Raypak 1005 User Manual

Page 44

4.

When firing at 100%, the desired heater combus-

tion CO2 is between 8.5 and 9.0% for natural gas

and 9.5 and 10.0% for propane with CO less than

100 ppm. If this combustion cannot be achieved

with the net blower suction within the tolerances

specified in Table W, contact the factory. The ref-

erence amp draw reading may help to indicate if

there is a problem with the system or if blower

adjustment is required.

Manifold Check

1.

Check manifold gas pressure at the gas valve out-

let pressure tap (connection “D” in Fig. 47). This

pressure should read per the values in Table X for

natural and propane gas.

2.

If the pressure reading differs by more than ± 0.2

in. WC, STOP – Call the factory for directions

on what to do next!

Blower Check

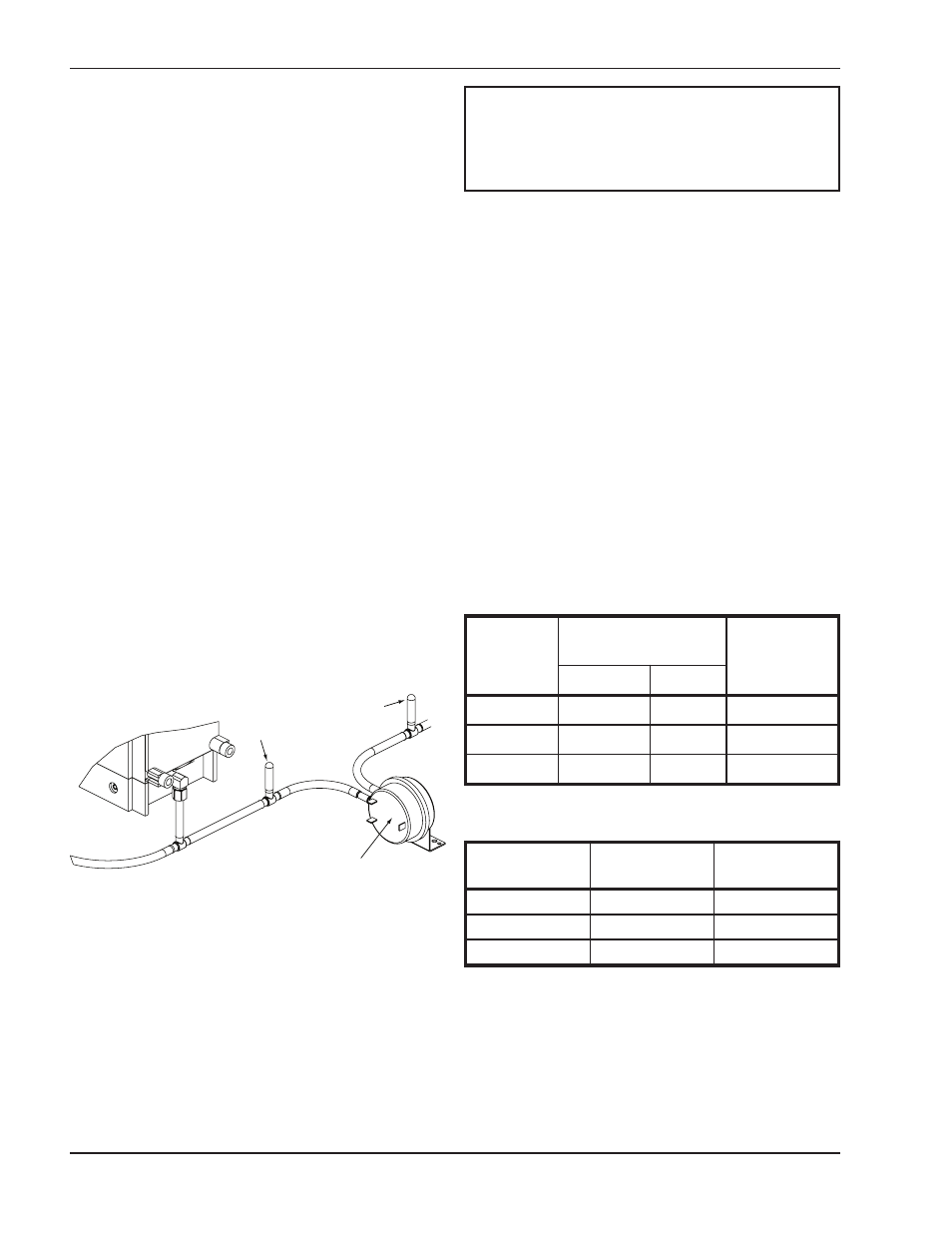

1. Check the net blower suction using a 6-0-6 U-tube

manometer by connecting one end to the blower

suction pressure tee (attached to the negative side

of the air pressure switch, point “A” in Fig. 48) and

the other end to the tracking pressure tee

(attached to the positive side of the air pressure

switch, point “B” in Fig. 48). Read the differential

pressure with the heater firing at 100% input and

compare to Table W.

2. Check the tracking pressure by removing the end

of the U-tube manometer from the blower suction

pressure tee (point “A” in Fig. 48). Replace the

cap on the blower suction tee and check the track-

ing pressure (at point “B” in Fig. 48) with the heater

firing at 100% input. The tracking pressure pro-

vides feedback to the gas regulator to compensate

for various air ducting arrangements and changes

in the pressure drop across the combustion air fil-

ter. Initial readings with a clean air filter installed

must be recorded on the “Start-up Checklist” locat-

ed at the back of this manual. When the tracking

pressure is more negative than -0.6 in. WC for

1005 and 1505 models or -0.8 in. WC on 2005

models and there are no obstructions to the air

intake, replace the combustion air filter. If the air

intake is obstructed, shut the unit off, clear the

obstruction, re-start and check the tracking pres-

sure as previously noted.

3.

FOR REFERENCE ONLY: Measure the blower

amp draw with the heater firing at 100% input and

compare the measured value to the values in

Table X. The amp draw is measured with a clamp-

on type amp probe clamped to the 14 AWG black

power wire going into the blower.

Table W: XTherm Air Pressure Settings

Model No.

Amp Draw

Setting

Tolerance

1005

4.8

+0.0/-0.2

1505

8.1

+0.0/-0.2

2005

13.0

+0.0/-0.5

Table X: XTherm Blower Amp Draw—Reference

Information

44

NOTE: Most commercially available amp probes

are not accurate enough and/or are not shielded well

enough to read accurately in the heater

environment. Blower amp draw readings are for

reference only.

Model No.

Net Blower Suction

(in. WC)

Setting

Tolerance

Nat.

Pro.

1005

-4.8

-2.8

± 0.2 in. WC

1505

-3.5

-3.5

± 0.2 in. WC

2005

-4.6

-5.0

± 0.2 in. WC

AIR PRESSURE SWITCH

A

B

Fig. 48: Air Pressure Measurement Locations