8% less fuel, Saving on fuel, Designed and shaped to save money – New Holland FR9090 User Manual

Page 11

SAVING ON FUEL.

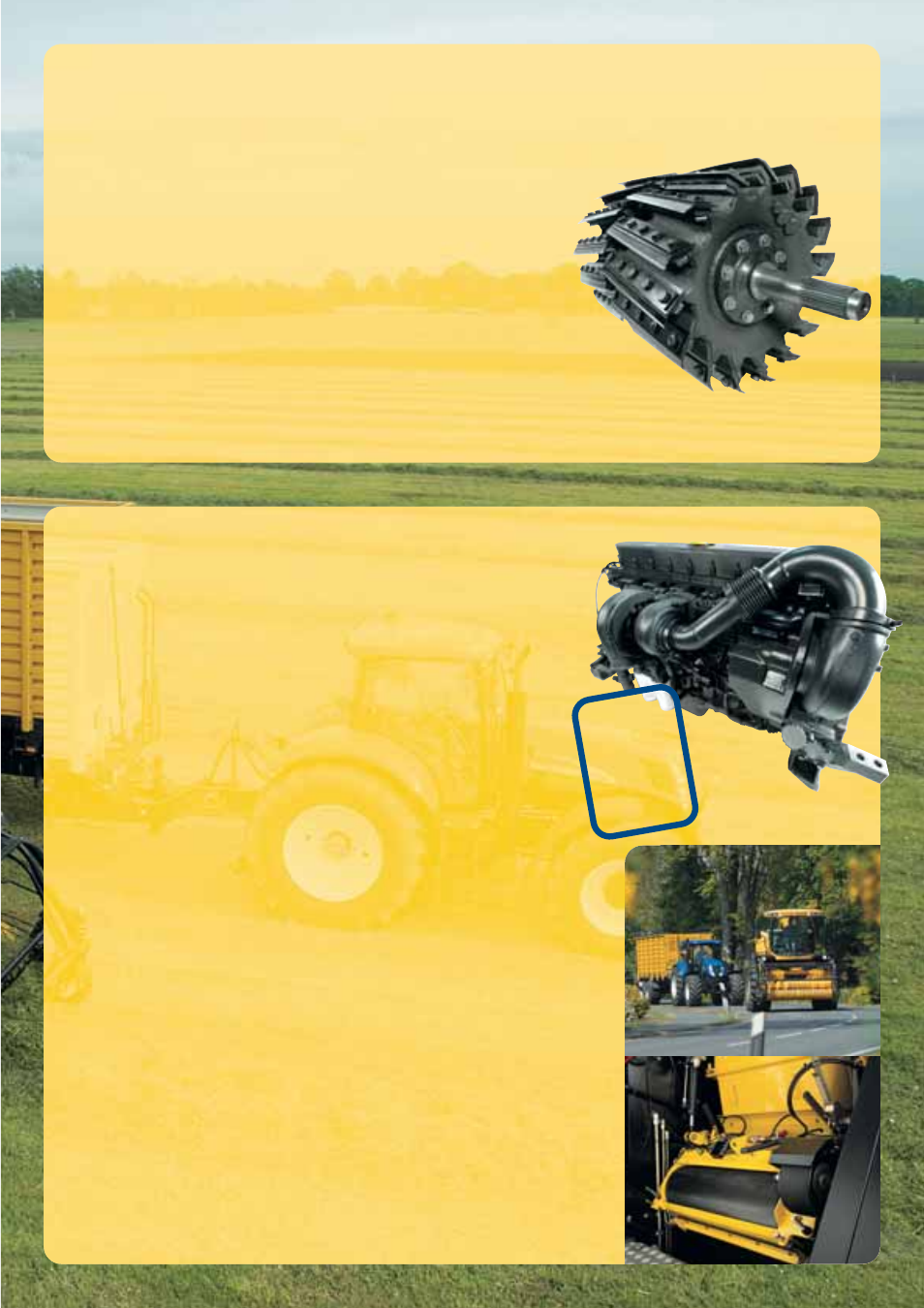

Engineered to save on fuel: Turbo compound engine

New Holland recognises the benefits of the Turbo Compound technology

and is the first brand to apply it in agricultural equipment. By using the

energy that is left in the exhaust gases leaving the turbo charger, this

state of the art technology reduces the fuel consumption by up to 8%

with the same engine power. On a high hp engine this means a saving

of many litres of fuel. The Turbo compound technology transmits

the power directly to the engine crankshaft via a hydrodynamic coupling.

It is applied on the FPT Cursor engine of the Model FR9060.

20% less fuel on the road

Tests have revealed that in road traffic, a fuel saving of 20% is achieved,

with the application of the Power Cruise™ II driving system. The engine

rpm drops automatically to the lowest possible value, with a minimum

of 1400rpm, without losing forward speed. On top of the important fuel

and money saving, the lower engine speed results in a much quieter

and more comfortable drive.

Variflow™ system strongly reduces fuel consumption in grass crops

Reducing the distance between cutterhead and blower by 60% when

working in grass, dramatically decreases the power requirement for

the blower. Unlike fixed blower concepts, the Variflow™ system maintains

the speed of the material, as it is transferred from cutterhead to blower:

there is virtually no requirement for re-acceleration of chopped material.

Tests have shown that the variable position blower reduces the power

requirement with around 30kW[40hp(CV)] when working in grass crops.

DESIGNED AND SHAPED TO SAVE MONEY.

Low power requirement for chopping: efficient chopping concept

The largest cutterhead in the industry runs smoothly thanks to its wide

cutting line. Spreading the crop over a wider intake reduces the layer

thickness and the power requirement for the cutting action.

Inertia of 600kg optimises the use of energy input

The inertia of the heavy cutterhead enhances the flywheel effect to compensate

for sudden peak loads. This results in a continuous chopping action and

an even engine pace and optimum fuel efficiency. A time saving characteristic

of the cutterhead is that its closed construction provides immediate emptying

of chopped material. No need to wait: the flow stops after 1 or 2 seconds.

8%

less

fuel