Blade sharpening, Blade removal, Blade sharpening -5 blade removal -5 – Rhino Mounts SE42 User Manual

Page 129: Maintenance

MAINTENANCE

SE42 03/08

Maintenance Section 5-5

© 2008 Alamo Group Inc.

MAINTENANCE

BLADE SHARPENING

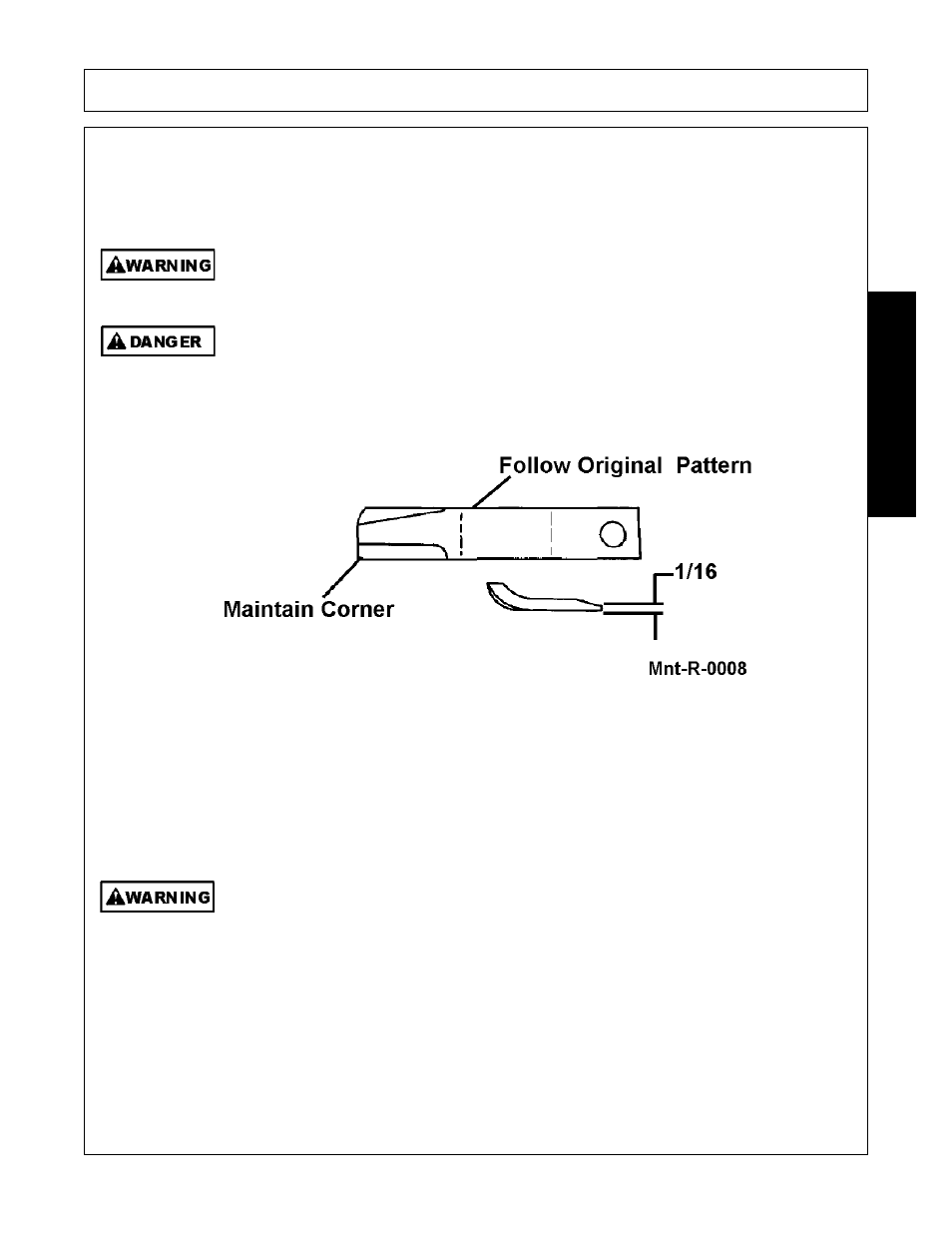

Always sharpen both blades at same time to maintain balance. Follow original sharpening pattern as shown in

Mnt-R-0008. Always sharpen blades by grinding. DO NOT heat and pound out edge. Do not sharpen blade to

a razor edge, but leave a 1/16” blunt edge. Do not sharpen back side of blade.

Avoid personal injury. Always block the cutter up to prevent if from falling when the blades

and / or carrier are being serviced.

Replace bent or broken blade with new blades. NEVER ATTEMPT TO STRAIGHTEN OR

WELD ON BLADES SINCE THIS WILL LIKELY CRACK OR OTHERWISE DAMAGE THE

BLADE WITH SUBSEQUENT FAILURE AND POSSIBLE SERIOUS INJURY FROM

THROWN BLADES.

(SGM-10)

BLADE REMOVAL

To remove blades for sharpening or replacement. Remove lock nut from blade bolt, by accessing through

blade bolt access hole on top of deck.

NOTE: Inspect lock nut after removal and replace if threads are damaged.

Always replace nut when replacing blade bolt. When installing blades be sure and check blade bolt pivot

diameter for wear. Replace bolt if worn more than 1/4 inch at any point. Tighten lock nut to 350 ft. lbs.

Avoid personal injury. Blade and/or blade carrier removal should be done only with the

tractor engine shut off, key removed, in neutral, parking brake on, and PTO disengaged and

the cutter blocked in the raised position.