Raypak 1005 User Manual

Page 31

Operating Modes

Mode 1 – Not recommended.

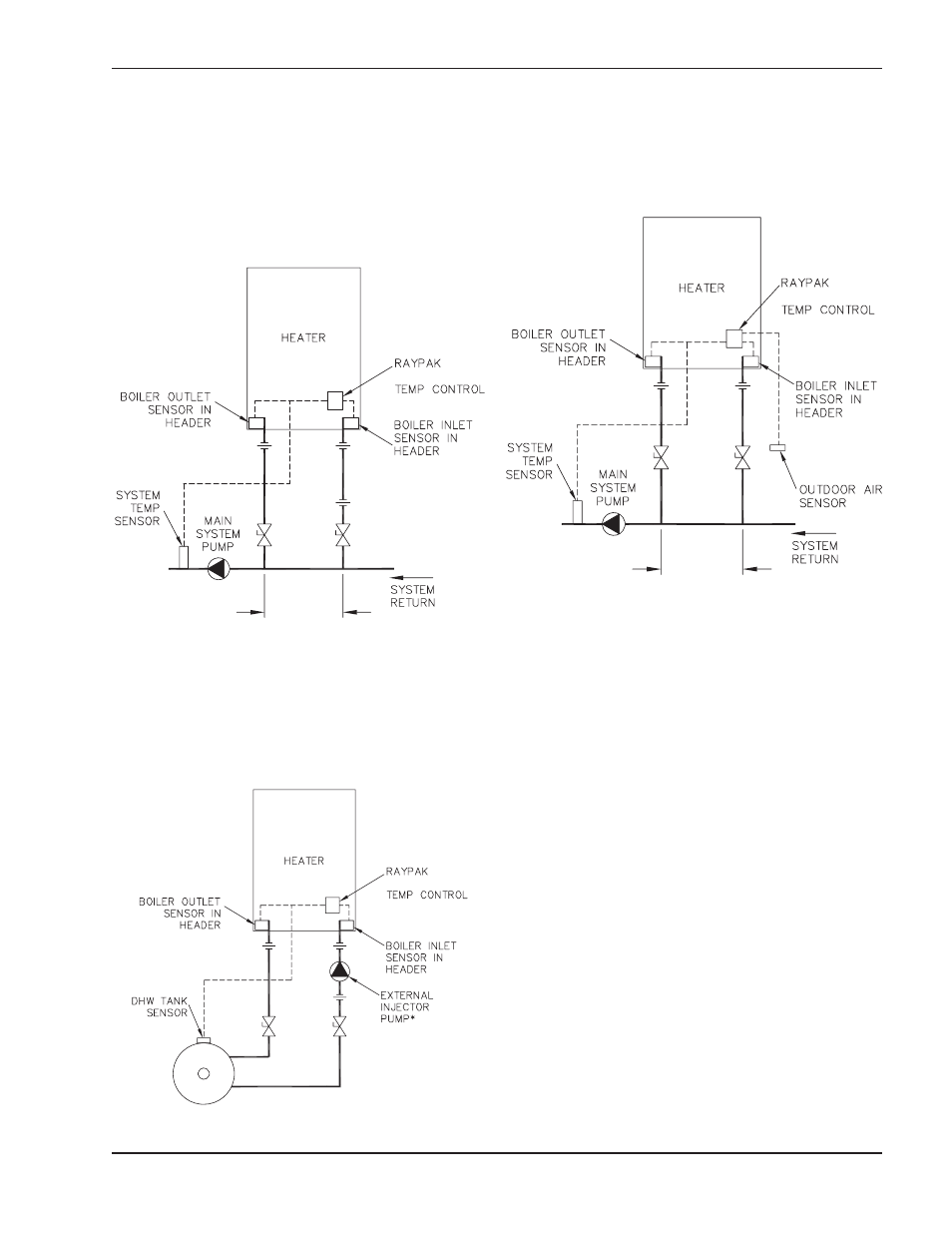

Mode 2 – Setpoint operation using primary/secondary

piping. The control operates the heater to satisfy a

remote system sensor. The heater is turned off based

on boiler max and boiler differential (factory default).

See Fig. 31.

Mode 3 – Dedicated DHW operation using UniTemp

80 piping. A call for heat is determined by the DHW

sensor and the DHW boiler target. The heater outlet

water is also controlled to the boiler target tempera-

ture. See Fig. 32.

Mode 4 – Not recommended.

Mode 5 – Outdoor reset using primary/secondary pip-

ing. The heater is operated as in Mode 2. However, the

target temperature is based on outdoor reset. See Fig.

33.

Mode 6 – Not recommended.

Mode 7 – Designed for an external input signal with

primary/secondary piping. The external input signal

can be provided from a BMS, an EMS or a sequenc-

ing control. The external input signal changes the

boiler target according to a linear scale. The control

operates the boiler burner to maintain the boiler target

at the remote system sensor. See Fig. 34 on the fol-

lowing page.

Mode 8 – This mode is used for remote control of the

heater. The Boil Max setting is the heater shutdown

temperature. The heater is enabled with a control sig-

nal ≥ 0.5 VDC. 0.5 VDC corresponds to minimum fire

an 10 VDC corresponds to 100% firing rate. The BOIL

MAX setting is the heater shutdown temperature.

31

MODULATING

*

Fig. 31: Mode 2 Primary/Secondary Piping

MODULATING

Fig. 32: Mode 3 Dedicated DHW

MODULATING

*

Fig. 33: Mode 5 Primary/Secondary Piping with

Outdoor Reset

*Maximum 4 times the pipe diameter or 12”, whichever is less.

*Maximum 4 times the pipe diameter or 12”, whichever is less.

*Some models.