Hydronic heating – Raypak HI DELTA HD101 User Manual

Page 14

14

Low Temperature System

Heater requires minimum inlet temperature of 105°F.

Consult the following sections for piping details.

Temperature & Pressure Gauge

The temperature and pressure gauge is shipped loose

for field installation.

Hydronic Heating

Pump Selection

In order to ensure proper performance of your boiler

system, you must install a properly sized pump.

Raypak recommends using a 20°F ΔT as design ΔT.

(ΔT is the temperature difference between the inlet

and outlet water when the heater is firing at full rate).

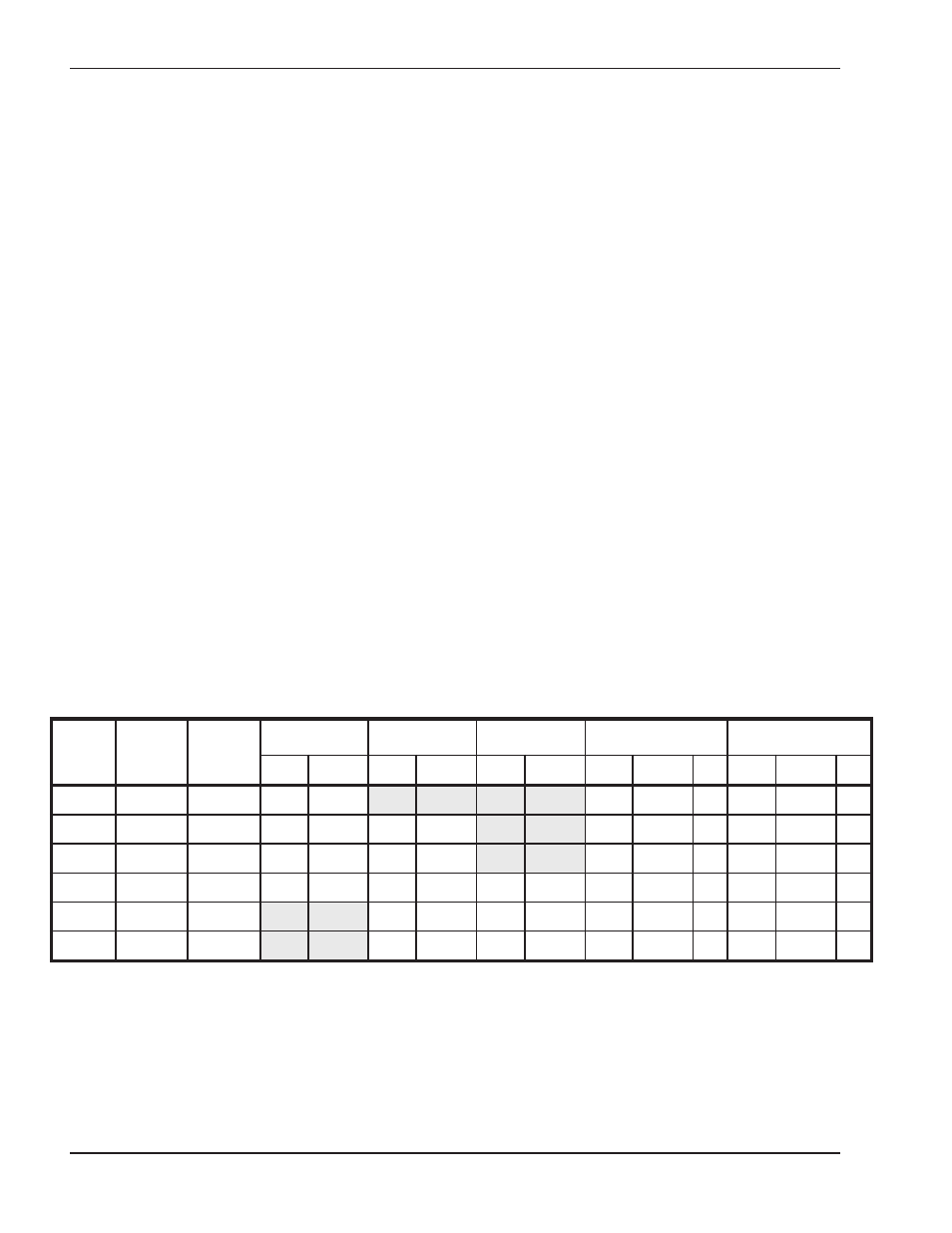

If a ΔT other than 20°F is necessary, see Table E for

flow rate requirements.

Pressure Drop in Feet of Head

Feedwater Regulator

Raypak recommends that a feedwater regulator be

installed and set at 12 psi minimum pressure at the

highest point of system. Install a check valve or back

flow device upstream of the regulator, with a manual

shut off valve as required by local codes.

Model

No.

Input

MBTUH

Output

MBTUH

10°F ΔT

20°F ΔT

30°F ΔT

Min. Flow

Max. Flow

gpm

ΔP (ft)

gpm

ΔP (ft)

gpm

ΔP (ft)

gpm

ΔP (ft)

ΔT

gpm

ΔP (ft)

ΔT

HD101

100

84

17

1.2

13

0.7

13

44

8.8

4

HD151

150

126

25

2.9

13

0.7

13

0.7

20

44

8.8

6

HD201

199

167

33

5.2

17

1.3

13

3.3

27

44

8.9

8

HD251

250

210

44

9.2

21

2.1

14

0.9

13

0.7

34

44

9.2

10

HD301

299

251

25

3.0

17

1.3

13

0.8

40

44

9.4

11

HD401

399

335

34

5.6

22

2.5

17

1.4

40

44

9.8

15

Table E: Heater Rates of Flow and Pressure Drops

*Flow switch will not activate at less than 12 gpm.

NOTE: Basis for minimum flow — 13 gpm or 40°F ΔT maximum flow — gpm, except for header.

Hydrostatic Test

Unlike many other types of heaters, Raypak heaters

do not require hydrostatic testing prior to being placed

in operation. The heat exchanger has already been

factory-tested and is rated for 160 PSI maximum oper-

ating pressure. However, Raypak does recommend

hydrostatically testing the piping connections to the

heater and the rest of the system prior to operation.

This is particularly true for hydronic systems using

expensive glycol-based antifreeze. Raypak recom-

mends conducting the hydrostatic test before

connecting gas piping or electrical supply.

Leaks must be repaired at once to prevent damage to

the heater. NEVER use petroleum-based stop-leak

compounds.

1. Connect fill water supply. Fill heater with water (be

sure bleed valve is open). When water flows from

bleed valve, shut off water. Close bleed valve.

Carefully fill the rest of the system, being sure to

eliminate any entrapped air by using high point

vents. Close feed valve. Test at standard operating

pressure for at least 24 hours.

2. Make sure constant gauge pressure has been

maintained throughout test.

3. Check for leaks. Repair if found.