100

125

150

175

200

1/2

.622

132

2

73

63

56

50

46

43

40

38

34

31

28

26

3/4

.824

278

10

152

130

115

105

6

0

84

7

72

64

5

55

1

1.04

520

350

285

245

215

15

180

170

160

150

130

120

110

100

1 1/4

1.380

1,050

730

50

500

440

400

370

350

320

305

275

250

225

210

1 1/2

1.610

1,600

1,100

80

760

670

610

560

530

40

460

410

380

350

320

2

2.067

3,050

2,100 1,650

1,450 1,270

1,150 1,050

0

30

870

780

710

650

610

2 1/2

2.46

4,800

3,300 2,700

2,300 2,000

1,850 1,700 1,600 1,500

1,400 1,250

1,130

1,050

80

3

3.068

8,500

5,00 4,700

4,100 3,600

3,250 3,000 2,800 2,600

2,500 2,200

2,000

1,850 1,700

4

4.026

17,500 12,000 ,700

8,300 7,400

6,800 6,200 5,800 5,400

5,100 4,500

4,100

3,800 3,500

Length of Pipe, Feet

13

FOR PROPER iNSTAllATiON:

•

DO NOT use solvent cement that has become

curdled, lumpy or thickened.

•

DO NOT thin solvent cement. Observe shelf

precautions printed on the containers.

•

For applications below 32°F use only low

temperature type solvent cement.

•

Appropriate solvent and cleaner must be used for

the type of vent pipe used (PVC, CPVC or ABS).

DANgER OF FiRE OR BODilY iNJURY – Solvent

cements and primers are highly flammable. Pro-

vide adequate ventilation and do not assemble

near heat source or open flame. Do not smoke.

Avoid skin or eye contact. Observe all cautions

and warnings on material containers.

6. WIRING — A polarized 120V 50/60 Hz power supply, with suitable

disconnect means, must be connected to the black and white leads

provided. The current draw by the Power Direct Vent unit is 1.5 Amps.

The water heater, when installed, must be electrically grounded in ac-

cordance with local codes, or, in the absence of local codes, with the

National Electrical Code, ANSI/NFPA 70 in the United States; or CSA

C22.1 Electrical Code, in Canada. Refer to Fig. 14 on page 26 & 27

of this manual for water heater internal wiring diagrams.

NOTICE: DO NOT use in conjunction with a GFCI.

CAUTION

!

WARNING

!