Installation, Aeration adjustment – Regency Freestanding Gas Stove F39-LPG User Manual

Page 16

16

Regency

®

F39 Room Sealed Freestanding Gas Stove

Burner Inlet Orifi ce Sizes:

NG

LPG

Burner

#32

#50

2.95mm 1.78mm

Max. Input NG 40

Mj/h

LPG

38

Mj/h

Min. Input NG 20

Mj/h

LPG

19

Mj/h

Supply Pressure

NG

min. 1.13 kPa

LPG

min. 2.75 kPa

Manifold Pressure

NG

.94

kPa

LPG

2.55kPa

Electrical: 240 V. 1.13A 60Hz.

Circulation: 2 speed fan, 125/75 CFM.

Log Set: Ceramic fi ber, 7 per set.

System Data

F39 Converted to 31mj

Burner Inlet Orifi ce Sizes:

NG

#37 2.65mm

LPG

#52 1.6mm

Max. Input - NG/LPG

31

Mj/h

Min. Input - NG/LPG

16

Mj/h

Supply Pressure

NG

min. 1.13 kPa

LPG

min. 2.75 kPa

Manifold Pressure

NG

.89

kPa

LPG

2.55kPa

Electrical: 240 V. 1.13A 60Hz.

Circulation: Variable speed fan, 125/75

CFM.

Log Set: Ceramic fi ber, 7 per set.

System Data

F39 with 40mj

INSTALLATION

Note: To properly check gas pressure, both

inlet and manifold pressures should

be checked using the valve pressure

ports on the valve.

1) Make sure the valve is in the "OFF" posi-

tion.

2) Loosen the "IN" and/or "OUT" pressure

tap(s), turning counterclockwise with a 1/8"

wide fl at screwdriver.

3) Attach manometer to "IN" and/or "OUT"

pressure tap(s) using a 5/16" ID hose.

4) Light the pilot and turn the valve to "ON"

position. Read manometer.

5) The pressure check should be carried out

with the unit burning and the setting should

be within the limits specifi ed on the safety

label.

6) When fi nished reading manometer, turn

off the gas valve, disconnect the hose and

tighten the screw (clockwise) with a 1/8" fl at

screwdriver. Note: Screw should be snug,

but do not over tighten

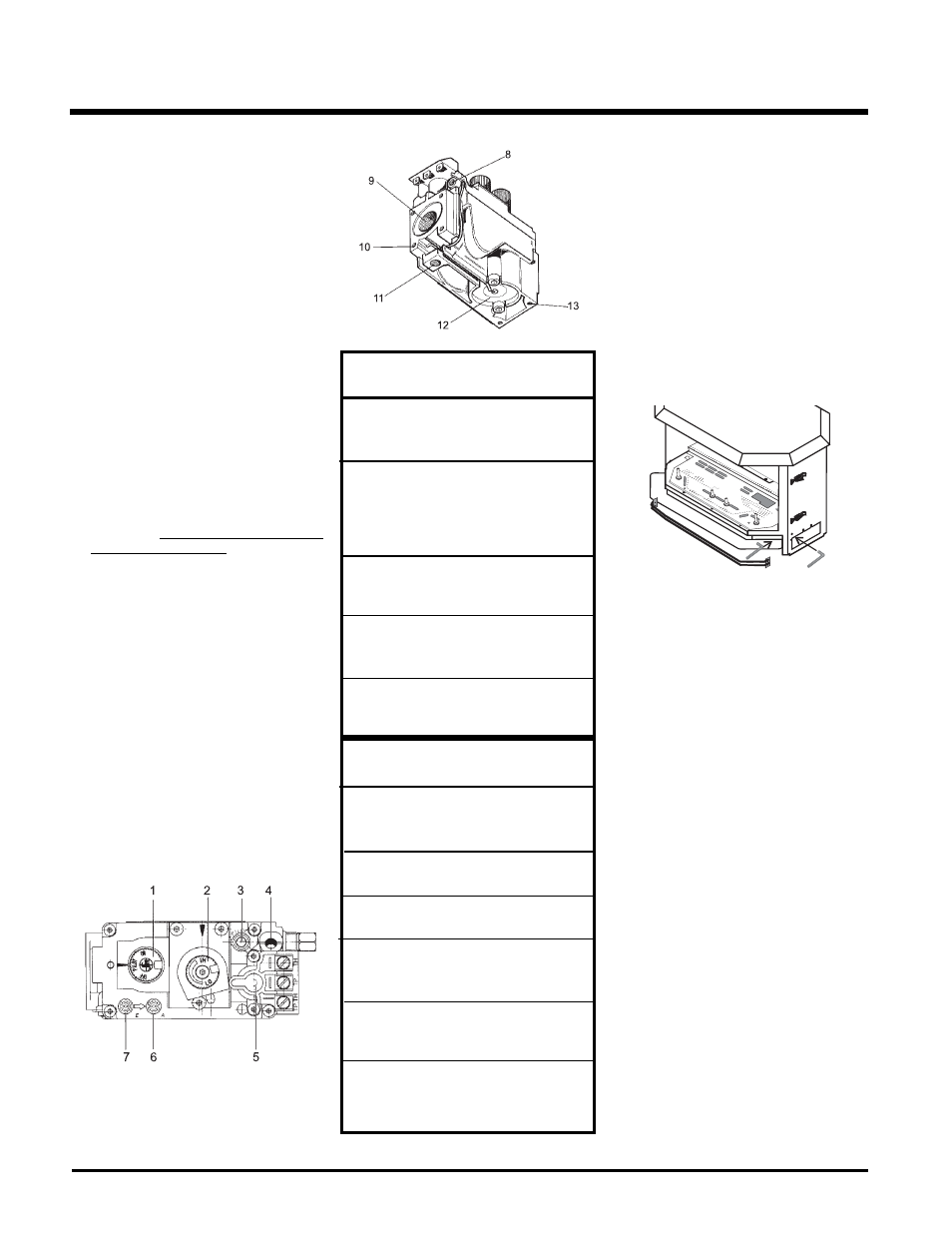

Valve Description

1) Gas

on/off

knob

2) Manual high/low adjustment

3) Pilot

Adjustment

4) Thermocouple

Connection

5) Main

Operator

6) Outlet Pressure Tap (Manifold

Pressure)

7) Inlet

Pressure

Tap

(Supply

Pressure)

8) Pilot

Outlet

9) Main Gas Outlet

10) Flange Securing Screw Holes

11) Alternative TC Connection Point

12) Thermoelectric Unit

13) Additional Valve Mounting Hole

AERATION

ADJUSTMENT

The burner aeration is factory set but may need

adjusting due to either the local gas supply or

altitude.

F39 with 40mj

F39-NG

NG:

Full open

F39-LPG

LPG:

Full open

F39 with 31mj

F39-NG NG

6mm

open

F39-LPG LPG

10mm

open

Note: Any

damage due to carboning resulting

from improperly setting the aeration

controls is NOT covered under war-

ranty.